Using glutathione to sustain thiol intensity during aging in Seyval (2021)

Theo Smith and Dani Bunce

Rappahannock Cellars

Summary

The purpose of this experiment was to test if use of Glutastar (Scottlabs) helped improve retention of aromas after fermentation in Seyval. Wine that received 30 g/hL Glutastar just after pressing was compared with wine fermentation without Glutastar. There were no consistent differences in odor active compounds (esters and acetates) nor oxidizable phenolics between treatments. Analysis of thiols and sensory analysis was not completed as wine had very low SO2 and noticeable pestilence in sample bottles.

Introduction

Stabulation has been incorporated into the standard protocol at Rappahannock to increase aromatic intensity of aromatic white wines with great success. However, some varieties lose aromatic intensity quickly after the end of fermentation. Increase in aromatic intensity due to stabulation is largely due to thiols, reduced sulfur compounds that can be easily oxidized to an odorless form. In a past WRE sensory session, Bruce Zoecklein mentioned that the single most important substance to retain aromatic intensity was glutathione. In 2020, Scottlabs began marketing Glutastar, a yeast derived nutrient high in the reduced GSH form of glutathione. GSH outcompetes several aromatic thiols (3MH, 3MHA, 4MMP) for oxidative orthoquinones, thus protecting these aromas. Manufacturer information indicates Glutastar should be added early, before fermentation, for maximum effect, and can have long-lasting positive impact on the varietal and fermentation aromas of the wine. In this experiment, juice from the same lot of Seyval was fermented with and without the addition of Glutastar just after pressing.

Methods

Fruit was whole cluster pressed to a single tank, then split into two equal tanks (750 gallons/2838 Liters each). One tank (treatment) received 30 g/hL Glutastar (851 g rehydrated in 8.5 liters of water). The other tank (control) did not receive this addition. Both tanks were stabulated for 7 days. On the eighth day of stabulation, 30 g/hL bentonite (851 g) was added to settle stabulation lees. The next day, 120 gallons of stabulated juice was racked to puncheons. The remaining juice was racked and returned to tank. The following day, juice was chaptalized with 25 g/L sugar to bring juice to 19.0 Brix. Both treatments were inoculated on 9/10 with 25 g/hL Cross Evolution yeast rehydrated in 30 g/hL Go Ferm. At the end of fermentation, puncheons were used to top fermentation tanks. Both tanks were treated with 30 ppm SO2.

Results

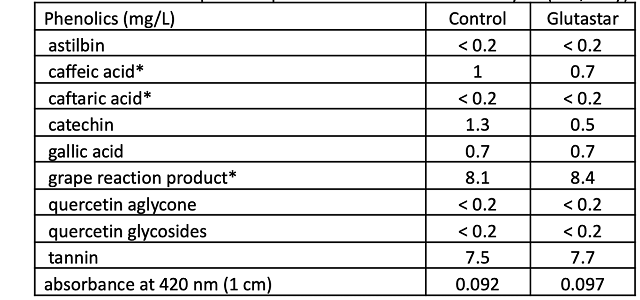

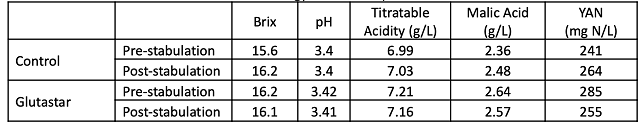

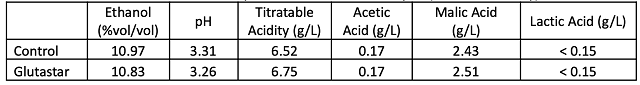

At harvest, in-house analysis showed juice had 16.5°Brix, a pH of 3.1 and titratable acidity of 8.1 g/L. Juice samples taken before and after stabulation show that stabulation alone causes no consistent notable changes in chemistry (Table 1). Differences in pH and TA between in-house and Virginia Tech samples are likely due to freezing of the juice sample. When juice is frozen, potassium bitartrate can form, leading to higher pH and lower TA values. YAN values are high enough that no nutrient was added to the fermentation. Samples bottles were taken prior to blending in December. Wine analysis in January indicated that there was no large difference in general chemistry between treatments (Table 2). Wine in the sample bottles was noticeably petillant, which precluded sensory analysis. Sulfur dioxide levels were <7 ppm, so differences in thiols may have diminished in the sample bottles. Alcohols, esters, and acetates, however, also contribute to wine aroma and are less oxygen labile. Analysis of these components showed many odor-active compounds present in these wines. Though there were small differences between the wines, there was not a consistent trend in differences between control and treatment wines (Table 3).

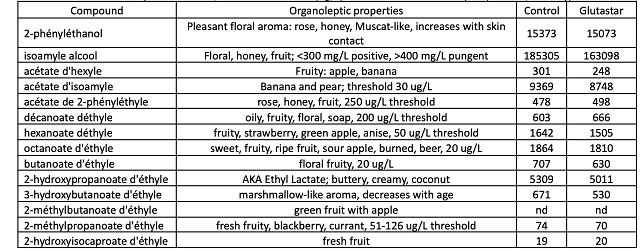

The mechanism of action of Glutastar is to outcompete several aromatic thiols (3MH, 3MHA, 4MMP) for oxidative orthoquinones. White wines contain several phenolics that might be subject to oxidation. Caftaric acid is a hydroxycinnamic acid found in the pulp of grapes that, when oxidized, releases caffeic acid. Grape Reactive Product is also a production of the oxidation of caftaric acid. As wine is oxidized, caftaric acid decreases, caffeic acid and GRP increase. All three of these molecules can be measured with a white wine phenolic panel (Table 4). In this case, there is slightly less caffeic acid in the Glutastar treated wine, however, this same wine has higher levels of Grape Reactive Product, indicating the opposite. Oxidation can also be seen in the absorbance at 420 nm. The Glutastar treated wine does not have lower absorbance than the control wine. In the case of Seyval at Rappahannock, treatment with Glutastar did not produce measurable differences in aroma compounds.

Table 1: Juice chemistry before and after stabulation for two treatments of Seyval (Virginia Tech Enology Services lab)

Table 2: Wine chemistry for two treatments of Seyval (ICV labs, January)

Table 3: Analysis of alcohols, esters and acetates (ug/L) for two treatments of Seyval (NYSEOS, January)

Table 4: White wine phenolic panel for two treatments of Seyval (ETS, May)