Comparing three bentonite products for efficacy, packing, and color stability (2018)

Scott Dwyer and Students

Chemeketa Community College

Summary

Under the direction of Scott Dwyer, students at Chemeketa Community College undertook a series of experiments exploring the properties of different bentonite products. Testing showed that the rates of bentonite predicted to achieve protein stability differed depending on which bench test was used (Bentotest vs. fast heat test) and which bentonite was used. Lees compaction of bentonite was both bentonite-dependent and wine-dependent. Bentonite fining of Rosé wine led to decrease in color intensity and increased hue. This effect was more pronounced in a Rosé with higher initial color intensity.

Introduction

There are many different bentonite products available on the US market with differences in origin, chemistry, and processing that lead to differences in performance. Under the direction of Scott Dwyer, students at Chemeketa Community College in Salem, Oregon undertook a series of experiments to explore several bentonite products for efficacy and efficiency in a lab setting. Three bentonite products were chosen for study:

Microcol Alpha (Laffort) (MA) is a sodium bentonite with moderate compaction. Product information claims “aromatic preservation” and “color preservation”. MA is rehydrated in 10 times its weight in hot water for 12-24 hours.

Vitaben (Gusmer) (VB) claims to produce reduced lees, have higher activity, and easier handling than other bentonites. Product information does not specify if it is sodium or calcium based. It is rehydrated in cold water. Rehydration time is not listed.

KWK Kwik (KWK) is a sodium bentonite. Product information claims it removes proteins but not tannins. This product requires rehydration in hot water. Rehydration time is not specified in product information; 12 hours is generally recommended.

Several questions were explored:

- Comparison of Protein Stability Test Predictions and Bentonite Product Efficacy

- Comparison of compaction rate of three bentonites in six wines

- Change in Rose color with fining

Comparison of Protein Stability Test Predictions and Bentonite Product Efficacy

Introduction

Several tests can be utilized for protein stability. These tests differ by the basis of protein precipitation, usually relying on either heat or acid to hasten instability. In this study, two testing methods were used to predict the rate of bentonite needed for stability: the Bentotest (an acid-based test) and the fast heat test.

The Bentotest is a commercially available preparation of phosphomolybdic acid. The test is performed by adding 1 part reagent to 10 parts wine at room temperature, creating a very low pH environment. The solution is then allowed to incubate a short time (3-5 minutes). This rapid test is a measure of protein precipitation under acidic conditions and requires no heating.

The fast heat test subjects the wine to high heat (80°C) for a short time (30 minutes to 6 hours) to denature proteins. Turbidity is measured before heating and after wine is allowed to cool as an indication of unstable proteins. This technique requires more time, but has been shown to produce precipitates closer to the type formed during wine aging than other tests1.

Methods

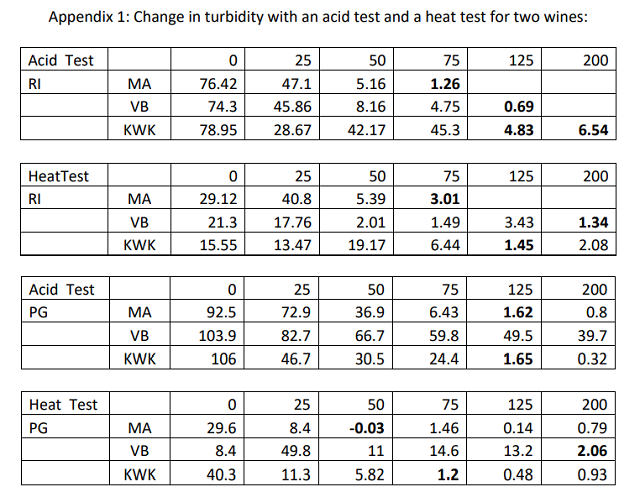

Prior to heat or acid tests, wines were treated with stock solutions of bentonite to a final concentration of 0, 25, 50, 75, 125, and 200 g/hL. Bentonite was allowed to settle then wine was decanted off bentonite but not filtered. Each wine/bentonite pair was treated with each concentration of bentonite.

For the acid test, 1 mL of Bentocheck reagent was added to 10 mL of bentonite-fined wine. Tubes were mixed by inversion and incubated 1 minute prior to checking turbidity. For the heat test, wine was heated for 6 hours at 80°C and allowed to cool before measuring final NTU. Turbidity measurements before and after treatment with acid (Bentotest) or heat were recorded. A change in turbidity <2.0 NTU was considered stable. In this trial, wines were not filtered prior to heating or treatment with Bentotest reagent.

