The Impact of Agrothermal Systems Heat Blast Treatments in Cabernet Sauvignon

Benoit Pineau and Preston Thomas

Stone Tower Winery

Summary

Agrothermal Systems heat blast treatment is marketed to reduce the need for fungicide, controls pests, increase yields and improve wine quality by increasing phenols and antioxidants. This treatment relies on a transient dose of heat from a system pulled behind a tractor through the vineyard rows. The following study aims to measure the effects of heat blast treatment in Virginia Cabernet Sauvignon. A single block of Cabernet Sauvignon was divided to receive no heat blast vs. 10-12 treatments during the growing season. There were no significant differences in cluster weight, berries per cluster, or berry weight between treatments. The control grapes were slightly riper with higher Brix and pH and had much higher levels of quercetin glycosides, total anthocyanins, and moderately higher levels of tannin. Control wines had slightly higher color intensity, and higher anthocyanins while heat blast wines had higher tannins. The wines were found to be significantly different in a triangle test, with control wine scoring significantly higher for aromatic intensity.

Introduction

In its promotional material, Agrothermal Systems claims its heat blast treatment reduces the need for fungicide, controls pests, increases yields and improves wine quality by increasing phenols and antioxidants1. If true, this intervention could be a valuable tool in Virginia’s humid climate. However, Dr. Tony Wolf, Professor of Viticulture and Director of the Virginia Tech Agriculture and Research Center, cautions that though “there is some physiologic precedent for the ‘heat-shock’ treatment” including expression of systemic acquired resistance (SAR) genes and related metabolites” the question remains if the detection of metabolites in grapes in lab studies translates to a treatment that alters fruit quality and wine quality within reasonable economic parameters (personal communication).

Heat blast treatment uses “a gas-operated, hydraulic fan heater system that generates a 300°F hot air stream through the plant.”1 The heater is pulled behind a tractor at 3-4 mph and aims the hot air stream at the fruit zone. A video of the machine in action is posted on the website of the manufacturer1. In practice, heat is applied 10-12 times between bloom and harvest according to a proprietary schedule. When asked, two Virginia winemakers, Shai Van Gelder (Barrel Oak Winery) and Preston Thomas (Stone Tower Winery) estimated that, at a speed of 3-5 mph, treatment time ranges from 1-2.5 hours per acre depending on row spacing and length (personal communication). In a study conducted in Washington State, Gohil and Moyer, 2014)2 found that at a tractor speed of 4 mph, heat blasted vines were exposed to hot air for 1.5 to 2 sec each, resulting in increased grape temperature of 10-20 °F for 10-20 seconds. Grapes returned to initial temperature within 60 seconds. This study found no significant differences in fruit set, timing of veraison, pH, TA, or Brix in either Merlot or Syrah.

The Agrothermal Systems website and internal documents indicate that cellular responses to “instantaneous heat shock” induced by heat blast treatment “activate the plant self-defense system and increase its production of phenol and antioxidants – the main flavonoids in wine. The resulting wine exhibits enhanced flavor profiles, increased aromatic definition, and smoother texture.”1 Other studies of short term heat shock3,4 indicate that heat shock in general shifts gene expression away from ripening (sugar accumulation, production of phenolics) to the production of heat shock proteins, thus delaying or even inhibiting maturation. In addition, the changes in heat seen with early morning heat blast are less than would be expected for grapes during the heat of an average day.2

All previously published field work has been done in dry climate areas (California and Eastern Washington). In a WRE trial conducted in 2018 at Barrel Oak Winery in Delaplane, Virginia, a single block of Petit Manseng was split into treated and untreated subplots5. There were no obvious differences in fruit sampling parameters in replicate plots (berry weight, Brix, pH, TA). At harvest, control fruit had higher Brix and pH while heat blast treated grapes were harvested with higher levels of tannin. In a blind triangle test, wines produced from these grapes were perceived as different, with the treatment wine receiving higher descriptive scores for bitterness. No objective measurement of disease incidence or yield parameters were done in the Petit Manseng study. The following study aims to measure the effects of heat blast treatment in Virginia Cabernet Sauvignon.

Methods

A single block of Cabernet Sauvignon in VSP trellising was divided into two sections with similar topology. Both sections were farmed identically with regard to hedging, leaf pulling, sucker removal, foliar nutrients, cluster exposure and netting. Both control and treatment blocks had identical chemical spray regimes.

The treatment block received heat blast to the canopy and fruiting zones using a proprietary protocol set forth by the manufacturer. Treatments were applied during bloom, veraison, and ripening, and varied in frequency depending on vine physiology and weather events. There were approximately 10-12 treatments for each treatment block. Treatments started pre-dawn in order to finish the application before ambient temperatures reached 80-85°Fahrenheit. The propane tank is 60 gallons and could theoretically make applications to 20 acres of vines in one tank, however usage was variable and depended heavily on ambient temperature (lower ambient temperatures require more heat to reach the desire application temperature). The applications were done at 3 miles per hour, which translated to 2.5 hours per acre for blocks at 7 foot spacing.

