Managing Rose Thiol Character with Fermentation Temperature (2017)

Matthieu Finot

King Family Vineyards

Summary

This study examined the impact of increasing fermentation temperature on the chemical, sensory, and thiol attributes of Merlot rose. Merlot grapes were harvested, destemmed, and cold soaked for 1 day, then pressed off into tank. Juice was stabulated in tank for 3-5 days before racking into two separate tanks. The NTU of the juice was adjusted to 200 prior to fermentation. All treatments between the juices and wines were equal, except that the control was fermented at 14°C for the whole fermentation whereas the treatment was fermented at 20°C for the first 4 days, then dropped to 14°C for the rest of fermentation. Wine chemistry was not much affected by the treatments. Hydrogen sulfide and 3-MH were slightly lower in the higher temperature fermentation. 71% of judges were able to distinguish the wines in triangle testing, suggesting a statistically significant difference between the wines (p<0.001). This may have been due to turbidity differences from lees being disrupted in the bottles during pouring. In general, the control wine was preferred. There were no strong trends for the descriptors used in this study. There was a slight tendency for Fruit Intensity, Thiol Aromas, and Overall Aromatic Intensity to be increased by Low Temperature. The High Temperature wine may have had slight reduction relative to the low temperature wine.

Introduction

Fermentation temperature impacts the volatile compounds produced during fermentation. Generally, higher concentrations of esters are found in wines produced at lower fermentation temperatures, likely due to lower volatilization and decreased chemical breakdown of the esters (Killian and Ough 1979; Boulton et al. 1996; Molina et al. 2007), but this is not always the case (Molina et al. 2007). Fermentation temperature also impacts the biochemical pathways of the cell, which can influence aroma development (Torija et al. 2003; Molina et al. 2007). Many volatile compounds seem to be produced during the exponential growth phase except for acetate esters, produced mostly during the stationary phase (Molina et al. 2007). Additionally, different kinds of volatile compounds are favored at different temperatures, with one study showing that more “flowery” components were favored at 28°C whereas more fresh and fruity components were favored at 15°C (Molina et al. 2007). Volatile thiols can also be impacted by fermentation temperature. One study found that 3-mercaptohexanol (3-MH) and 3-mercaptohexyl acetate (3-MHA) were increased in Sauvignon blanc wines produced at 20°C over 13°C (Masneuf-Pomarède et al. 2006). Due to the impact of yeast growing phase and temperature on these products, and the effect of higher temperature on the potential volatilization and chemical degradation of esters, it is hypothesized that fermenting juice at a higher temperature during growth phase followed by cooling the juice to lower temperatures may allow for increased thiol production and also increased volatile retention. This study examines the impact of this kind of winemaking practice on Merlot rose wine production.

Results and Discussion

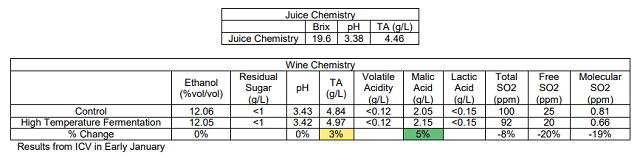

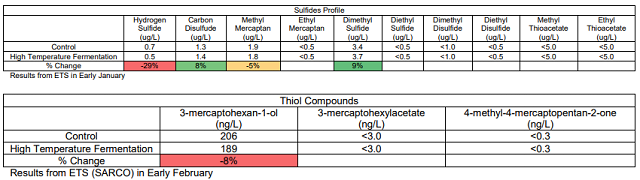

There were no major differences in wine chemistry in this study. Hydrogen sulfide and 3-MH were slightly lower in the higher temperature fermentation.

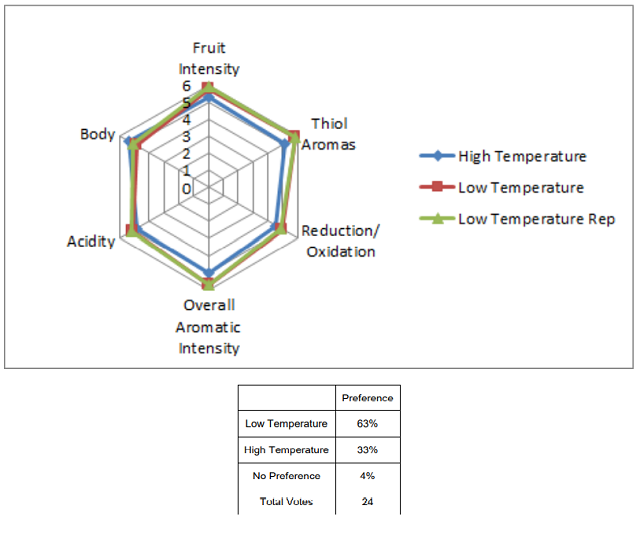

For the triangle test, of 34 people who answered, 24 people chose the correct wine (71%), showing a statistically significant difference between wines (p<0.001). There were turbidity differences between the wines (due to pouring bottles with lees being more prominent in both treatments towards the end of pouring), which may have impacted the triangle test. These wines were voted to have an average degree difference of 5.6 (out of 10), suggesting that the wines were moderately different. In general, people who answered correctly preferred the low temperature fermentation. For the descriptive analysis, there were no strong trends for the descriptors used in this study. There was a slight tendency for Fruit Intensity, Thiol Aromas, and Overall Aromatic Intensity to be increased by Low Temperature. The High Temperature wine may have had slight reduction relative to the low temperature wine.

