The Impact of repeated years of Agrothermal Systems Heat Blast Treatments on Grape Ripening, Wine Chemistry, and Wine Quality in Petit Manseng (2018)

Shai Van Gelder

Barrel Oak Winery

Summary

Humidity and occasional rain during grape growing season is a challenge in Virginia viticulture. Agrothermal Systems has begun to market a tractor-pulled machine that generates and blows heat onto grape clusters with the claim this treatment increases yields and improves wine quality by increasing phenols and antioxidants1. However, few studies have been done and none have been done on East Coast fruit. In this study, a single replicated block of Petit Manseng was treated with heat blast according to a propriety schedule. Grape and wine chemistry were measured and wines were analysed for sensory characteristics. The portion of the vineyard treated with heat blast treatment resulted in higher yield (6.01 lbs/vine compared to 5.03 lbs/vine). Grapes receiving heat blast had lower malic acid levels and higher tannin content. Resulting wine also had lower malic acid. Wines produced from grapes receiving heat blast were distinguishable from control in a triangle test, with higher bitterness in the treated wine.

Introduction

In its promotional material, Agrothermal Systems claims its heat blast treatment reduces the need for fungicide, controls pests, increases yields and improves wine quality by increasing phenols and antioxidants1. If true, this intervention could be a valuable tool in Virginia’s humid climate. However, Dr. Tony Wolf, Professor of Viticulture and Director of the Virginia Tech Agriculture and Research Center, cautions that though “there is some physiologic precedent for the ‘heat-shock’ treatment” including expression of systemic acquired resistance (SAR) genes and related metabolites” the question remains if the detection of metabolites in grapes in lab studies translates to a treatment that alters fruit quality and wine quality within reasonable economic parameters (personal communication).

Heat blast treatment uses “a gas-operated, hydraulic fan heater system that generates a 300 °F hot air stream through the plant.”1 The heater is pulled behind a tractor at 3-4 mph and aims the hot air stream at the fruit zone. A video of the machine in action is posted on the website of the manufacturer1. In practice, heat is applied 10-12 times between bloom and harvest according to a proprietary schedule. When asked, two Virginia winemakers, Shai Van Gelder (Barrel Oak Winery) and Preston Thomas (Stone Tower Winery) estimated that, at a speed of 3-5 mph, treatment time ranges from 1-2.5 hours per acre depending on row spacing and length (personal communication).

The company website for Agrothermal Systems1 claims benefits of the treatments that include a 50% or more decrease in fungicides, an average 20% increase in harvest yields due to a 24% increase in fruit set, improved profits and enhanced quality. One internally generated study reports reduction in the incidence of powdery mildew in a Chardonnay vineyard in California. This study included replicate rows and showed a statistically significant decrease in disease incidence compared to RNA Fruit Wash with treatments every 2-3 days for two weeks2. Other internal work promotes alternating conventional pest control and heat blast. The rationale given is that heat will kill the fungal mycelium and soft bodied insects, diminishing disease pressure1.

In a study of heat blast usage in a Pinot Noir vineyard in Oregon, small increases in phenolics were found, but vintage differences were larger than treatment differences1. They also found small but statistically significant increases in antioxidant activity in laboratory testing with heat blast treatment. They explain these differences as the result of cellular responses to “instantaneous heat shock”, which are thought to “activate the plant self-defense system and increase its production of phenol and antioxidants – the main flavonoids in wine. The resulting wine exhibits enhanced flavor profiles, increased aromatic definition, and smoother texture.”1

Each of the above studies were reported by Agrothermal Systems. In an external study of the heat exposure, grape heating, and grape metrics at harvest after heat blast treatment in Merlot and Syrah were studied in a vineyard in Eastern Washington State3. They found that at a tractor speed of 4 mph, vines are exposed to hot air for 1.5 to 2 sec each, resulting in increases in grape temperature of 10-20 °F for 10-20 seconds. Grapes returned to initial temperature within 60 seconds. As heat from the vents diffuses exponentially in proportion to the distance, the heat blast exposure was an average of 149 °F in fruit zone, with large variation in cluster temperatures due to location on the vine. Heat also hit the upper portion of the trunk of the vine and the lower portion of the canopy at measurable levels. This study found no significant differences in fruit set, timing of veraison, pH, TA, or Brix in either Merlot or Syrah.

