Use of specialized nutrient (Stimula Chardonnay) to increase aromatic expression in barrel fermented Chardonnay (2020)

Rick Tagg

Delaplane Cellars

Summary

Like many Virginia wineries, Delaplane produces multiple Chardonnay products: an aromatic, fruity expression of the variety with no new oak influence and a full-bodied expression with new oak and full malolactic fermentation. The purpose of this experiment was to determine if use of different yeast nutrient products, Fermaid O vs. Stimula Chardonnay (Scottlabs) led to differences in aromatic expression in Chardonnay. Manufacturer’s guidelines were followed for goals of “fermentation security” and “optimization of esters”. There were no notable differences in fermentation kinetics or chemistry of the finished wine. The wines were also not significantly different in a triangle test.

Introduction

Like many Virginia wineries, Delaplane produces multiple Chardonnay products: an aromatic, fruity expression of the variety with no new oak influence and a full-bodied expression with new oak and full malolactic fermentation. Specialized yeast nutrient products such as Stimula Chardonnay (Scottlabs) advertise the ability to boost yeast aromatic expression, specifically ester production, that may be useful in differentiating Chardonnay wine style.

Esters are fermentation-derived compounds that contribute to the aromatic intensity and complexity of wine1,2. They are predominantly formed during fermentation by the condensation products of other components of the wine matrix. Esters contribute significantly to the fruity and floral bouquet of young wines2. Most esters are not formed in grapes, but rather during fermentation by the action of yeast enzymes, therefore yeast selection and fermentation factors including yeast nutrients can have a significant effect on ester formation2.

According to the manufacturer (Scottlabs), Stimula Chardonnay is 100% yeast autolysate “formulated to supply the optimal levels of amino acids, sterols, vitamins and minerals known to optimize the aromatic yeast metabolism.”3 Internal research studies in Spanish Chardonnay comparing the use of Stimula Chardonnay vs. DAP showed increased levels of several aromatic esters including ethyl hexanoate (fruity, green apple, strawberry), ethyl octanoate (sweet, fruity, sour apple, burned beer), ethyl decanoate (oil, fruity, floral, soap) and 2-phyenylethyl acetate (flowery, rosey, fruity), leading to sensory increases in aromatic complexity, intensity, and freshness3. The purpose of this experiment was to determine if use of different yeast nutrient products led to differences in aromatic expression in Chardonnay. There were two treatments:

- nutrient additions to “fermentation security” (Fermaid O)

- nutrient additions to “production of esters” (Stimula Chardonnay)

Methods

Grapes were hand harvested on 9/18/20, chilled overnight, then whole cluster pressed to tank with the addition of 0.16 mL/L Color Pro in the press and 30 mg/L SO2, 30 g/hL Glutastar, and 40 g/hL Bactiless in the tank. Dry ice was used to blanket the juices during crush. Cuvée only (no press fraction) was used for this trial. A juice sample was sent to the Virginia Tech Enology Services Lab at the time of racking to determine YAN. The tank was racked off lees to a separate tank, then mixed to ensure homogeneity before transfer to barrels of comparable cooperage and age for fermentation. Juice was inoculated with 25 g/hL CY3079 yeast rehydrated in 30 g/hL GoFerm.

Nutrient additions were made according to the targets shown in Appendix A. The control wine followed instructions for “fermentation security” (30 g/hL Fermaid O at 1/3 sugar depletion) while the treatment followed instructions for “optimization of esters” (40 g/hL Stimula Chardonnay at 1/3 sugar depletion). All nutrient additions were done on 9/26. Barrels were placed in a cool cellar with a goal of keeping the temperature of the fermentation cool. At the completion of fermentation, barrels were racked with the addition of 66 mg/L SO2.

Sensory analysis was completed by a panel of 32 wine producers. Due to restrictions put in place during COVID-19, sensory analysis was completed using shipped samples. Each wine producer received three wines in identical bottles, filled on the same day, each coded with random numbers. Two of the bottles contained the same wine while the third bottle contained the different wine. Participants were asked to identify which wine was different (a triangle test). There were four tasting groups with the unique wine in the triangle test balanced among the groups. Participants were then asked to score each wine on a scale of 0 to 10 for overall aromatic intensity, fruit intensity, floral intensity, and chardonnay varietal character. Participants were also given open ended questions to describe the wines. Results for the triangle test were analyzed using a one-tailed Z test. Descriptive scores were analyzed using repeated measures ANOVA. Scores for descriptive characteristics were analyzed only from participants who were able to distinguish the two wines (those who answered correctly in the triangle test).

