Comparing protocols for thiol production in Sauvignon Blanc (Scottlabs) (2018)

Emily Pelton

Veritas Vineyard and Winery

Summary

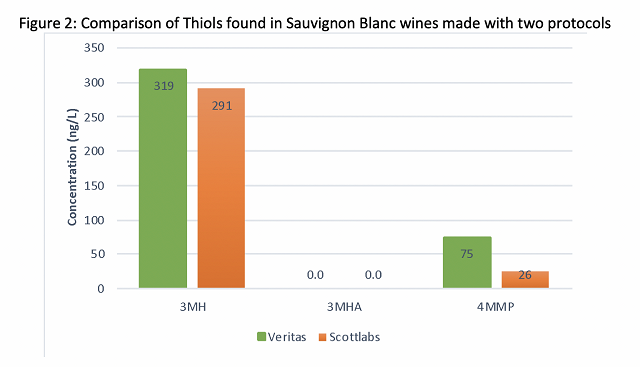

Thiols have become a defining characteristic of aromatic Sauvignon Blanc wines. Enological companies have developed specialized products to increase thiol production during fermentation and protection during aging. In this study, the standard protocol used at Veritas for production of Sauvignon Blanc is compared to the protocol recommended by Scottlabs. General wine chemistry was the same for both treatments. Wines were distinguished as different in a triangle test, with the Veritas protocol scoring higher in thiol intensity. Concentration of thiols and select esters were higher in the Veritas protocol wine.

Introduction

Grassy, bell pepper, box tree, broom, grapefruit and passionfruit are all descriptors used for the varietal character of Sauvignon Blanc. The chemicals that are responsible for this varietal character, 4MMP, 3MH and 3MHA have been described by Tominaga et al (1998). These chemicals are not present in grape juice, but rather precursors are transformed during the course of fermentation by yeast cells (Pinu et al 2012). The production of thiols requires that precursors are available in the fermentation and can be transported into yeast cells. Yeast cells must also have the cellular machinery to perform the transformation. As the base of knowledge surrounding production of aromatic thiols in Sauvignon Blanc (and other aromatic wines) has grown, so has interest in the mechanisms that convert precursors into aromatic compounds and how these can be used to maximize expression of thiols in the wine.

There are many steps in the course of production that affect thiol expression in the finished wine, including interventions in the vineyard as well as the winery. Scottlabs “Tropical (Thiol) Profile” protocol takes advantage of several of these steps to maximize expression of thiols and prevent them from oxidation, including targeting a higher level of turbidity after racking, inoculating with a thiol-producing strain of yeast (such as QA23 or Alchemy II), fermenting at a relatively warm temperature, use of a specialized yeast nutrient (Stimula Sauv Blanc) and addition of a glutathione-rich antioxidant.

The standard protocol for Sauvignon Blanc production at Veritas Vineyard and Winery already employs some of these principles. This experiment compares the wine produced by the standard protocol for the winery with that produced when multiple aspects of the Scottlabs protocol were employed to determine if additional steps should be included in the future. This experiment is a comparison of the protocol as a whole, with several factors differing between lots.

Methods

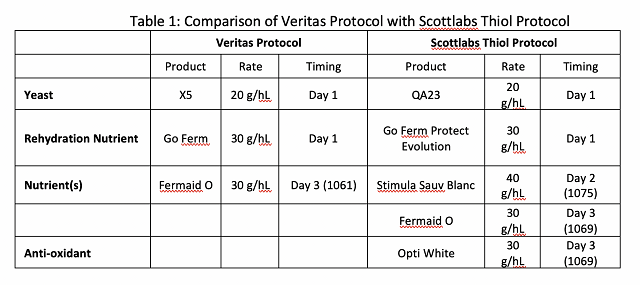

Fruit was crushed and destemmed into T-bins with an addition of 70ppm SO2. Bins were stored in a refrigerated environment overnight, then pressed with the press fraction cut at cycle 20. Juice was cold settled with the addition of 1.6 ml/hL Cinn Free for one day prior to racking to two stainless steel barrels. This was a small portion of a larger lot, so care was taken to avoid any bottom lees while racking. Both barrels were inoculated with 20 g/hL yeast rehydrated in 30 g/hL rehydration nutrient, and chaptalized with 0.5 g/L sugar the day after fermentation began. Table 1 shows the remaining additions to these barrels. Fermentations were monitored daily. At the completion of fermentation 45ppm SO2 was added.