Results

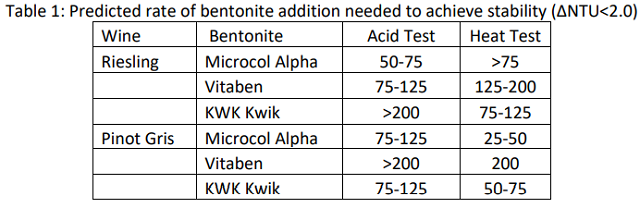

Two wines, a Riesling and a Pinot Gris, were fined with six doses of bentonite and tested for protein stability using a Bentotest and a fast heat test (Table 1, Appendix A). Each wine was tested with three different bentonite products. The acid test predicted a higher rate of bentonite addition in four of the six tests while the heat test predicted a higher rate in two of six tests. There was not agreement between tests for any of the six wine/bentonite pairs. At times these differences differed in predicting stability within 25 g/hL of bentonite, but differences as large as 100 g/hL were seen.

When comparing efficacy of bentonite products, Microcol Alpha achieved stability at the lowest rate in both wines while Vitabin required the highest rate for both wines.

Comparison of compaction rate of three bentonites in six wines

Introduction

A major concern with bentonite is volume loss. Waters et al (2005) cites an estimate that the worldwide cost of bentonite fining of wine per year is on the order of $300-500 million2 while Robinson et al (2012) cites a figure of $1 billion3. These costs are largely due to wine lost during racking off bentonite lees. If 5-10% of the volume is lost at this step4, these costs add up quickly.

Methods

In this study, 6 wines were treated with five concentrations of three different bentonite stock solutions and allowed to settle. After settling, the height of the bentonite column in the container was measured.

Results

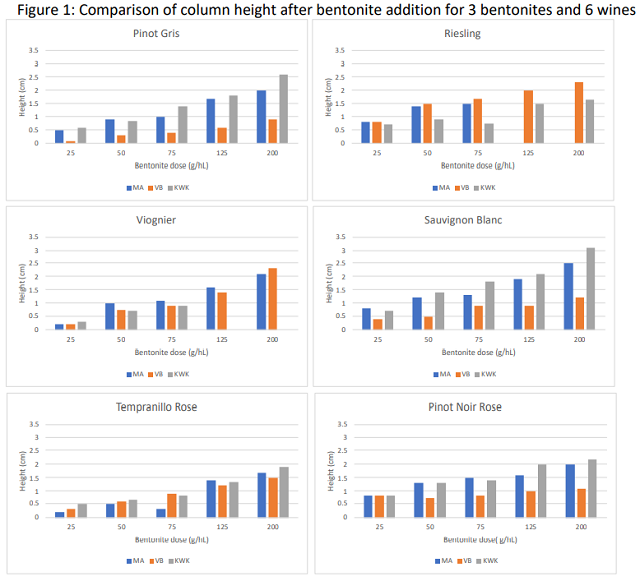

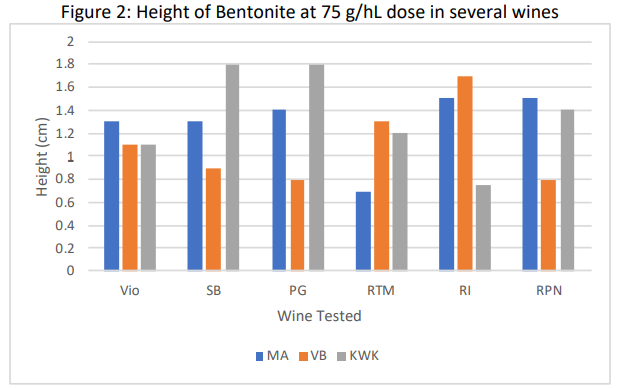

Relative compaction among bentonite products varied considerably depending on the wine (Figure 1, 2). For example, Vitaben showed very good compaction in Pinot Gris, with the shortest column at all doses, but much less compaction in Riesling), with the highest column of the products tested.

Also, the height of the column at a given rate differed by wine for each product. For example, at 75 g/hL each bentonite product had very different column height depending on the wine (Figure 2). Though bentonite settling is affected by the properties of the bentonite itself (sodium vs. calcium), it is also affected by the wine matrix. There is differential packing of bentonite sheets in different chemical matrices of wine5.

Comparing bentonite products for color stripping in Rosé

Introduction

Bentonite fining for protein stability is based on charge. Bentonite is negatively charged when hydrated. Proteins are mostly positively charged at wine pH. In its simplest form, bentonite fining is the attraction of positively charged proteins to negatively charged bentonite, that then settles out of the wine.

Unfortunately, there are other components of wine that are also positively charged, including anthocyanins. Red wines are rarely treated with bentonite because the tannins in the wine have already bound most of the protein. Also, red wines are generally opaque so protein precipitate will not be as noticeable. However, this is not the case with Rosé. Rosé has many fewer tannins and is often presented in clear bottles to showcase the color. Therefore, color stripping during bentonite fining is a concern in Rosé wine.

