The Impact of Agrothermal Systems Heat Blast Treatments on Grape Ripening, Wine Chemistry, and Wine Quality in Virginia (2017)

Shai Van Gelder

Barrel Oak Winery

Summary

The aim of this experiment was to determine measurable differences of grape quality by utilizing Heat Blast technology used to treat wine grapes. A block of Petit Manseng was divided into two separate sections. One section was treated with heat blast delivery to the canopy and fruiting zones using an Agrothermal Systems XT heat system. The other section was not treated with this technology. The treatment block was treated 1 to 4 times per month depending on stage of growth, with the treatment regime starting around veraison. The majority of treatments were near veraison. Chemical spray regimes were the same between treatments. All other vineyard and winemaking treatments between grapes were equal. Acidity and potassium was slightly lower in the heat-treated grapes. Quercetin and tannin slightly increased in grapes, whereas catechin slightly decreased. Wine chemistry was not very much affected except for lower malic acid levels in the heat treatment. The tannin content of wine with heat treatment was slightly higher for most compounds. Overall, these wines were not found to be significantly different. There was a very slight tendency for the Control to have higher Tropical Fruit intensity, Fruit Intensity, and Body. No major preference trends could be seen between wines. In the future, more studies should be performed with Agrothermal heat treatment and its impacts on fruit chemistry. These studies should look into multiple grape varieties, as well as closely monitor disease progression. The use of Agrothermal heat treatment in conjunction with different vineyard spray regimes should be investigated as well. Although more studies are needed to confirm this, these preliminary results suggest that heat treatment may be a beneficial tool for East Coast viticulture.

Introduction

Heat treatment technology is a recent viticultural development, which may have potential to reduce the incidence of fungal infections of the vine and thus reduce the amount of vineyard sprays needed during the growing season. Agrothermal Systems provides a tractor-pulled heat blast system which can be used to expose vineyard canopies to hot air. These treatments are marketed to potentially be able to reduce fungicide use by 50%, increase fruit set by and average of 24%, and increase harvest yield by an average of 20%. It is also marketed to increase the production of certain phenolic compounds and may reduce the impact of certain insect pests such as mites (Agrothermal Systems 2018). The goal of this study was to investigate the impact of this technology on ripening and wine quality in Petit Manseng.

Results and Discussion

There were not much qualitative differences in the canopy or fruit during ripening, but the treatment Petit Manseng appeared to have less sunburn. In other segments of the vineyard (not related to this study), the heat treatment appeared to effectively reduce mite pressure, although more work is needed to confirm this. Disease pressure was not monitored.

Acidity and potassium was slightly lower in the heat-treated grapes. This may suggest that some increased respiration took place in the heat treatment. Quercetin and tannin slightly increased in grapes, whereas catechin slightly decreased. Wine chemistry was not very much affected, except for lower malic acid levels. The tannin content of wine with heat treatment was slightly higher for most compounds.

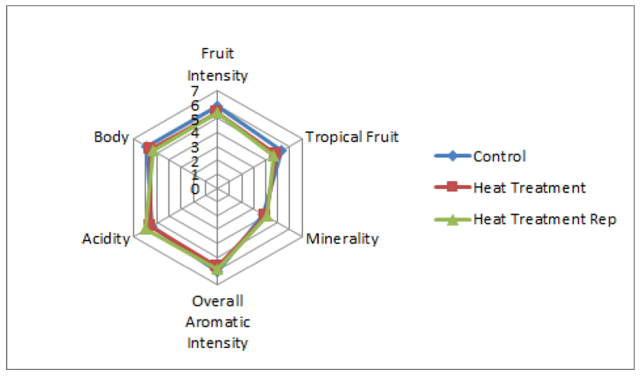

For the triangle test on February 7, of 24 people who answered, 8 people chose the correct wine (33%), suggesting the wines were not significantly different. People who answered correctly preferred the Heat Treatment to the control (4 judges preferred the heat treatment, compared to 2 for the control). This preference is weak. For the descriptive analysis, there were no strong trends for the descriptors used in this study. There was a very slight tendency for the Control to have higher Tropical Fruit intensity, Fruit Intensity, and Body.

For the March 14 tasting, there was a preference for the control wine. There was no significant difference between wines. There was a slight tendency for the heat treatment to lower Fruit Intensity and Acidity. However, due to the small number of judges at this tasting, these results are very weak.

Overall, these wines were not found to be significantly different. There was a very slight tendency for the Control to have higher Tropical Fruit intensity, Fruit Intensity, and Body. No major preference trends could be seen between wines. In the future, more studies should be performed with Agrothermal heat treatment and its impacts on fruit chemistry. These studies should look into multiple grape varieties, as well as closely monitor disease progression. The use of Agrothermal heat treatment in conjunction with different vineyard spray regimes should be investigated as well. Although more studies are needed to confirm this, these preliminary results suggest that heat treatment may be a beneficial tool for East Coast viticulture.

