Effect of fermentation temperature in barrel fermented Chardonnay (2021)

Lee Hartman

Bluestone Vineyards

Summary

Fermentation temperature is known to affect many aspects of the finished wine sensory profile. In barrel fermented white wines, winemakers can often affect the temperature of fermentation without extra costs or equipment simply by changing the location of the barrels. The purpose of this experiment was to explore differences in wine chemistry and sensory profiles with differences in fermentation temperature in barrel fermented Chardonnay. Warmer fermentations progressed more quickly than cooler fermentations, and produced slightly higher levels of acetic acid. There were no significant differences in sensory characteristics between the wines.

Introduction

Fermentation temperature is known to affect many aspects of the finished wine sensory profile. Temperature differences cause changes in gene expression for metabolic pathways, differences in cell membrane permeability, and differences in the overall pace of fermentation. Alcohol conversion is also sometimes affected by fermentation temperature.

Winemakers use a wide range of fermentation temperatures in aromatic white wines and temperature choice can be one element of achieving a given wine style. In 2017, Jim Law participated in a panel discussion at the VWA Technical Meeting during which he stated that he had recently changed his practice for barrel fermented Chardonnay. He used to ferment his Chardonnay at cool temperatures, but in recent years has moved to a warmer fermentation temperature in this variety. In 2018, Matthieu Finot from King Family Vineyards conducted a WRE trial comparing warm (72°F) and cool (60°F) fermentations of Chardonnay in two different yeast groups. In this trial, fermentation kinetics were predictably slower in cooler fermentations for both yeast strains, though there were also notable differences in fermentation kinetics for yeast strains at the same temperature. Cool fermentations had a small but significantly lower perception of body (F=4.18, p=0.05) with an average of 5.23 (SD=1.42) vs. 5.93 (SD=1.57) for the warmer fermentation with no significant differences for fruit intensity, floral intensity, or minerality. Unexpectedly, warmer fermentation wines had nearly 0.5% higher alcohol than the cooler fermentation. When a tasting panel of wine producers was presented with all four wines in randomly numbered glasses and asked to sort them into two groups of two, they were most likely to be sorted by temperature, indicating that temperature was more important than the yeast in determining sensory characteristics of the wine.

In barrel fermented white wines, winemakers can often affect the temperature of fermentation without extra costs or equipment simply by changing the location of the barrels. At Bluestone, Lee has the option to place his fermenting barrels in a very cool back cellar, in the main cellar, and outside in the shade of the crush pad. The purpose of this experiment was to explore differences in wine chemistry and sensory profiles with differences in fermentation temperature in barrel fermented Chardonnay. There were two treatments in this experiment:

-

“Warm” fermentation – fermentation was allowed to climb above 70°F without active cooling (in the main cellar or on the crush pad to get things warmed up)

-

“Cool” fermentation – fermentation was kept below 65°F by actively moving barrels to a cooler environment when the temperature began to rise

Methods

Wine was made according to the standard protocol of the winery. All operations and additions were made at the same stage of winemaking, at the same rate with the only difference being the ambient temperature.

Grapes were hand harvested and chilled overnight, then whole cluster pressed with the addition of 50 ppm SO2, 30 g/hl Glutastar, 5 g/hl FT Blanc, and 1.3 ml/hl Pec5L. Juice was cold settled in a temperature controlled stainless steel tank for 3 days, then racked to barrels for fermentation. Juice was inoculated with DV10 yeast. Fermaid O (20 g/hL) was added at 3°Brix depletion. Juice was chaptalized with 45 g/L sugar. Fermentation was monitored daily for sugar depletion and temperature. “Warm” barrels were moved outside onto a shaded crushpad during the day to increase temperature, then moved into the main cellar if the temperature exceeded 85°F. “Cool” barrels were kept in the back cellar.

Sensory analysis was completed by a panel of 32 wine producers. Due to restrictions put in place during COVID-19, sensory analysis was completed using shipped samples. Each wine producer received three wines in identical bottles, filled on the same day, each coded with random numbers. Two of the bottles contained the same wine while the third bottle contained the different wine. Participants were asked to identify which wine was different (a triangle test). There were four tasting groups with the unique wine in the triangle test balanced among the groups. Participants were then asked to score each wine on a scale of 0 to 10 for overall freshness, aromatic intensity, fruit intensity, fruit character, and body/volume. They were also given open ended questions to describe the wines. Results for the triangle test were analyzed using a one-tailed Z test. Descriptive scores were analyzed using repeated measures ANOVA.

Results

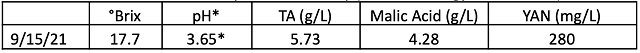

Juice chemistry is shown in Table 1. The juice sample was frozen prior to shipping to Virginia Tech, therefore the pH value is likely artificially high due to tartrate precipitation that occurred during shipping.

