Reducing Bentonite use in Vidal (2019)

Lee Hartman

Bluestone Vineyards

Summary

Vidal Blanc is a hybrid grape variety resulting from a cross between Ugni Blanc and Seibel 4986 that has many characteristics that recommend it to Virginia grape growing 1. As a hybrid grape, Vidal often carries high levels of protein in the wine, leading to high bentonite additions prior to bottling, potentially stripping aromas and flavor. The purpose of this experiment was to determine if the addition of bentonite during fermentation reduces the need for bentonite addition later. One tank of fermenting Vidal was treated with 35 g/hL KWK while another fermented without bentonite. Both tanks completed fermentation fully stable without need for additional bentonite, an unusual outcome in Virginia Vidal. There were no sensory differences detected between the wines. One drawback of using bentonite is that it is not known how unstable the wine will be, leading to the risk of overfining. However, as seen here, fermentation on bentonite even when it was not needed did not decrease sensory characteristics.

Introduction

Vidal Blanc is a hybrid grape variety resulting from a cross between Ugni Blanc and Seibel 4986 that has many characteristics that recommend it to Virginia grape growing 1. Despite its prowess in the vineyard, wines made from hybrid grapes in general, and Vidal specifically, are often priced lower than those made from Vinifera grapes. In an effort to increase profitability of hybrid grapes by making quality wines, Bluestone is interested in production methodologies to make the most of the Vidal they grow.

As a hybrid grape, Vidal often carries high levels of protein in the wine, leading to high bentonite additions. Bentonite addition includes volume loss as well as potential flavor stripping. Common wisdom claims that the addition of bentonite during fermentation results in less loss of aromas than addition to finished wine. The focus of this experiment was to determine if the addition of bentonite during fermentation reduces the need for bentonite addition later. Also, to test if aroma and flavor differ depending on the timing of bentonite addition (during fermentation vs. addition to the finished wine).

Methods

There were two treatment categories in this experiment. The control followed the standard procedure of the winery with no bentonite addition during fermentation. The treatment included the addition of 35 g/hL bentonite during fermentation. All other winemaking procedures were followed according to the SOP of the winery with the single exception of bentonite addition.

Fruit was hand harvested and refrigerated overnight prior to processing. All fruit was pressed with addition of 40 ppm SO2 and 1.6 ml/hL Cinn Free, 10 g/hL FT Blanc, then settled as a single lot. Juice was settled for 4 days at 40 °F. After settling, juice was racked to a clean tank, then separated to fermentation tanks to ensure homogeneity. Both tanks received 30 g/hL Opti White after racking. Fermentations were temperature controlled to a maximum temperature of 60°F. There were no acid or sugar additions. Both lots were inoculated with 20 g/hL Alchemy I rehydrated in 15 g/hL Go Ferm. Fermentations were monitored daily for Brix depletion and temperature, with pH monitoring three times per week. Nutrients (Fermaid) were added at the beginning of fermentation and at ⅓ Brix depletion, according to manufacturer’s instructions (Scottlabs). At 1/3 brix depletion, 35 g/hL KWK bentonite was added to the treatment tank only. At the completion of fermentation, wine was racked to a clean tank and 50 ppm SO2 was added. SO2 was monitored monthly.

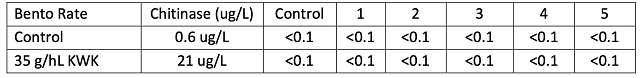

After completion of fermentation, a bentonite trial was completed at ETS labs to determine the amount of bentonite needed to achieve protein stability, as defined by a change in NTU <2.0. (ETS uses a heat test of 80°C for 6 hours.) Both wines used for sensory analysis were protein stabilized according to the outcome of this test.

Sensory analysis was completed by a panel of 28 wine producers. Wines were presented blind in randomly numbered glasses. Tasters were presented with three wines, two of one type and one of another, and asked to identify which wine was different (a triangle test). There were three tasting groups with the unique wine in the triangle test balanced between groups. Tasters were then asked to score each wine on a scale of 0 to 10 for aromatic intensity, fruit intensity, and palate volume. They were also given open ended questions to describe the wines. Results for the triangle test were analyzed using a one-tailed Z test. Descriptive scores were analyzed using repeated measures ANOVA.

Results

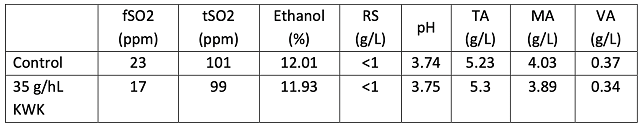

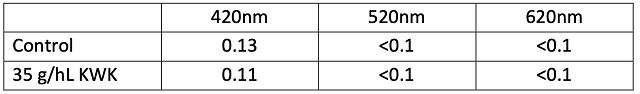

Fruit was harvested at 22°Brix with a pH = 3.4. There was no noticeable difference in progress of fermentation, with the bentonite fermentation finishing one day after the control (data not shown). There was little difference in primary chemistry of the wines after fermentation (Table 1). There was no measurable difference in color (a measure of potential oxidation) (Table 2). Both wines were protein stable, with the control wine having less chitinase than the wine fermented on bentonite (Table 3). There was no noticeable difference between the volume of wine lost during racking due to bentonite addition. There was <0.5" difference in a 2000L tank, 81" tall, which calculates to less than 12 liters of wine.

In a triangle test of experimental wines, 24 out of 28 respondents were able to distinguish which wine was different, indicating the wines were significantly different (Z=5.68, p= 0.003), however several tasters indicated that the wines were different in turbidity, obscuring this result. There were no significant differences in scores for aromatic intensity, fruit intensity, or palate volume. One drawback of using bentonite is that it is not known how unstable the wine will be, leading to the risk of overfining. However, as seen here, fermentation on bentonite even when it was not needed did not decrease sensory characteristics.

Table 1: Primary Chemistry (ICV Labs Jan 2020)

Table 2: Color of finished wine (ICV Labs Jan 2020)

Table 3: Bentonite Fining Trial (ETS Labs, Jan 2020)

Reference

(1) Wolf, T. K. Wine Grape Production Guide for Eastern North America; Plant and Life Sciences Publishing: Ithaca, New York, 2008.