Though none of these studies explores a mechanism for action, other research has investigated the cellular response to high heat in Vitis vinifera grapes. Reinth et al (2014)4 examined the effect of 2 hours of exposure to 37 °C both during the day and at night. They documented physiological responses such as decreased berry weight, decreased sugar accumulation, delayed ripening and higher heterogeneity among berries. By examining RNA expressed during and following heat exposure, they found an increase in expression of heat shock proteins along with decreases in the expression of genes related to stilbene (resveratrol) metabolism, synthesis of phenolics (such as condensed tannins and anthocyanins), terpenes and carotenoids (these lead to norisoprenoids such as B damescone and B ionone, important flavor molecules). Abscissic acid, an important molecule in ripening and sugar accumulation, was also inhibited. Two hours of heat also led to an increase in the cellular pathway that consumes malic acid. Carbonnel-Bejerano et al (2013)5 tracked changes in gene expression with 2 days of heat exposure and found similar results. They specifically mention that heat exposure in leaves led to upregulation of antioxidant production, but grape exposure did not. They also found decreases in many membrane transport proteins and the enzyme needed to transform sugar in the grape, which leads to lower sugar accumulation. These studies would suggest the opposite effects on phenolics and flavor as those found in Oregon Pinot Noir.

Heat Blast is usually applied in the morning when ambient temperatures are cooler, presumably to induce the maximum change in temperature with treatment. However, the additional heat measured in the grapes by Gohil and Moyer (2014)3 was less than the natural heating the grapes would experience in the afternoon, leading one to question if the treatment is necessary. However, Reinth et al (2014)4 found that the grape response to heat stress when applied at night was somewhat different than the response when heat was applied during the day, presumably due to differences in overall metabolism during those times.

All previously reported field work has been done in dry climate areas (California and Eastern Washington). The following study aims to measure the effects of heat blast treatment in Virginia, where the summers are hot and humid. In this study, pest incidence was not quantified. Fruit quality was measured in terms of yield and chemistry.

A pilot study on a single block of Petit Manseng at Barrel Oak Winery in 2017 showed slight differences in fruit and wine chemistry such as slightly lower malic acid, slightly higher tannin and astilbin, and lower grape reactive factor. Lower mite pressure was observed but not measured. However, those data were not from replicated blocks in the vineyard. The purpose of this study was to determine the effect of a second year of heat treatment on Petit Manseng with the introduction of replication for vineyard parameters.

Methods

A single block of Petit Manseng in VSP trellising was divided into duplicate control (non-treated) and heat blast (treatment) sections. Rows run N/S with numbering beginning from the east. Rows 4-6 and 20-22 were designated as control rows. Rows 9-17 were designated as treatment sections.

The control section was not treated with the Agrothermal Systems device, whereas the treatment section received heat blast. All sections were farmed identically with regard to hedging, leaf pulling, sucker removal, foliar nutrient additions after bloom, cluster exposure after veraison, and haybail bird netting after veraison.

All treated blocks were treated using a Kubota L5740 tractor utilizing PTO attachment with the Agrothermal Systems XT device pulled behind the Kubota. This delivered a short burst of heat (150°F for 1-2 seconds) to the canopy and fruiting zones. Treatments were applied during bloom, veraison, and ripening, and varied in frequency depending on vine physiology and weather events. The treatment block received heat blast a total of 8 time between bloom and veraison. Both blocks were sprayed identically for pests according to the winery’s spray.

Replicate fruit samples were taken September 21 from the middle of the three rows designated for each treatment (row 5 and 21 for control blocks and rows 9 and 17 for treatment blocks). Both sections were harvested on October 11 and treated identically in the cellar according to the normal protocol of the winery. Though two replicates of each treatment (HB, no HB) were planned, low crop levels resulted in a single fermentation per treatment block.

