Does cold stabilization of red wine press fraction reduce K+ and stabilize pH during aging? (2020)

Matthieu Finot and Yordanos Gebru

King Family Vineyards

Summary

Petit Verdot has several characteristics in the vineyard that are a good fit to produce consistently high quality, distinctive wines in Virginia. However, in the winery, Petit Verdot often finishes fermentation with pH values above 4.0, leading to potential for microbial spoilage during long aging in the cellar. The likely cause of high pH in finished Petit Verdot is excess potassium, which may be removable using cold stabilization. In this set of experiments, two lots of Petit Verdot were cold stabilized with KHT seeding post-fermentation. For one lot, the press fraction was separated from free run, acidulated to pH<3.6, cold stabilized, then blended with the free run. A control lot was acidulated but not cold stabilized. There were no differences potassium or pH between control and treatment lots post-stabilization, indicating that cold treatment did not remove more potassium than tartaric acid addition alone. In a second experiment, Petit Verdot wine (free run + press fraction) was split into control and treatment. The treated wine was subjected to post-fermentation cold stabilization without prior acidulation. Once again, there were no differences in potassium or pH between control and treatment wines post stabilization. These results indicate that cold stabilization with KHT seeding is not an effective strategy to remove potassium from fermented red wine.

Introduction

Petit Verdot is a native wine grape variety from Southern France, and a minor component of Bordeaux blends1,2, but often takes center stage in Virginia3. It is the third most common red variety grown in Virginia4, bottled both as a varietal wine and also as a notable contributor to Meritage blends. Petit Verdot provides power, color, tannin, and perception of ripeness, and often fills the same space on the tasting bar as Cabernet Sauvignon in other regions3. In the vineyard, Petit Verdot has small berries and loose clusters, allowing it to fully ripen with less rot in our humid climate.1 However, in the winery, Petit Verdot often finishes fermentation with pH values above 4.0, leading to potential for microbial spoilage during long aging in the cellar.

The likely cause of high pH in finished Petit Verdot is excess potassium in the grapes. Throughout fermentation, potassium is released from skins and complexes with tartaric acid to form potassium bitartrate (KHT). When in excess, KHT can form crystals and precipitate, leaving the finished wine with high pH and low acidity. Excess potassium can also limit the effectiveness of tartaric acid additions. Common solutions to making red wine with high potassium fruit involve large, early additions of tartaric acid5, essentially a form of potassium fining. However, tartaric acid is expensive, and high acid addition can have sensory consequences.

Potassium can also be removed by cation exchange. Equipment companies have developed this technology into machinery capable of running several thousand liters of wine per hour, however, these machines are costly ($30,00-40,000) and beyond the reach of most small wineries.

Another alternative is the removal of potassium through tartrate stabilization, followed by tartaric addition at lower rate and higher return. At King Family, press fraction and free run Petit Verdot wines are combined after pressing, then acidulated before aging. In a preliminary study in 2019, cold stabilization alone appeared to stabilize the pH and enhance the effect of acid addition in the cold stabilized wine. In the present study, two separate lots of Petit Verdot were treated with different approaches to cold stabilization. For each, a control was included with no cold stabilization. For PVB, the press fraction wine was cold stabilized prior to recombination and aging. This allowed for acidulation of the press fraction to pH<3.6 prior to cold stabilizaiton. However, many wineries in Virginia do not produce large enough lots of wine to separate and cold stabilize the press fraction alone. To test if cold stabilization of the whole lot was a viable alternative, the free run and press fraction wines were re-combined then cold stabilized prior to aging in PVTV.

Methods

Petit Verdot wine was made according to the standard protocol of the winery. Grapes were hand harvested and refrigerated overnight. The following day, grapes were sorted then destemmed to temperature-controlled fermentation tanks. At processing, grapes were treated with 12 g/hL Stab Micro M and 24 mg/L SO2 along with 300 g/hL mini chips Bois Frais. Must was inoculated the next day with 15 g/hL D254 yeast and chaptalized (40 g/L for the B block, 25 g/L for the TV block). Lafase HE Grand Cru was also added at this time (4 g/hL). Cap management (pumpovers) occurred twice per day. At pressing, the press fraction was kept separate from the free run.

