Exploring chemical and sensory consequences of barrel fermentation in Petit Manseng (2021)

Skip Causey & Hope Nastry

Potomac Point

Summary

In Virginia, a growing number of winemakers are producing Petit Manseng as a dry table wine. This variety tends towards high sugar, high acid, and high tropical fruit character that can be difficult to balance in a dry style wine. The purpose of this set of experiments was to explore three avenues of fermentation of Petit Manseng in a dry style: tank, alcoholic fermentation in barrel, alcoholic and malolactic fermentation in barrel. At the completion of fermentation, pH and acetic acid were very similar among treatments. The tank fermented wine had lower titratable acidity and potassium, presumably due to precipitation of potassium bitatrate during tank cooling. Despite inoculation, barrels intended for malolactic fermentation had the same malic acid concentration as non-inoculated barrels that had been treated with SO2, indicating no malolactic fermentation occurred. Barrel fermented wines received significantly higher descriptive sensory scores for aromatic intensity and body/volume than tank fermented wine, however there were no significant difference in perception of balance in any of the wines.

Introduction

Petit Manseng is a white fruited variety of Vitis vinifera that originated in the Pyrenees-Atlantiques of Southern France and has its largest plantings in the Jurançon1,2. Petit Manseng was introduced to Virginia by Dr. Tony Wolf in 1987 as part of vineyard variety trials and has become popular among grape growers for its loose clusters, thick skins, and resistance to bunch rots1. In the last 30 years, popularity has grown such that Virginia now boasts the second largest planting of Petit Manseng in the world with more than 62 acres of Petit Manseng planted around the state3.

In its home region, Petit Manseng is most often blended with Gros Manseng and made as an off dry or dessert wine. These wines are described as having unique fruity and spicy aromas such as pineapple, peach, melon, grapefruit, nutmeg, honey, wildflowers, box tree, and roasted coffee bean4. Notable levels of thiols5 and esters6 have been measured in wines made from Petit Manseng grapes and contribute to these descriptors.

In Virginia, a growing number of winemakers are producing Petit Manseng as a dry table wine. The high sugar and high acidity this grape variety can achieve can be a challenge for dry wines, however it is also one of the most resilient varieties to the occasional/frequent rain during the growing season. Potomac Point has been producing Petit Manseng for 4 years, with each year having a difference in style ranging from 0 - 2% residual sugar. The team appreciates that the fruit has low disease pressure and grows well in Virginia1. They also like the wildly fruity, floral, and acidic nature of this variety. They are interested in developing an approach to produce a consistent dry style wine without imbalance in alcohol and acid.

Several previous WRE experiments have explored winemaking approaches to achieve balance in dry Petit Manseng including:

-

The effect of juice dilution (Emily Hodson, Veritas Vineyards and Winery)

-

Harvesting timing (Ben Jordan, Early Mountain Vineyards & Jordan Harris, Tarara Vineyard)

-

Hyperoxygenation to tame tropical aromas (Ben Jordan, Early Mountain Vineyards)

-

Skin Contact to reduce acidity (Cory Craighill, Sunset Hills Vineyard)

-

De-acidifying yeast (Nate Walsh, Walsh Family Wine & Matthieu Finot, King Family Vineyards)

Other approaches that might help balance the acidity, alcohol and tropical nature of this variety are barrel fermentation and malolactic fermentation. Barrel fermentation may allow for lower perception of acidity due to lees contact while micro-oxygenation may help moderate thiol-driven tropical notes. Malolactic fermentation would further decrease the perception of acidity and may bring additional complexity.

The purpose of this set of experiments was to explore three avenues of fermentation of Petit Manseng in a dry style:

-

Tank fermentation

-

Barrel fermentation with no malolactic inoculation

-

Barrel fermentation with sequential inoculation for malolactic fermentation

Methods

Grapes were hand harvested on 9/28 and chilled overnight, then whole cluster pressed on 9/29 with the addition of 3 g/hL Egide non-Saccharomyces yeast (Laffort), 30 g/hL SuperBouquet Evolution (Agrovin) and 15 g/hL Tanin Galacool (Laffort). To ensure the best environment for malolactic fermentation in one of the treatments, no SO2 was used at crush. After pressing, juice was cold settled for three days until clear. Juice was racked off lees to a separate tank and allowed to begin warming prior to transfer to fermentation vessels (stainless steel tank and 6 barrels). For each of the barrel fermentations, three identical barrels were used. Because Potomac Point did not have neutral white barrels, the barrel fermentations were all carried out in new barrels of the same toast level from the same cooper and forest.