Grapes were destemmed into 1 ton macrobins with alternating applications of 30ppm SO2 and 25 ml/bin Cinn Free at the destemmer and 2x5 gram packets of Inodose effervescent SO2 tablets sprinkled on the top to protect grapes from oxidation. Sealed bins were treated with ozone for 10 minutes and placed in the cold room overnight, then pressed the following day. Pressed juice was cold settled then racked to tank for fermentation at 60 °F. Juice was chaptalized to a target of 22.5 Brix (an addition of 2 Brix) and acid was adjusted to a target of pH = 3.2 (lowering treatment by 0.17 pH units and control by 0.22 pH units. Juice was inoculated with 2 lbs/1000 gallons Vin 31 yeast rehydrated in 2.5 lbs/1000 gallons GoFerm and an addition of 2.5 lbs/1000 gallons Booster Blanc. Fermentations were monitored for chemistry (Brix and temperature) once per day and sensory twice per day. After completion of fermentation, wine was racked off lees, treated with lysozyme and 30-40 ppm SO2. Wine was stored in hybrid stainless steel barrels with new oak staves and acacia heads.

Sensory analysis was completed by a panel of 27 wine producers. Wines were presented blind in randomly numbered glasses. Tasters were presented with three wines, two of one type and one of another, and asked to identify which wine was different (a triangle test). There were three tasting groups with the unique wine in the triangle test balanced between groups. Tasters were then asked to score each wine on a scale of 0 to 10 for fruit intensity, body and bitterness. They were also given open ended questions to describe the wines. Results for the triangle test were analyzed using a one-tailed Z test. Descriptive scores were analyzed using repeated measures ANOVA.

Results

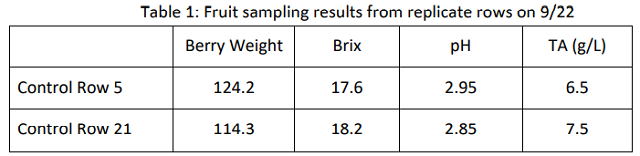

There were no notable differences in fruit chemistry or berry weight between treatments (Table 1). Field notes taken by Dr. Wolf from August 22 indicate fruit and canopy were in generally good condition and do not indicate large differences in disease, fruit development, or canopy condition. A 100 berry sample from replicate rows was taken on September 22 (Table 1). Dr. Wolf’s field notes once again indicate no obvious differences in the condition of the canopy or fruit on this day.

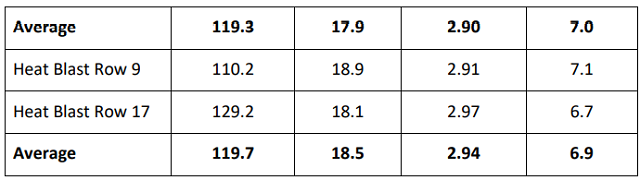

Due to low yields, fruit from replicate plots were combined into one press load per treatment. Yield at harvest was estimated to be 5.03 lbs/vine in the control plots and 6.01 lbs/vine in the heat blast treatment plots. Juice chemistry is shown in Table 2. The juice that did not receive heat blast had a higher sugar level, higher pH and higher YAN. Total acidity was similar for both treatments, however the heat blast treatment had less malic acid and more tartaric acid. There was little difference in grape phenolic measures (Table 3). Heat blast treatment has slightly higher tannin, however it is unlikely this translated to the wine since this is a whole cluster pressed white wine.