Methods

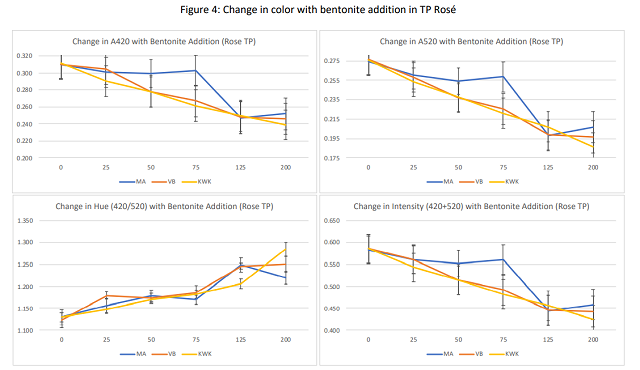

In this study, three bentonite products were used to fine two Rosé wines at five different rates. Absorbance at 420 nm and 520 nm was read for each wine after fining. Absorbance at 420 nm is a measure of the amount of yellow and brown color in wine while 520 nm measures the amount of red color (a proxy for anthocyanins) in the wine. The hue is calculated as the ratio of absorbance at 420/520. A higher number indicates a more yellowish color while a lower number indicates a shift to the red part of the spectrum. Color intensity is simply the sum of A420 + A520.

Each test was done in triplicate. Values reported are the average of three tests. Error bars represent the standard deviation from the mean.

Results

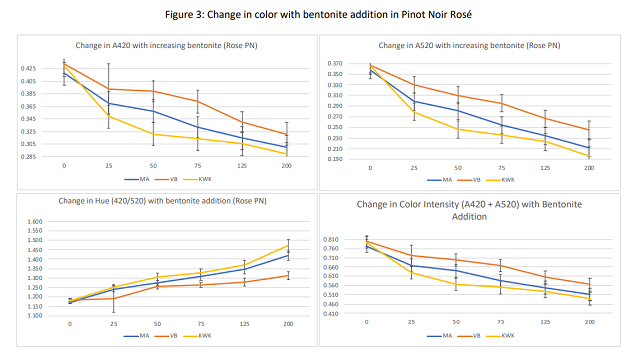

In the Pinot Noir Rosé, all three bentonite products showed a decrease in A420, A520, and color intensity, as well as an increase in hue (Figure 3). These trends are consistent with stripping of anthocyanins. When comparing products in all measures of color loss, the same trend appears in each case: KWK>MA>VB. This trend was also seen in the opposite direction with the shift in hue from red to yellow.

However, this same trend was not seen in TP Rosé (Figure 4). There was less separation among products overall, and in general, KWK and Vitaben appeared to strip more color than MA. TP Rosé began with less color overall, so it is possible that at lower pigment levels, color stripping is less prevalent.

Conclusions

- Heat test and acid tests produced different predictions for the amount of bentonite needed to achieve stability for all bentonites in the two wines tests. Neither test was consistently more stringent than the other, and tests sometimes differed by large amounts (up to 100 g/hL of bentonite).

- In the two wines tested, Microcol Alpha appeared to have the best binding efficiency, with the lowest predicted rate of addition needed to achieve stability.

- Bentonite compaction rate varied considerably by wine. No single bentonite product showed consistently better packing at the same rate in each of the six wines tested.

- Bentonite addition led to color stripping in Rosé. KWK and Microcol alpha stripped more color in one of the two wines tested. There was not as clear of a difference in the second wine tested.

References

(1) Esteruelas, M.; Poinsaut, P.; Sieczkowski, N.; Manteau, S.; Fort, M. F.; Canals, J. M.; Zamora, F. Comparison of Methods for Estimating Protein Stability in White Wines. American Journal of Enology and Viticulture 2009, 60 (3), 302–311.

(2) Waters, E. J.; Muhlack, R. A.; Pocock, K. F.; Colby, C.; O’Neill, B. K.; Jones, P. Preventing Protein Haze in Bottled White Wine. Australian Journal of Grape and Wine Research 2005, No. 11, 215–225.

(3) Robinson, E.; Scrimgeour, N.; Marangon, M.; Muhlack, R.; Smith, P.; Godden, P.; Johnson, D. Beyond Bentonite. Wine and Viticulture Journal 2012, No. November/December, 24–30.

(4) Blateyron, L.; Meistermann, E.; Trottier, C. Stabilisation Proteique Des Vins Blancs et Rose: Etude Comparative Des Bentonites et Rechaerche d’une Approche Raisonnee Des Traitements. Congres OIV 2007.

(5) Dordoni, R.; Colangelo, D.; Giribaldi, M.; Giuffrida, M. G.; De Faveri, D. M.; Lambri, M. Effect of Bentonite Characteristics on Wine Proteins, Polyphenols, and Metals under Conditions of Different PH. American Journal of Enology and Viticulture 2015, 66 (4), 518–530. https://doi.org/10.5344/ajev.2015.15009.

(6) Zoecklein, B. Bentonite Fining of Juice and Wine. Enology Notes Online Publications 1988.