Each fermentation was inoculated on the same day with 25 g/hL Zymaflore X-16 yeast (Laffort) rehydrated in 25 g/hL SuperStart Blanc. X-16 is marketed as producing fruity/floral aromas (esters) with good fermentation security. It is alcohol tolerant to 16%. Fermentation was monitored daily for sugar depletion and temperature. Nutrient additions of Superfood and Thiazote PH were made on 10/8. Wine was fermented to dryness. At the completion of alcoholic fermentation, wine in the tank fermentation was chilled to 40°F. Wine from treatments 1&2 received SO2 to achieve a target free SO2 of 25ppm and aged on lees with monthly SO2 monitoring. The three barrels designated for malolactic fermentation were not treated with SO2. These were inoculated on 10/24 with Lactoenos® B16 Standard (Laffort). ML bacteria were rehydrated according to the manufacturer’s protocol but with acclimatization for 24 hours rather than 3 days as noted in the protocol). Barrels that were inoculated with malolactic bacteria received no SO2 additions until the time samples were taken for sensory analysis.

Sensory analysis was completed by a panel of 32 wine producers. Due to restrictions put in place during COVID-19, sensory analysis was completed using shipped samples. Each wine producer received three wines in identical bottles, filled on the same day, each coded with random numbers. There were four tasting groups. Participants were asked to score each wine on a scale of 0 to 10 for aromatic intensity, fruit intensity, thiol intensity, body/volume, and balance. They were also given open ended questions to describe the wines. Descriptive scores were analyzed using repeated measures ANOVA. Descriptors with p vales less than 0.05 were further analyzed using Tukey’s HSD analysis of differences.

Tastry Analysis was also done on this wine. Tastry uses analytical chemistry and automated feature engineering to describe the flavor matrix of wine. AI systems integrate concentrations, thresholds and interactions of hundreds of compounds found in the wine matrix to predict the overall sensory characteristics of the wine as well as how well that wine will be received by consumers.

Results

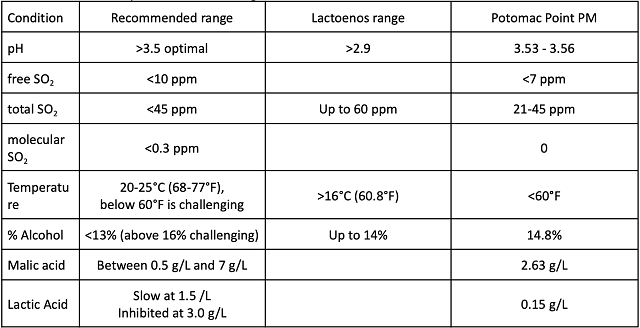

Fruit chemistry for this experiment was considerably more balanced than some vintages and source sites for Petit manseng (Table 1). The pH was determined from a frozen sample, and therefore is likely higher than the actual value due to tartrate precipitation.

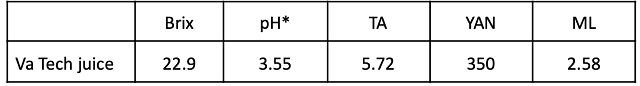

Fermentation was robust and complete for all treatments (Figure 1). The tank fermentation had a longer lag phase and cooler temperature than the barrel fermentation. The tank fermentation temperature peaked at 66°F while the barrel fermentation peaked at 71°F, with overall higher heat throughout fermentation in the barrel. The barrel fermentation was complete after 15 days. The tank fermentation was complete after 17 days.