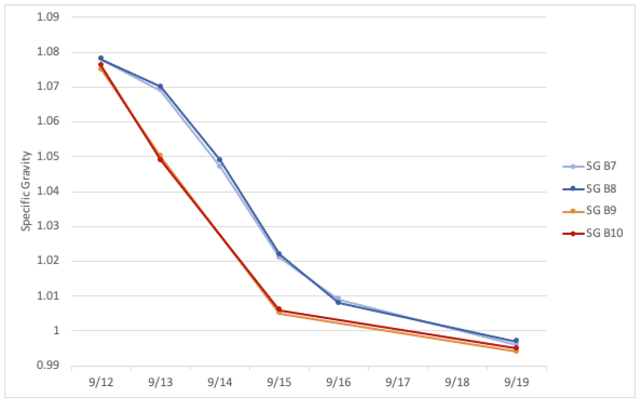

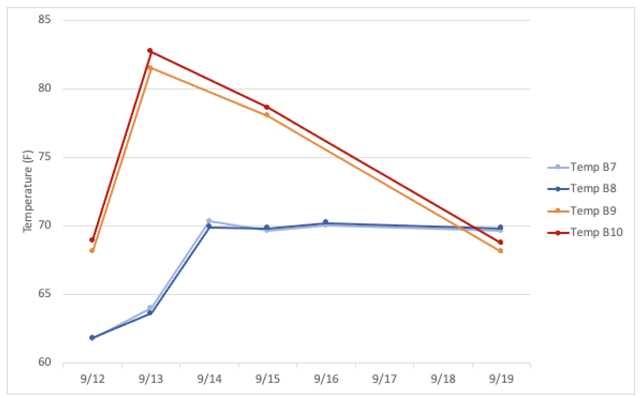

The “warm” fermentation had a very short lag phase and steeper fermentation curve, depleting most of the sugar in approximately 4 days (Figure 1). The cooler fermentation has a slightly longer lag phase followed by robust fermentation, completing the majority of fermentation in 6 days. The warmer fermentation peaked at 84°F early in the fermentation, corresponding with the end of log phase growth and maximum metabolism of the yeast (Figure 2). The cooler fermentation also experienced an increase in heat corresponding with the onset of stationary phase, but did not exceed 70°F, presumably due to ambient cooling. The overall heat accumulated by the “warm” fermentation far outpaced the overall heat experienced in the “cool” fermentation.

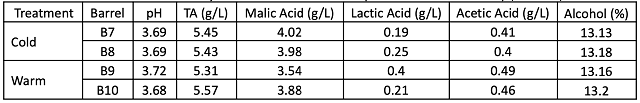

The finished wines had similar general chemistry (Table 2). Each of the wines underwent a small amount of malolactic conversion during fermentation, with B9 showing the most lactic acid, but this effect was not consistently different for different temperature regimes. Alcohol conversion rates were also not different between the wines. The warmer barrels had slightly higher volatile acidity than the cooler barrels, averaging 0.48 g/L compared to 0.42 g/L).

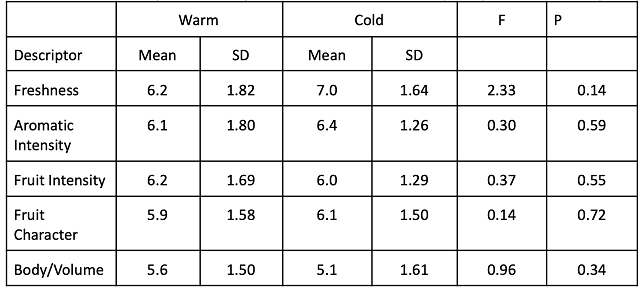

In a triangle test, 12 out of 32 respondents were able to distinguish which wine was different, indicating the wines were not significantly different (Z= 031, p= 0.38). There were no significant differences in scores for freshness, aromatic intensity, fruit intensity, fruit character or body/volume (Table 3).

Table 1: Juice chemistry for Chardonnay (VaTech Enology Services Lab)

* Juice was frozen for transport, likely affecting pH

Figure 1: Fermentation kinetics for two treatments of Chardonnay (in-house data). Blue lines indicate “cool” barrels while red/orange lines indicate “warm” barrels.

Figure 2: Temperature kinetics for two treatments of Chardonnay (in-house data). Blue lines indicate “cool” barrels while red/orange lines indicate “warm” barrels.

Table 2: Wine chemistry for two fermentation temperatures of Chardonnay (ICV labs)

Table 3: Statistical analysis for descriptive scores from blind sensory analysis of Chardonnay