Grapes were harvested separately on the same day, chilled overnight then destemmed and optically sorted into Tbins with the addition of 50 ppm SO2, 4 g/100 kg Grand Cru, and untreated oak beans. Tbins were inoculated with 25 g/hL Premier Cru yeast. Fermentations were carried out in a 30°C ambient environment, punched down twice daily and monitored daily for density and temperature. Opti-red (20 g/hL) and sugar (4.5 kg/bin) were added at the end of lag phase; 0.5 g/L tartaric acid was added to the must two days before pressing. Wine in these bins completed malolactic fermentation with ambient bacteria during alcoholic fermentation. Wine was pressed at the completion of alcoholic fermentation (when specific gravity reached 0.995), wine was settled then transferred to barrel. As malolactic conversion was already complete, 50 ppm SO2 was added at barrel down. Free SO2 was monitored monthly with additions to a target of 30ppm.

Sensory analysis was completed by a panel of 29 wine producers. Wines were presented blind in randomly numbered glasses. Tasters were presented with three wines, two of one type and one of another, and asked to identify which wine was different (a triangle test). There were three tasting groups with the unique wine in the triangle test balanced between groups. Tasters were then asked to score each wine on a scale of 0 to 10 for aromatic intensity, herbaceous/green character, fruit intensity, and structure (astringency). They were also given open ended questions to describe the wines. Results for the triangle test were analyzed using a one-tailed Z test. Descriptive scores were analyzed using repeated measures ANOVA.

Results

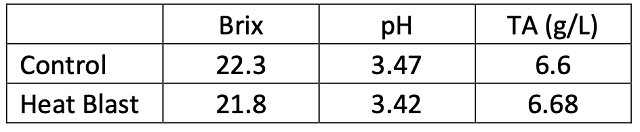

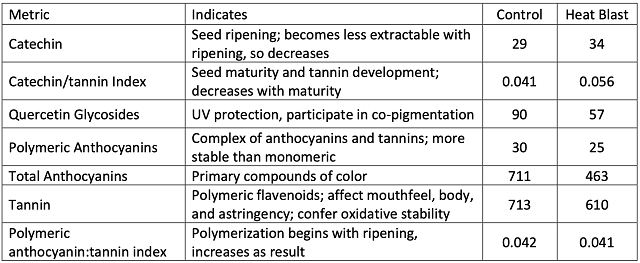

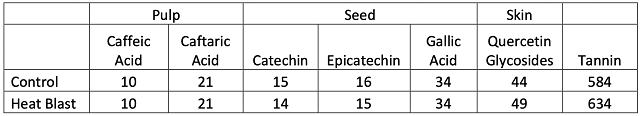

There were no significant differences in cluster weight, berries per cluster, or berry weight between treatments (Figure 1). Juice chemistry was nearly the same for both lots (Table 1). The control grapes were slightly riper with higher Brix and pH. Control grapes had much higher levels of quercetin glycosides, total anthocyanins, and moderately higher levels of tannin (Table 2). This led to a lower catechin:tannin index.