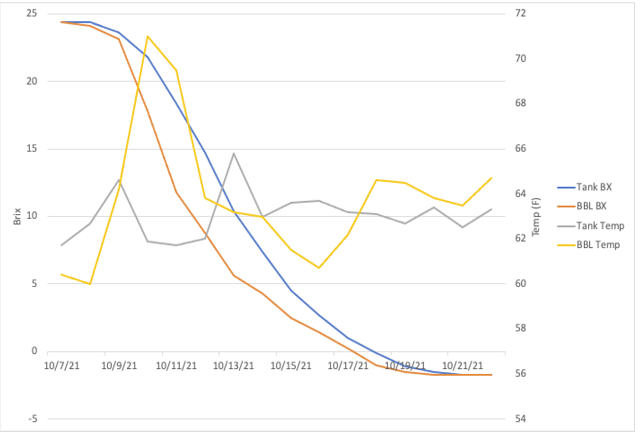

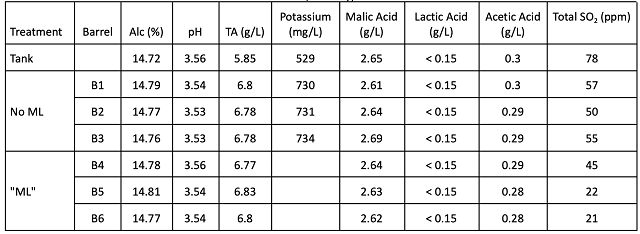

Post-fermentation chemistry was used to assess differences due to fermentation alone, and to ensure the barrels that were inoculated for malolactic fermentation had comparable starting chemistry to those that were sulfured after fermentation (Table 2). Each fermentation regime yielded similar levels of acetic acid. More malic acid was retained in the tank fermentation than any of the barrel fermentations.

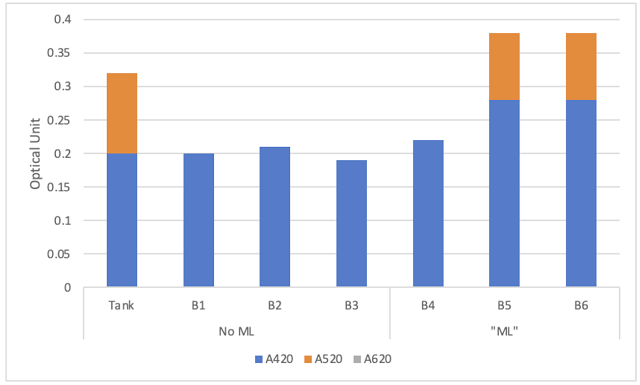

Wine chemistry was assessed again in January, shortly before the wines were to be blended for bottling (Table 3). Alcohol conversion rates and pH were similar for all treatments. The tank fermentation had lower titratable acidity and potassium, presumably due to storage at lower temperature leading to precipitation of potassium bitartrate. None of the barrels that were inoculated for malolactic fermentation showed any conversion of malic acid to lactic acid. At the time chemistry was taken, these barrels had higher levels of color intensity (i.e. browning)(Figure 2), however they had not yet been treated with SO2. The ML inoculated barrels remained unsulfured for 3 months longer than the “no ML” barrels.

