Yeast Trial with SO2 Resistant EC1118 (2014)

Kirsty Harmon

Blenheim Vineyards

Purpose:

Assess sensory attributes and fermentation kinetics of SO2 resistant EC1118 yeast. Method: Two tons of Chardonnay with identical sourcing was cleaned in the vineyard and then picked and whole cluster pressed. 10 g/HL of SO2 was added during pressing and another 5 g/HL added to the juice. Juice was racked to two identical Kelvin American Oak Medium 2011 barrels, one inoculated (42g/barrel) with EC118 yeast, the other with EC1118 SO2 resistant yeast. The pH adjusted to 3.2 with required amount of H2T, Juice allowed to warm to 55°F (13°C), and a molecular SO2 of 0.7mg/L was targeted (18mg/L FSO2). Fermentation was monitored daily. Results: Triangle testing indicated no significant discernable difference between trial and control groups, but distinct differences in fermentation kinetics. The trial group had different ending lab values as compared to the control group. This includes depress FSO2, acetaldehyde and acetic acid. Discussion: Triangle testing showed useful results, and perceived ancillary benefits (reduced acetic acid levels) of the trial yeast allow it to remain a consideration. Valuable future experimentation should include a similar trial on other varietals. Additionally, a similar protocol in a “bad weather” year may prove beneficial. Conclusion: The trial yeast did not significantly alter the flavor profile of the wine, and could potentially provide other benefits during and after fermentation.

Presented Jan 28, 2015 at Trump Winery

Keywords: Yeast, EC1118, ScottLab, SO2 resistance, Chardonnay, acetic acid

Introduction:

Under low nutrient conditions Lalvin EC1118TM can produce high amounts of SO2 (up to 50 ppm) and, as a result, may inhibit MLF. EC1118 SO2 resistant yeast may be able to provide similar sensory characteristics in the wine without the potential impairment of MLF. This experiment was designed to compare the sensory attributes and fermentation kinetics of the same wine fermented separately with these two yeasts. This will help to determine differences, if any, between the two yeasts and provide guidance to how and when these yeasts will be most beneficial to the wine maker.

Method:

Two tons of botrytis infected Chardonnay with identical sourcing was cleaned in the vineyard and then picked. After picking, the fruit was moved to the winery and whole cluster pressed. During pressing 10 g/HL of SO2 was added. Another 5 g/HL of SO2 was added to the juice after pressing, it was then cold settled at 35F overnight. After cold settling the juice was racked to two identical Kelvin American Oak Medium 2011 barrels.

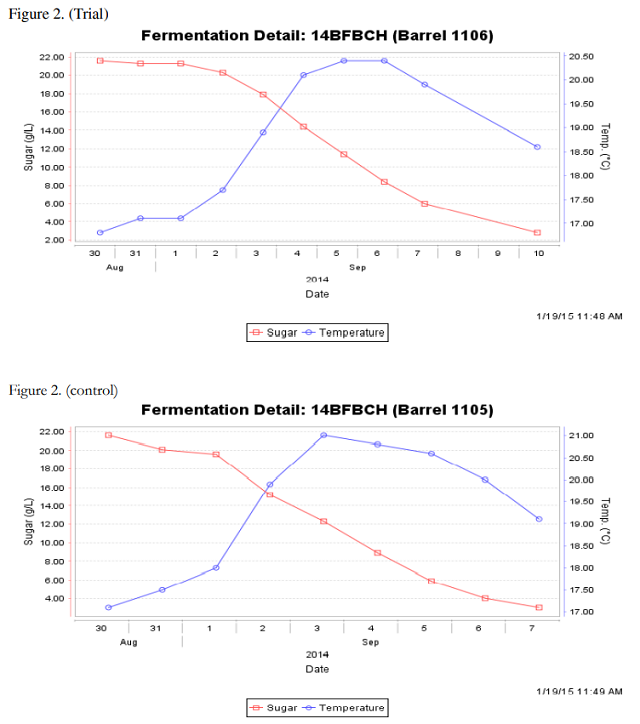

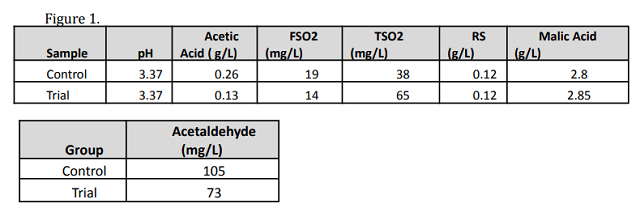

The first barrel was inoculated (42g/barrel) with EC1118 yeast (ScottLab), the other with EC1118 SO2 resistant yeast (ScottLab). The pH of both barrels was adjusted to 3.2 with the required amount of H2T. The juice was then allowed to warm to 55°F (13°C), and a molecular SO2 of 0.7mg/L (18mg/L FSO2) was targeted (Figure 1). Fermentations were monitored daily for Brix and temperature to determine lag time and to analyze kinetics.

Results:

Triangle taste testing indicated no statistically significant difference between trial and control groups (n=25).

Fermentation kinetics (Figure 2) showed obvious differences between the two yeasts. The trial yeast (EC1118 SO2 resistant) maintained a lower overall temperature through fermentation with less time spent at temperatures over 19C. Additionally the consumption of sugar in the trial group occurs in a sigmoidal fashion as opposed to a more linear fashion in the control group.

Post MLF lab analysis (Figure 3) shows the trial group has much lower levels of acetic acid, free SO2 and acetaldehyde as compared to the control. However, total SO2 remains higher in the control group.

Discussion:

This yeast trial is unique in that sensory attributes of the wine were tested, but the ideal hypothetical outcome would be no difference between the two wines. Lack of significant differences between groups shows that the SO2 resistant EC1118 and the control EC1118 bring similar characteristics to the wine as they are designed to do. In addition to not significantly altering the characteristics of the wine SO2 resistant EC1118 may provide ancillary benefits, making it a valuable tool under certain conditions.

For wineries that lack active cooling and heating and cooling methods, controlling fermentation temperature is an important consideration. Both the control and the trial finished AF at the same Brix, however the trial yeast accomplished this with a lower overall temperature. Conversely, for wineries with significant space issues, fermentation times may be of greater importance. Fermentation time was significantly extended (30%) with the trial yeast.

The finished wine produced using the trial yeast had a level of acetic acid that was 50% lower as compared to the wine using the control yeast. Though it is impossible to draw a causal relationship from this experiment, continued use of the EC1118 SO2 resistant yeast may show consistently reduced acetic acid levels in finished wine. This would be a valuable tool for winemakers, particularly in “bad weather” years.

Conclusion:

Further experimentation with the EC1118 SO2 resistant yeast will be necessary to validate the results seen here. However, these initial tests provide important information, and show a myriad of potential functions.

References

http://www.scottlab.com/product-57.aspx

http://www.murphyandson.co.uk/datasheets/tech_Lalvin%20EC-1118%20part%202.pdf