These results suggest that fermenting at higher temperature during growth phase and then cooling the juice did not help with volatile retention, although the numerical amounts of the thiol and sulfide compounds were not very different between treatments. The low temperature fermentation was generally preferred due to a more preferable and intense aroma profile. It cannot be determined from this study whether a higher concentration of volatiles were produced in one treatment over the other, or if instead retention was merely affected by one treatment over the other, as this would require the stable capture of volatile components produced throughout fermentation. Thus this study is inconclusive and should be repeated multiple times, as well as with different grape varieties (especially aromatic grape varieties). More work should be done on the ester profile as well. Finally, a treatment which ferments the must at a high temperature throughout fermentation should be added as well, as an additional control.

Methods

Merlot grapes were harvested and destemmed around August 26, 2017 and received 1 day of skin contact. Must was pressed the following day and was stabulated for 3-5 days before being split into two tanks on August 30. The NTU of the juice was adjusted to 200 prior to fermentation. All treatments between the juices and wines were equal, except that the control was fermented at 14°C for the whole fermentation whereas the treatment was fermented at 20°C for the first 4 days, then dropped to 14°C for the rest of fermentation. On August 31, both juices were inoculated with Viniferm Revelation at 20g/hL, with 50mL Lafazyme Thiol added to each treatment. On September 4, 30g/hL Fresharom and 15g/hL Fermaid K were added to the fermentations. On September 5, 40g/hL bentonite and 20g/hL casein were added to the fermentations. On September 23 both fermentations were stabilized with 50ppm sulfur dioxide. Both wines received 0.5g/L tartaric acid on October 19.

These wines were tasted on January 31, 2018. For the triangle test, descriptive analysis, and preference analysis, anybody who did not answer the form were removed from consideration for both triangle, degree of difference, and preference. Additionally, anybody who answered the triangle test incorrectly were removed from consideration for degree of difference and preference. Additionally, any data points for preference which did not make sense (such as a person ranking a wine and its replicate at most and least preferred, when they correctly guessed the odd wine) were removed.

In order to balance the data set to perform statistical analysis for descriptive analysis, any judge who had not fully completed the descriptive analysis ratings were removed. In order to then make the number of judges between groups equivalent, two judges from group 3 were transferred to group 1, and another judge from groups 2 and 3 were eliminated. This resulted in a final data set of 3 groups, each with 7 judges (considered as replications within groups, and groups were considered as assessors). Data was analyzed using Panel Check V1.4.2. Because this is not a truly statistical set-up, any results which are found to be statistically significant (p<0.05) will be denoted as a “strong trend” or a “strong tendency,” as opposed to general trends or tendencies. The statistical significance here will ignore any other significant effects or interactions which may confound the results (such as a statistically significant interaction of Judge x Wine confounding a significant result from Wine alone). The descriptors used in this study were Fruit Intensity, Thiol (grapefruit, boxwood, passionfruit, guava, etc), Reduction/ Oxidation, Overall Aromatic Intensity, Acidity, and Body.

References

Boulton, R., Singleton, V., Bisson, L., and Kunkee, R. 1996. Principles and practices of winemaking. Chapman & Hall, New York.

Killian, E. and Ough, C.S. 1979. Fermentation esters–formation and retention as affected by fermentation temperature. Am. J. Enol. Vitic. 30:301–305

Masneuf-Pomarède, I., Mansour, C., Murat, M.-L., Tominaga, T., and Dubourdieu, D. 2006. Influence of fermentation temperature on volatile thiols concentrations in Sauvignon blanc wines. International Journal of Food Microbiology. 108: 385-390.

Molina, A.M., Swiegers, J.H., Varela, C., Pretorius, I.S., and Agosin, E. 2007. Influence of wine fermentation temperature on the synthesis of yeast-derived volatile aroma compounds. Appl. Microbiol. Biotechnol. 77: 675-687.

Torija, M.J., Beltran, G., Novo, M., Poblet, M., Guillamón, J.M., Mas, A., and Rozès, N. 2003. Effects of fermentation temperature and Saccharomyces species on the cell fatty acid composition and presence of volatile compounds in wine. Int. J. Food Microbiol. 85: 127–136