Does addition of Rapidase Proteostab improve protein stability in unstable aromatic white wines? (2021)

Emily Pelton

Veritas Vineyard and Winery

Summary

Due to high levels of fungal pressure in the vineyard and pressure to pick before optimum maturity, Virginia white and Rosé wines often suffer from high levels of protein instability. However, large bentonite additions needed to achieve protein stability are also thought to affect the delicate aromatics of this wine and likely lead to relatively large volume losses. One approach to reducing protein instability in wine is the use of a targeted enzymes to break unstable proteins into smaller pieces that do not result in haze. Rapidase Proteostab is a liquid enzyme formulation produced from Aspergillus niger to reduce unstable protein concentration. In its intended use, juice is heated prior to treatment, however package instructions indicate there may be some efficacy even without heating. In this experiment, two stainless steel barrels of Sauvignon Blanc were fermented with the addition of Rapidase while two others were not. Fermentation with Rapidase caused no difference in the amount of bentonite that needed to be added to achieve protein stability in the finished wine.

Introduction

Due to high levels of fungal pressure in the vineyard and pressure to pick before optimum maturity, Virginia white and Rosé wines often suffer from high levels of protein instability. Sauvignon Blanc is a variety prone to high levels of protein instability even in vintages with relatively low fungal pressure. However, large bentonite additions needed to achieve protein stability are also thought to affect the delicate aromatics of this wine and likely lead to relatively large volume losses.

One approach to reducing protein instability in wine is the use of a targeted enzymes to break unstable proteins into smaller pieces to either take them out of solution earlier or to make them less likely to form a web. However, several considerations make this more difficult. The pathogenesis-related proteins that are responsible for most protein instability in wine in are generally resistant to proteases, and, most protease enzymes don’t work well at wine pH and temperature1,2.

The Australian Wine Research Institute (AWRI) has reported work on the use of a targeted protease to treat protein instability in wine2. Treatment involved first heating juice to 70-75°C (158-167°F), then treating with proctase enzyme, which is still active at juice pH. Juice heating causes proteins to unfold so that they are more susceptible to protease attack, and heating the juice also increases enzyme activity. When tested at both the laboratory and production scale, treatment with proctase showed efficacy comparable to bentonite in removing chitinase proteins. In a triangle test, a sensory panel was not able to distinguish wines fined to stability with bentonite from those treated with heat and proctase. It is difficult to assess if this treatment achieves protein stability, since the most commonly used test is really a measure of overall protein content. By its nature, proctase is not removing all proteins, only the unstable ones. AWRI is working on developing a test that is better suited to assess true protein stability in the winery2.

In 2020, Darren Michaels from Scottlabs mentioned in a webinar that Scottlabs had released an enzyme for degradation of unstable proteins. Rapidase Proteostab is a liquid enzyme formulation produced from Aspergillus niger to reduce unstable protein concentration. The product information includes instructions to heat the must by flash pasturization at 75°C for 1-2 minutes, presumably to denature the target proteins. However, product information states that “use with no heat treatment in juice and wine may improve protein stability”, but requires longer contact time and a higher dose. The purpose of this experiment was to determine if treatment of Sauvignon Blanc juice with Rapidase Proteostab during fermentation resulted in lower levels of protein instability, and therefore lower required bentonite addition, in the finished wine.

Methods

Sauvignon Blanc grapes were harvested on 8/19/21, refrigerated overnight, then whole cluster pressed with the addition of Cinn-Free and SO2. After setting for one day, juice was racked to a clean tank, then racked again to two stainless steel barrels per treatment and chaptalized. Juice was inoculated with QA23 yeast (Scottlabs) rehydrated in FG- Fermoplus Energy Glu. The same day, 10 ml/hL Rapidase enzyme was added to treatment barrels only. Fermentation was monitored daily for density and temperature. At the completion of fermentation, barrels were topped and SO2 was added. Samples from each barrel were sent to ETS for protein stability analysis. All other cellar operations were identical among all four barrels.

Results

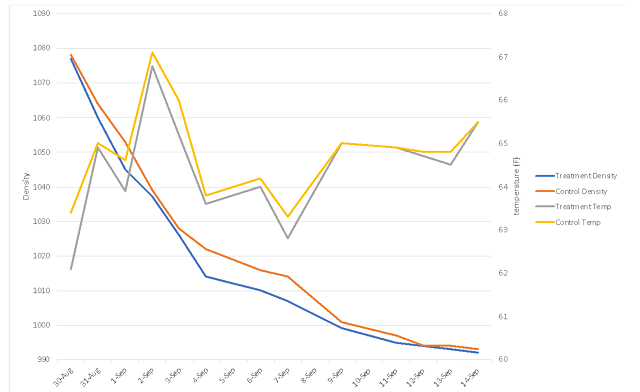

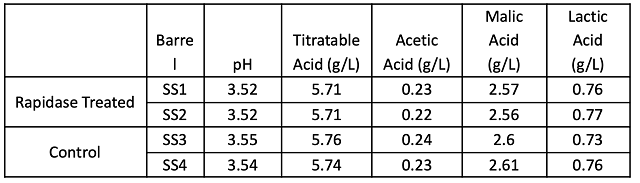

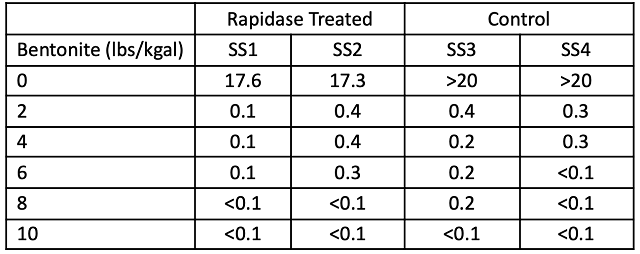

Addition of Rapidase Proteostab did not alter fermentation kinetics (Figure 1) or finished wine chemistry (Table 1). Enzyme treatment also did not alter the amount of bentonite needed to be added to achieve protein stability (Table 2). Due to the low level of needed addition, it is possible Rapidase may be useful in wines that require higher bentonite addition rates, or in wines with warmer fermentations.

Figure 1: Fermentation kinetics for Sauvignon Blanc with (treatment) and without (control) Rapidase addition

Table 1: Wine chemistry for four barrels of Sauvignon Blanc (ICV labs)

Table 2: Heat stability for four barrels of Sauvignon Blanc (ETS Labs)

References

(1) Waters, E. J.; Muhlack, R. A.; Pocock, K. F.; Colby, C.; O’Neill, B. K.; Jones, P. Preventing Protein Haze in Bottled White Wine. Australian Journal of Grape and Wine Research 2005, No. 11, 215–225.

(2) Robinson, E.; Scrimgeour, N.; Marangoni, M.; Muhlack, R.; Smith, P.; Godden, P.; Johnson, D. Beyond Bentonite. Wine and Viticulture Journal 2012, No. November/December, 24–30.