Block B (Figures 1 & 2)

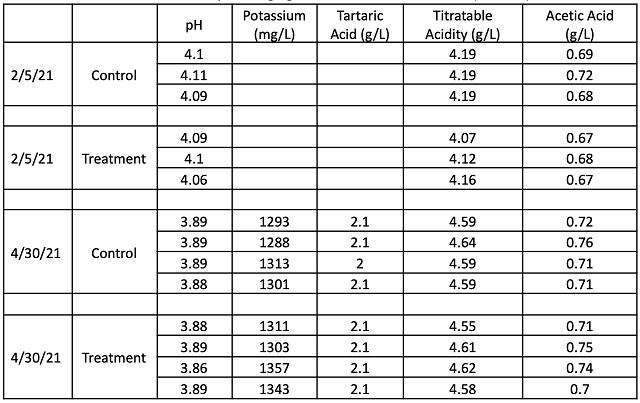

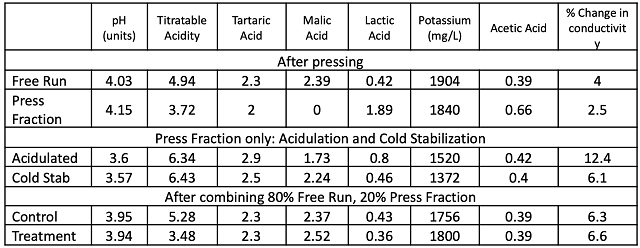

After allowing a day for settling, both free run and press fraction tanks were split into two tanks. An acid trial was done on the press fraction wine to determine the rate of tartaric acid addition needed to achieve a target pH less than 3.6. Though this is a larger addition than would be acceptable for a larger lot of wine, acidulation to this pH shifted the equilibrium in solution so that when bitartrate precipitated out of solution, it was replaced from the tartaric acid portion of the equilibrium rather than the tartrate anion portion. Press fraction was acidulated with 2.6 g/L tartaric acid to achieve a pH=3.6. Based on the proportional volume, this amounts to a 0.6 g/L addition to the whole lot once recombined.

For the control lot, free run and press fraction were combined (80% free run, 20% press fraction) and racked to barrels for malolactic fermentation. The remaining press fraction was cold stabilized with seeding (4 g/L cream of tartar) and agitation according to Zoecklein et al (1995, p237-238)(Figure 2)8. Conductivity and potassium levels were measured for free run and press fraction, before and after cold stabilization. Cold stabilized press fraction was racked off tartrate crystals when cold. After cold stabilization, this press fraction was combined with free run wine at the same proportion as control and transferred to barrels for aging.

After completion of malolactic fermentation, all barrels (control and treatment) received 66ppm SO2 and 3 g/hL Stab Micro (Enartis). Based on final wine pH, 1 g/L tartaric acid was added at the completion of malolactic fermentation with an additional 0.5 g/L added in February.

Block TV (Figure 2)

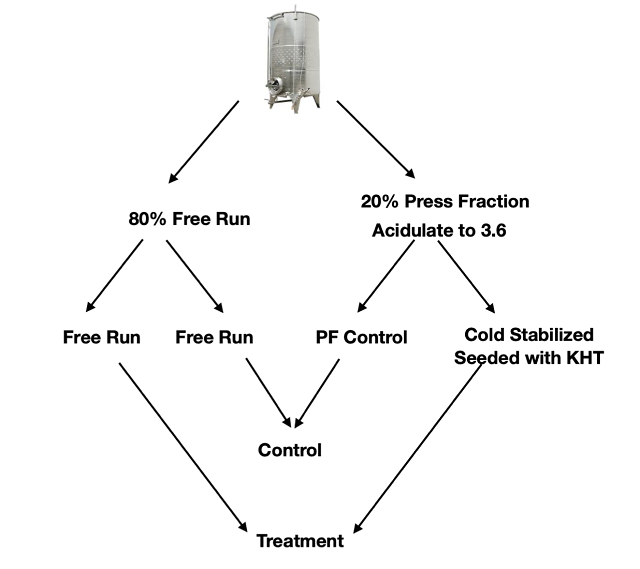

After pressing, free run and press fraction wines were combined. A portion was transferred to barrel soon after settling. A second portion was cold stabilized with seeding prior to transfer to barrel. This approach tested the efficacy of removing potassium by cold stabilization for smaller batches of wine where the press fraction alone would be too small for effective cold stabilization. SO2 and Stab Micro were added after the completion of malolactic fermentation confirmed by enzymatic analysis. At the completion of malolactic fermentation, 1 g/L tartaric acid was added to all barrels.