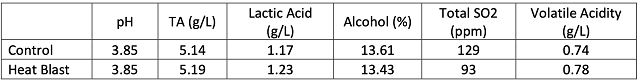

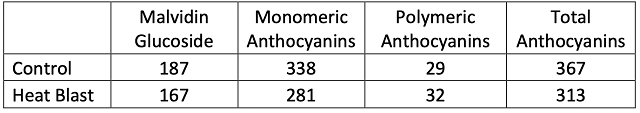

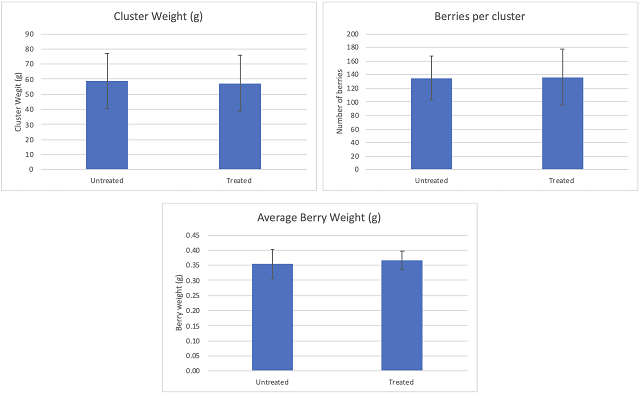

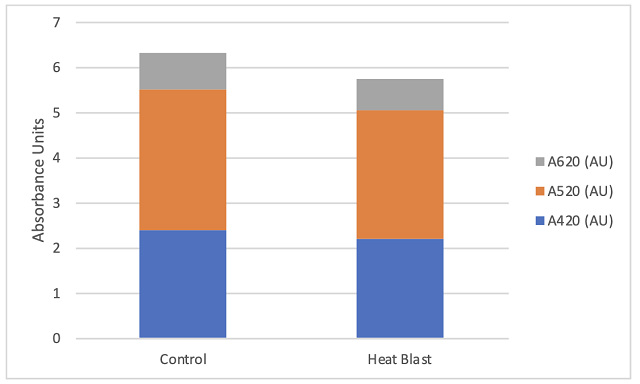

Fermentation was robust for both lots, with the control fermenting slightly faster than the heat blast. Thermal conditions were also similar (Figure 2). General wine chemistry was largely the same for both lots (Table 3). As would be predicted by grape anthocyanins, the control wines had slightly higher color intensity (Figure 3), and higher anthocyanins (Table 4). Other phenolics in the finished wines were very similar, with the heat blast wine having slightly higher tannin (Table 5). This is the opposite of what would be predicted from grape samples, however extraction and fermentation may have had an effect.

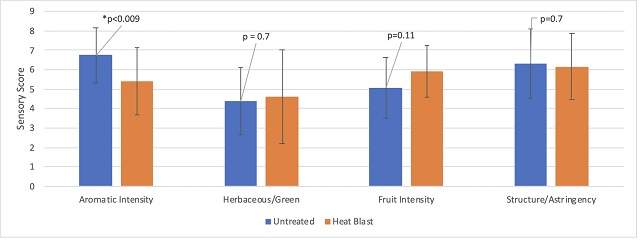

In a triangle test of control vs. heat blast wines, out of 18 respondents were able to distinguish which wine was different, indicating the wines were significantly different (Z=3.086, p= 0.001). The untreated grapes produced a wine with significantly higher aromatic intensity (F=7.7, p=0.009). There were no other significant differences among descriptors.

Table 1: Juice chemistry at harvest for two treatments of Cabernet Sauvignon (in-house data)

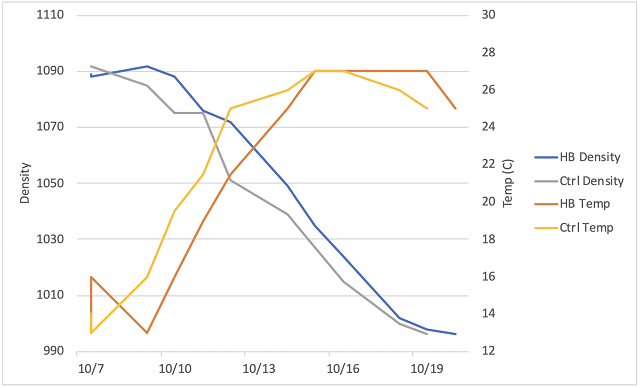

Table 2: Grape phenolics for two treatments of Cabernet Sauvignon (mg/L) (ETS Labs)

Table 3: General wine chemistry for two treatments of Cabernet Sauvignon (ICV Labs)

Table 4: Anthocyanins in two treatments of Cabernet Sauvignon (mg/L) (ETS labs)

Table 5: Phenolics in two treatments of Cabernet Sauvignon (mg/L)(ETS labs)

Figure 1: Fruit metrics at fruit set for two treatments of Cabernet Sauvignon (in-house data)

Figure 2: Fermentation Kinetics for two treatments of Cabernet Sauvignon (in-house data)

Figure 3: Color Intensity for two treatments of Cabernet Sauvignon (ICV labs)

Figure 4: Sensory scores for two treatments of Cabernet Sauvignon (WRE)

References

(1) Agrothermal Systems Case Studies. https://agrothermalsystems.com/case-studies/

(2) Gohil, H.; Moyer, M. Evaluation of Transient, in-Season Applied Heat to “Merlot” and “Syrah” Wine Grapes in Eastern Washington. HortTechnology 2014, 24 (6), 736 – 742.

(3) Reinth, M.; Torregrossa, L.; Luchaire, N.; Chatbanyong, R.; Lecourieux, D.; Kelly, M.; Romieu, C. Day and Night Heat Stress Trigger Different Trascriptomic Responses in Green and Ripening Grapevine (Vitis Vinifera) Fruit. BMC Plant Biology 2014, 14.

(4) Carbonnel-Bejerano, P.; Santa Maria, E.; Torres-Perez, R.; Royo, C.; Lijavetzky, D.; Bravo, G.; Aguirreolea, J.; Sanchez-Diaz, M.; Antolin, M. C.; Martinez-Zaptar, J. M. Thermotolerance Responses in Ripening Berries of Vitis Vinifera L. Cv. Muscat Hamburg. Plant and Cell Physiology 2013, 54 (7), 1200–1216.

(5) Ting, J. The Impact of Repeated Years of Agrothermal Systems Heat Blast Treatments on Grape Ripening, Wine Chemistry, and Wine Quality in Petit Manseng (2018). Winemakers Research Exchange, 2019. http://www.winemakersresearchexchange.com