Results

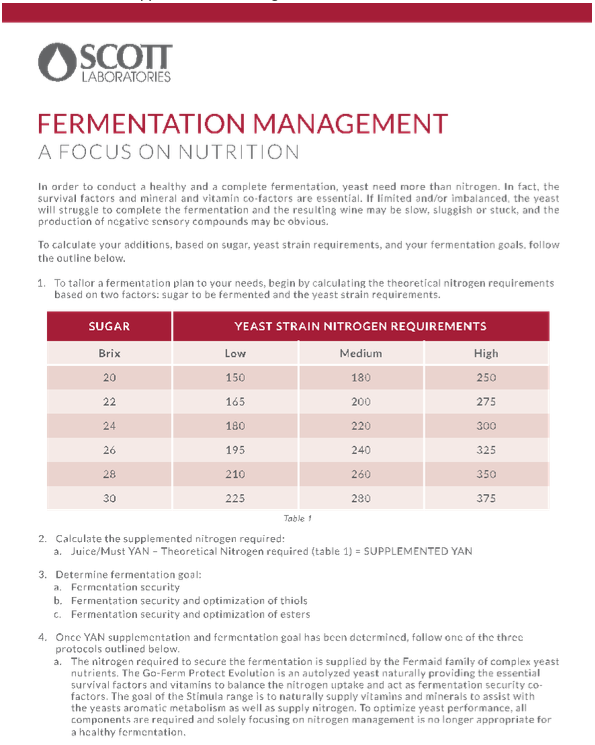

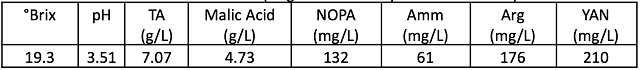

To determine the amount of nutrient to be added, a post-settling juice sample was sent to the Virginia Tech Enology Services Lab. The YAN was measured to be 210 mg/L (Table 1). The yeast strain, CY3079, is listed as having high nutrient requirements in the Scottlabs catalogue. According to the fermentation management guidelines provided by Scottlabs (Appendix A), 250 ppm of nitrogen is recommended for a fermentation beginning at 20°Brix with a yeast with high nutrient requirements. Accordingly, a small addition of nitrogen was planned to supplement. Using the charts provided in the Scottlabs Fermentation Management guidelines (Appendix A), a 30 g/hL Fermaid O addition was used for the control (fermentation security) while a 40 g/hL Stimula Chardonnay addition was used for the treatment (to optimize esters). Both additions were planned for approximately 1/3 sugar drop.

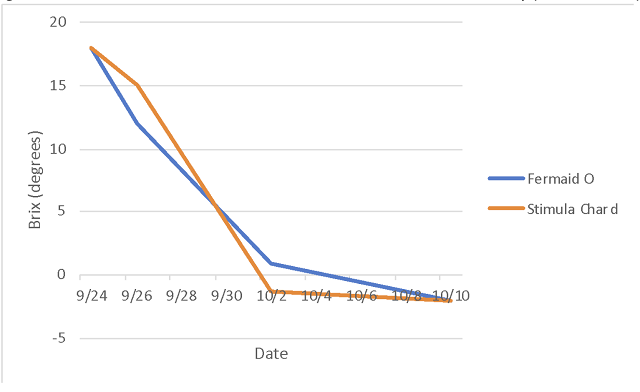

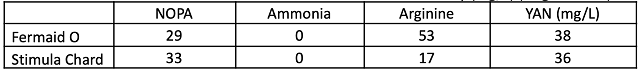

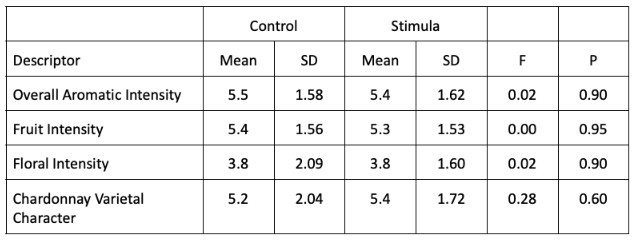

Fermentation kinetics were very similar for both treatments (Figure 1) and the finished wine chemistry was also very similar (Table 2). Both fermentations finished with no measurable residual sugar or lactic acid (data not shown) and comparable amounts of residual nitrogen (Table 3). In a triangle test, 13 out of 32 respondents were able to distinguish which wine was different, indicating the wines were not significantly different (Z=0.69, p= 0.25). There were no significant differences in scores for overall aromatic intensity, fruit intensity, floral intensity, or chardonnay varietal character (Table 4).

References

(1) Oberholster, A. Fermentation and Ester Taints, n.d.

(2) Jackson, R. S. Wine Science: Principles and Applications, 4 edition.; Academic Press: Amsterdam, 2014.

(3) Stimula Chardonnay Technical Data Sheet. Lallemand.

Table 1: Juice analysis. Samples were frozen prior to transport, so pH and TA numbers may be somewhat different. (Virginia Tech Analytical Services Lab)

Figure 1: Fermentation kinetics for two nutrient treatments in Chardonnay (in-house data)

Table 2: Finished wine chemistry for two treatments of Chardonnay (ICV Labs)

Table 3: Finished wine nutrients for two treatments of Chardonnay (mg/L) (Virginia Tech)

Table 4: Statistical analysis for descriptive scores from blind sensory analysis of two treatments of Chardonnay

Appendix A: Scottlabs guidelines for nutrient additions