Results

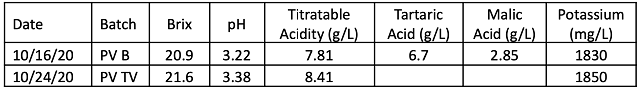

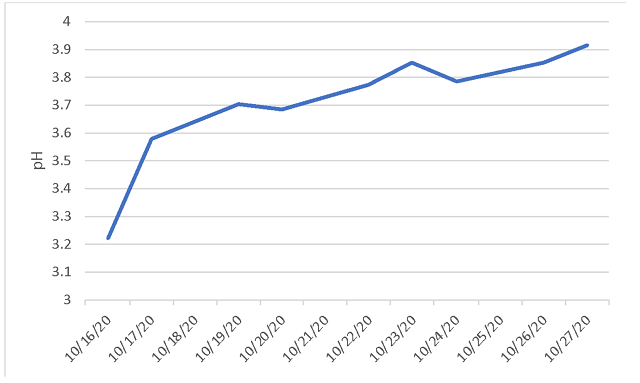

Petit Verdot from block B was harvested with a pH of 3.22, well within a range that would be considered healthy for red wine fermentation. However, it also showed a potassium level of 1800 mg/L, considered very high, with the potential to result in high pH wine5–7. There was a very rapid increase in pH in the first few days of fermentation (Figure 4), presumably due to extraction of potassium from skins. Much of the potassium in the grape berry is concentrated in the skins, with levels up to 9000 mg/L reported in Australia Shiraz7. This rapid increase is consistent with increases also seen in previous experiments using cold soak, indicating simple skin contact is sufficient for extraction, even before microbial activity or ethanol extraction. pH continued to increase throughout fermentation, with wine measuring a pH near 4.0 at the completion of alcoholic fermentation (Table 2).