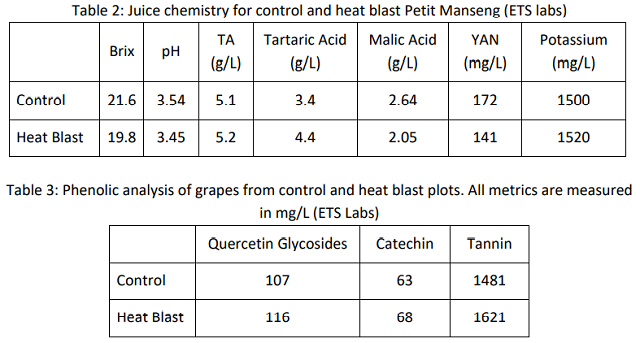

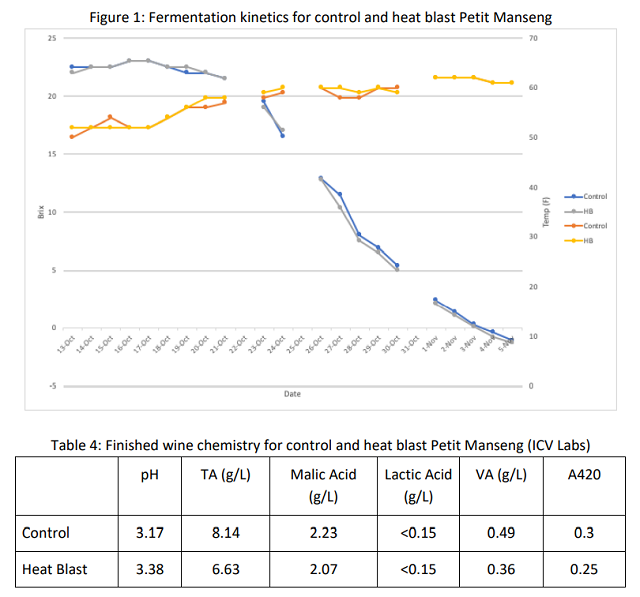

Fermentation progressed in a similar way for both treatments (Figure 1), with fermentations reaching a residual sugar <1.0 g/L at the same time. Finished wine chemistry was also similar with the exception of acidity (Table 4). Both juice and wine indicate a lower amount of malic acid in the heat blast treatment. This difference was not due to malolactic conversion, as both wines had no detectable lactic acid (Table 4). Loss of acidity maybe desirable with Petit Manseng but not with other white wine varieties.

In a triangle test of control vs. heat blast wines, 16 out of 27 respondents were able to distinguish the two wines, indicating the wines were significantly different (Z=2.65, p= 0.004). There were no significant differences in scores for fruit intensity (F=1.88, p=0.18) or body (F=1.8, p=0.20). However, the heat blast wine had a significantly higher score for bitterness (F=5.39, p=0.03) with the mean for the control wine equal to 3.19 (SD = 2.24) and the mean for the heat blast wine equal to 4.19 (SD=2.66). When asked what distinguished the wines in the triangle test, several respondents mentioned aromatic intensity, pineapple aromatics and bitterness.

Conclusions

- The heat blast treated portion of the vineyard had higher yield than the untreated portion of the vineyard, averaging 6.01 lbs/vine compared to 5.03 lbs/vine.

- Grapes from heat blast treated vines had lower malic acid and higher tannin than untreated vines.

- Wines from heat blast treated vines had lower malic acid and higher perception of bitterness than untreated vines.

References

(1) Agrothermal Systems Case Studies. https://agrothermalsystems.com/case-studies/. Accessed Jan 2018.

(2) Manduri, A.; Sarkar, D.; Fischer, M.; Vargas, C.; Shetty, K. Instantaneous Heat Shock Treatment in Grape During Pre-Harvest Stages Enhances Phenolic-Linked Medicinal Properties in Red Wine. Journal of Medicinally Active Plants 2017, 2 (5), 36–46.

(3) Gohil, H.; Moyer, M. Evaluation of Transient, in-Season Applied Heat to “Merlot” and “Syrah” Wine Grapes in Eastern Washington. HortTechnology 2014, 24 (6), 736 – 742.

(4) Reinth, M.; Torregrossa, L.; Luchaire, N.; Chatbanyong, R.; Lecourieux, D.; Kelly, M.; Romieu, C. Day and Night Heat Stress Trigger Different Trascriptomic Responses in Green and Ripening Grapevine (Vitis Vinifera) Fruit. BMC Plant Biology 2014, 14.

(5) Carbonnel-Bejerano, P.; Santa Maria, E.; Torres-Perez, R.; Royo, C.; Lijavetzky, D.; Bravo, G.; Aguirreolea, J.; Sanchez-Diaz, M.; Antolin, M. C.; Martinez-Zaptar, J. M. Thermotolerance Responses in Ripening Berries of Vitis Vinifera L. Cv. Muscat Hamburg. Plant and Cell Physiology 2013, 54 (7), 1200–1216.