Wines were tasted at sensory session conducted in January 2019 by 30 winemakers and other production staff. No formal training was conducted, however informal standards of “bell pepper”, “passionfruit”, “grapefruit” and “boxwood” were provided. All samples were presented in clear glasses with random three-digit numbers. Three glasses were presented, each with 2 ounces of wine. Panelists were asked to identify which of the three wines was different (a triangle difference test), then to evaluate each wine for thiol intensity. To prevent the dumping effect, panelists were also given two opportunities to write their own descriptors, in conjunction with the triangle test and in a comment box at the bottom of the scoring sheet.

Results

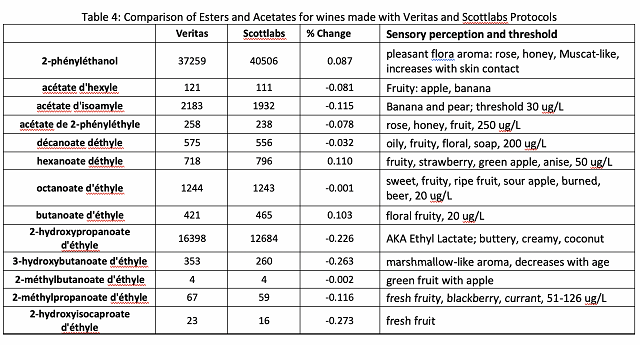

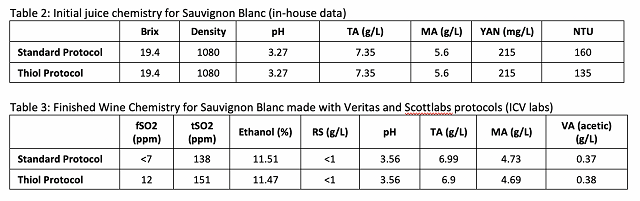

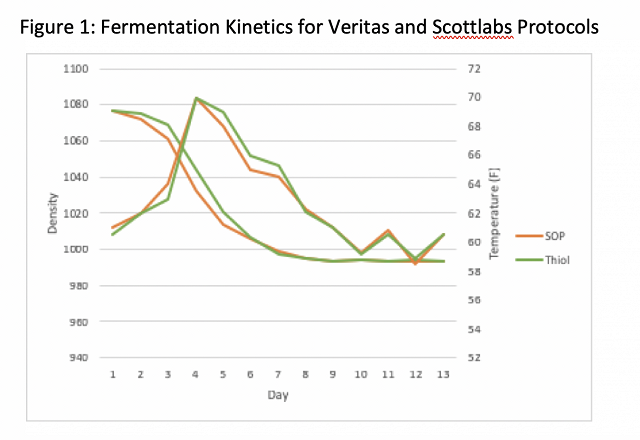

There was no difference in initial juice chemistry (Table 2). Fermentation kinetics (Figure 1) and finished wine chemistry (Table 3) were also very similar.

Concentration of three main thiol compounds, 3MH, 3MHA and 4MMP were measured by NYSEOS in March of 2019 (Figure 2). Two of the three (3MH and 4MMP) were found above the sensory threshold of detection in both treatments while 3MHA was not detected in these samples. The Veritas protocol had slightly higher 3MH but three times as much 4MMP. In a triangle test 25 out of 30 respondents were able to distinguish which wine was different. This is a significant difference (Z=5.62, p<0.001). The wine made with the Veritas protocol had a mean thiol intensity of 6.08 (SD=1.78) and Stimula Sauv Blanc had a mean thiol intensity of 4.92 (SD=1.42). These were significantly different (F=8.42, P=0.01). Esters were also analyzed by NSEOS in March of 2019 (Table 4). The largest proportional differences are lower levels of compounds lending fresh fruit and buttery/creamy/marshmallow sensations.

Summary

Wine made from the Scottlabs protocol was different from wine made from the Veritas protocol. The Veritas protocol wine had higher levels of 3MH and 4MMP and scored higher for thiol intensity. This wine also had slightly higher levels of select esters.

References

Pinu, F. R., S. Jouanneau, L. Nicolau, R. C. Gardner, and S. G. Villas-Boas. (2012) “Concentrations of the Volatile Thiol 3-Mercaptohexanol in Sauvignon Blanc Wines: No Correlation with Juice Precursors.” American Journal of Enology and Viticulture 63, 3: 407–12.

Tominaga, T., A. Furrer, R. Henry, and D. Dubourdieu. (1998). Identification of new volatile thiols in the aroma of Vitis vinifera L. var. Sauvignon blanc wines. Flav. Frag. J. 13:159-162.