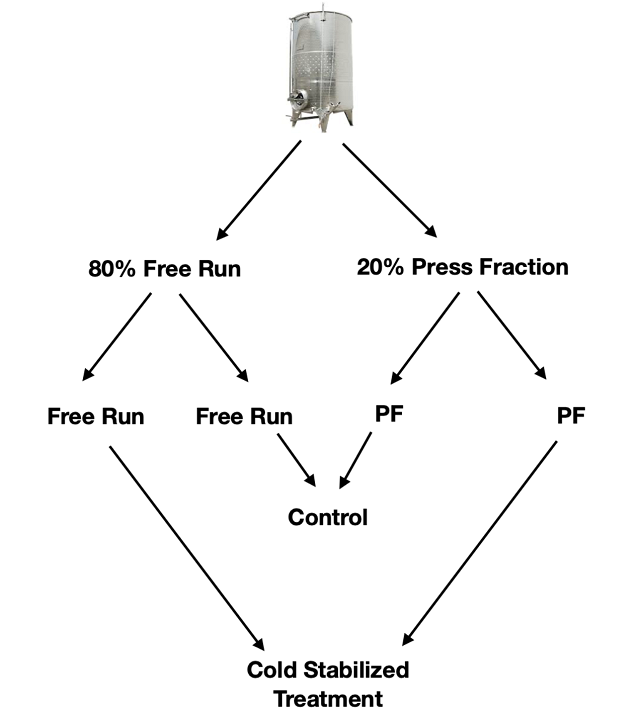

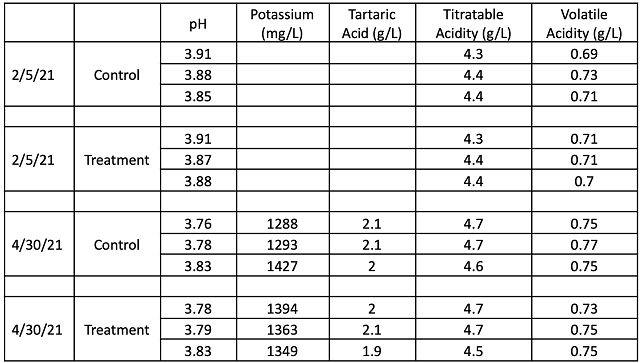

Acidulation of the press fraction appeared to have a fining effect on potassium (Table 2) with potassium levels dropping from 1830 mg/L to 1520 mg/L simply with acid addition, prior to cold stabilization. Cold stabilization itself further decreased the potassium levels to 1372 mg/L, however this shift in potassium was not sufficient to shift the pH. When cold stabilized press fraction was recombined with free run wine, there were no discernable differences in pH, tartaric acid, or titratable acidity between control and treatment wines. There were also no differences in acid chemistry through aging, with each lot showing the same response to subsequent tartaric acid additions. In both lots, there was a decrease in potassium from November through April, presumably due to potassium bitartrate precipitation. Both lots were shown to be tartrate unstable at the time of combination in November (Table 2). Tartaric acid measured 2.3 g/L in both lots in November, 1 g/L was added at that time, with 0.5 g/L added in February. If all tartaric acid was retained, 3.8 g/L tartaric acid should be present in April. Instead, each lot has only 2 g/L, indicating tartaric acid additions are again fining out potassium rather than contributing to the acidity of the wine. Unfortunately cold stabilization of the press fraction alone was insufficient to prevent loss during aging.

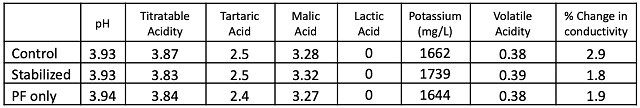

Petit Verdot from block TV was harvested with a pH of 3.38, again well within an acceptable range for red fruit, but very high potassium (1850 mg/L), leading to high pH (3.93) by the end of primary fermentation (Table 4). Some potassium was lost during fermentation, with 1600-1700 mg/L remaining at the beginning of malolactic fermentation (Table 4). Cold stabilization of the treatment lot did not alter the pH or potassium of the wine. When stability was measured using the Davis conductivity test, both the control and treatment (seeded with 4 g/L cream of tartar) were considered stable. Though these wines have a high amount of potassium, they have relatively low tartaric acid and likely have several other stabilizing molecules. During aging, both wines again lost potassium, likely due to precipitation of added tartaric acid. The wine finished fermentation with 2.5 g/L tartaric acid, to which 1 g/L was added in February. By April, both lots had 500 mg/L less potassium and only 2.1 g/L tartaric acid. Both lots showed the same acid profiles after treatment and aging, so fast cold stabilization of the wine was not an effective treatment for removing potassium and retaining tartaric acid additions. Large tartaric acid additions alone had more effect on removing potassium than cold stabilization.

References

(1) Wolf, T. K. Wine Grape Production Guide for Eastern North America; Plant and Life Sciences Publishing: Ithaca, New York, 2008.

(2) Robinson, J. The Oxford Companion to Wine, Third Edition.; Oxford University Press: Oxford, 2006.

(3) Carrie, D. Two Unsung Grapes Putting Virginia Wine on the Map. Wine Enthusiast. 2018.

(4) SMS Research Advisors. 2019 Virginia Commercial Grape Report. 2020.

(5) Gardner, D. Making (Red) Wine from Fruit High in Potassium. Penn State Extension Wine & Grapes U., 2016.

(6) Berg, H. W.; Akiyoshi, M.; Amerine, M. A. Potassium and sodium content of California Wines. 3.

(7) Ask the AWRI: Winemaking with High PH, High TA and High Potassium Fruit. Grapegrower and Winemaker 2018, October (657).

(8) Zoecklein, B. Protein Stability Determination in Juice and Wine. Virginia Tech Online Enology Publications 1991.

Figure 1: Treatment scheme for PV B block

Figure 2: Cold stabilization of small lot of Petit Verdot press fraction

Figure 3: Treatment Scheme for PV TV Block

Table 1: Juice chemistry for two lots of Petit Verdot (In house labs, ETS labs)

Figure 4: pH values during fermentation for PV Block B (in-house data)

Table 2: Chemistry for PVB after completion of alcoholic fermentation (ICV labs). All values are reported in g/L unless otherwise noted

Table 3: Chemistry after aging for two treatments of PV B (ICV Labs)

Table 4: Chemistry for PV TV after completion of alcoholic fermentation and cold stabilization (ICV labs). All values are reported in g/L unless otherwise noted.

Table 5: Chemistry after aging for two treatments of PV TV (ICV labs)