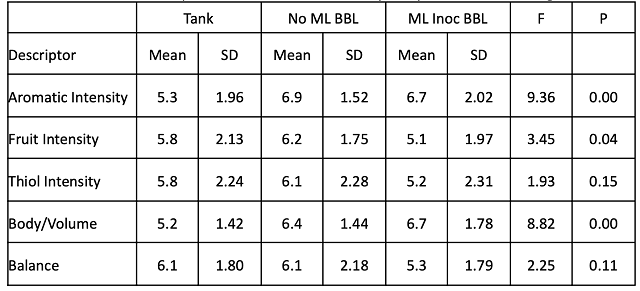

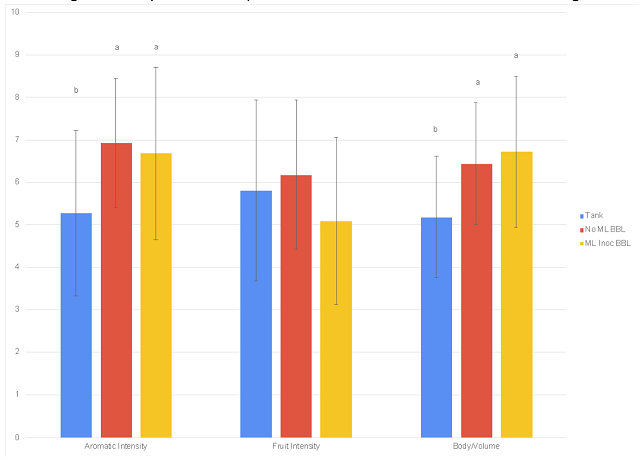

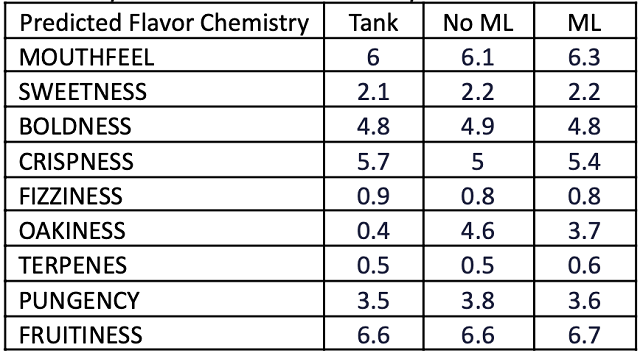

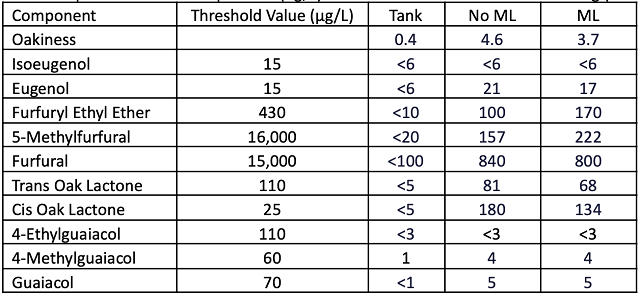

The wines received significantly different sensory scores for aromatic intensity, fruit intensity, and body/volume (Table 4). Scores for aromatic intensity and body/volume were higher for both of the barrel fermented wines relative to the tank fermented wine (Figure 3). Though fruit intensity scores were significantly different using repeated measures ANOVA, none of the treatments was significantly different from any of the others in side by side comparisons. Tastry uses measurement of aroma-active compounds, thresholds of detection and known interactions to predict sensory perception of the wine. The tank fermented wine was predicted to be perceived as crisper and less oaky than either of the barrel fermented wines (Table 5). The barrel fermented wine that received SO2 shortly after the completion of fermentation (no ML treatment) was predicted to have higher perception of oakiness than the wine that did not receive SO2 this early. These also had somewhat different values for odor active compounds associated with oak flavor (Table 6). These differences may be due to differences in barrels. Though barrels were from the same cooper and forest, barrels still show large amounts of variation, especially when new. This could also be due to oxidation during several months without SO2 addition in the “ML” treated wine.

Why was there no malolactic fermentation?

Despite inoculation, three barrels of Petit Manseng did not undergo malolactic fermentation. Malic acid bacteria are not as resilient as yeast. Overall, they are more sensitive to environmental conditions. They also have more complex nutrient needs, as they are much less able to synthesize amino acids needed to build proteins. A full accounting of inhibitors to malolactic fermentation is beyond the scope of this report, but following are several biotic and abiotic factors that limit growth and/or activity of lactic acid bacteria7,8:

-

pH less than 2.9-3.0 inhibits malolactic fermentation while a pH = 3.4 is considered most desirable.

-

Alcohol above 15% is inhibiting to most strains.

-

Temperatures that are too high (above 25°C) increase the toxicity of alcohol while those that are too low (less than 16°C) limit the multiplication and activity of bacteria. For wines with 12.5 – 14 % alcohol, 18-22°C is optimal.

-

An initial malic acid range of 2-4 g/L malic acid is most favorable. As the conversion progresses, increasing lactic acid levels become inhibitoryInitial lactic acid levels >0.3 g/L are inhibitory to starter cultures. Some yeast produce lactic acid, so this confounds yeast strain decisions.

-

Residual fungicidal sprays (for botrytis) are inhibiting.

-

Deficiency of oleic acid due to over clarifying can inhibit cell growth.

-

Yeast lees seem to be stimulatory because they release amino acids, detoxify polysaccharides, and absorb inhibitory compounds

When considering any of the above factors affecting the growth of lactic acid bacteria, it is important to realize that they work synergistically. A favorable level of one may offset the stressful effects of another. However, stress in one area diminishes tolerance in another area. Different strains of Oenococcus will have different sensitivities or tolerances to these factors. Using an inoculated strain allows the winemaker to match the range of tolerance with the anticipated environmental conditions.