Methods

A Petit Manseng block, VSP trellising (49 inches canopy height, 20-inch canopy thickness, 9x6ft spacing), was divided into separate sections, one section being a control and the other section being a treatment. The sections all represent relative similar geology, soil types, drainage, and elevation. They are also relatively close to each other within the block. The control section was not treated with the Agrothermal Systems device, whereas the treatment section was treated. Both blocks were hedged three times during growing season, leaf pulled three times, had sucker removal, foliar nutrient additions after bloom, cluster exposure after veraison, and haybail bird netting after veraison.

The experimental lot was treated with heat blast (HB) delivery to the canopy and fruiting zones using a proprietary protocol set forth by the manufacturer. Treatments varied in frequency due to (but not limited to), various stages of bloom, veraison, ripening, and weather events.

All treated blocks were farmed using a Kubota L5740 tractor utilizing PTO attachment with the Agrothermal Systems XT technology pulled behind the Kubota. All control blocks were farmed using a Kubota L5740 tractor utilizing PTO attachment and a Jacto Arbus 1000 sprayer. Both control and treatment had identical chemical spray regimes. Depending on stage of growth, the treatment block was sprayed with the AgroThermal Heat Systems spray from 1 to 4 times per month, beginning in veraison (May). The majority of sprays were performed starting around veraison. About 15 total sprays of the heat treatment were performed. There is no REI, and it is not dangerous for vineyard workers to work around the Agrothermal Sprayer while in use. The spray takes around 5-10 minutes to attach the unit, 10 minutes to set up the control box, 20-45 minutes to fine tune the amount of heat coming out of the unit (due to safety features being in place which were unnecessary), and 20-45 minutes to spray per acre. It can be used for frost protection by continuously spraying all night and morning. The equipment retails for $50,000 not including shipping (as of 2017). The equipment used a 100 gallon propane tank which effectively covered the entire 28 acre property without refilling.

Petit Manseng from both lots were harvested on October 10, 2017, with a yield of 3.67 and 3.37 tons per acre for the control and treatment, respectively. This resulted in an ESCV/CS of 1.3 and 1.4. There was some light rainfall just prior to harvest. Harvested grapes were refrigerated for 24 hours with 3 hours of ozone gas added on October 10, and 2.5 hours of ozone added on October 11. Both lots were destemmed on October 12 and then each lot received 5g innodose sprinkled on top of the grapes to mitigate skin oxidation. Each destemmed bin received 15 minutes of ozone before covered with lids. Destemmed grapes were then cold soaked for 24 hours, with ozone added to the refrigeration unit for 2.5 hours. Each lot was pressed separately on October 13, with Cinnfree at 25mL/bin. Juice received 30ppm sulfur dioxide, 10g/hL Bentonite, and 800g Lysozyme. The juice was racked off lees on 10/15 into separate tanks, set to 60°F, and inoculated with R4600 yeast at the same rate (approximately 16 ounces), with GoFerm (approximately 20 ounces) and Booster Blanc (approximately 23 ounces). On November 17 Lysozyme was added to the wine, and on November 29 the wine was racked to identical neutral French oak barrels with 44ppm sulfur dioxide added. Barrels were topped on December 29. 22ppm sulfur dioxide was added on January 4, and wine was bottled on January 9 for Research Exchange.

These wines were tasted on February 7 and March 14. For the triangle test, descriptive analysis, and preference analysis for the February 7 tasting, anybody who did not answer the form were removed from consideration for both triangle, degree of difference, and preference. Additionally, anybody who answered the triangle test incorrectly were removed from consideration for degree of difference and preference. Additionally, any data points for preference which did not make sense (such as a person ranking a wine and its replicate at most and least preferred, when they correctly guessed the odd wine) were removed.

In order to balance the data set to perform statistical analysis for descriptive analysis on the February 7 tasting, any judge who had not fully completed the descriptive analysis ratings were removed. In order to then make the number of judges between groups equivalent, one judge from group 1 was transferred to group 3, and another judge from group 2 was eliminated. This resulted in a final data set of 3 groups, each with 7 judges (considered as replications within groups, and groups were considered as assessors). Data was analyzed using Panel Check V1.4.2. Because this is not a truly statistical set-up, any results which are found to be statistically significant (p<0.05) will be denoted as a “strong trend” or a “strong tendency,” as opposed to general trends or tendencies. The statistical significance here will ignore any other significant effects or interactions which may confound the results (such as a statistically significant interaction of Judge x Wine confounding a significant result from Wine alone). The descriptors used in this study were Fruit Intensity, Tropcial Fruit, Minerality, Overall Aromatic Intensity, Acidity, and Body.

Due to the very small number of judges (3) at the March 14 tasting, only slight trends will be discussed for the sensory information.

References

Agrothermal Systems. “Thermaculture for vineyards and wine quality.” Accessed May 14, 2018. https://agrothermalsystems.com/thermaculture/wine-grapes/