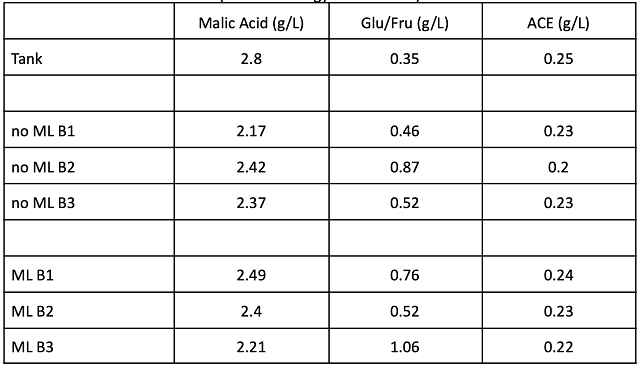

At Potomac Point, several of these environmental factors were well within range (Table 7). Care was taken to avoid using SO2 at crush to minimize free and total SO2. Lactoenos Standard is marketed as tolerant down to a pH of 2.9, which is a good choice overall for Petit Manseng. Malic and lactic acid levels are well within the published tolerance of this strain as well. However, these wines aged in a cold cellar that rarely got above 60°F (Hope Nastri, personal communication), which would be expected to slow the growth rate of Oenococcus. The alcohol content of this wine was also higher than 14%, the published limit for this bacteria (and most Oenococcus). These factors, taken together, may have been too inhibitory for this strain of Oenococcus to overcome.

References

(1) Wolf, T. K. Wine Grape Production Guide for Eastern North America; Plant and Life Sciences Publishing: Ithaca, New York, 2008.

(2) Wrapping Our Heads Around Petit Manseng. Tablas Creek Vineyard Blog. https://tablascreek.typepad.com/tablas/2016/03/wrapping-our-heads-around-petit-manseng.html (accessed 2018-12-14).

(3) Wood, V.; Custer, S.; Watson, K.; Chibbaro, B. Virginia 2017 Commercial Grape Report. VCU School of Business 13.

(4) Gardner, D. M.; Duncan, S. E.; Zoecklein, B. W. Aroma Characterization of Petit Manseng Wines Using Sensory Consensus Training, SPME GC-MS, and Electronic Nose Analysis. American Journal of Enology and Viticulture 2017, 68 (1), 112–119.

(5) Tominaga, T.; Baltenweck-Guyot, R.; Gachons, C. P. D.; Dubourdieu, D. Contribution of Volatile Thiols to the Aromas of White Wines Made From Several Vitis Vinifera Grape Varieties. Am J Enol Vitic. 2000, 51 (2), 178–181.

(6) Antalick, G.; Perello, M.-C.; Revel, G. de. Esters in Wines: New Insight through the Establishment of a Database of French Wines. Am J Enol Vitic. 2014, 65 (3), 293–304.

(7) Malolactic Fermentation: Importance of Wine Lactic Acid Bacteria in Winemaking; Morenzoni, R., Ed.; Lallemand Inc.: Montreal, 2015.

(8) Jackson, R. S. Wine Science: Principles and Applications, 4 edition.; Academic Press: Amsterdam, 2014.

Tables and Figures

Table 1: Juice Chemistry (VaTech Enology Services Lab)

*pH was taken from a frozen juice sample, and is likely higher than the actual value

Figure 1: Fermentation kinetics for three treatments of PM

Table 2: Wine chemistry post-alcoholic fermentation for three treatments of Petit Manseng (VaTech Enology Services Lab)

Table 3: Wine chemistry for three treatments of Petit Manseng. Glucose/Fructose (not shown) was <1g/L in each treatment. (ICV labs, January)

Figure 2: Optical density (color) for three treatments of PM

Table 4: Descriptive scores from blind sensory analysis of Petit Manseng

Figure 3: Comparative descriptive scores for three treatments of Petit Manseng

Table 5: Comparison of Tastry Predictive Flavor Chemistry for three treatments of Petit Manseng

Table 6: Comparison on oak components (ug/L) for three treatments of Petit Manseng (Tastry)

Table 7: Comparison of recommended conditions for malolactic fermentation and Peti Manseng wine chemistry. Recommended ranges were taken from the Scottlabs Fermentation Handbook.