Bentonite 101

Joy Ting

The most common approach to removing unstable protein from wine is the use of bentonite. Bentonite is a volcanic montmorillonite clay that, in the US, is mined in Wyoming. There are several different kinds of bentonite based on the geographic origin with sodium and calcium based bentonites the two main categories on the market. Specifics of bentonite type will be covered in a separate newsletter, including experiments for efficacy and a discussion of efficiency.

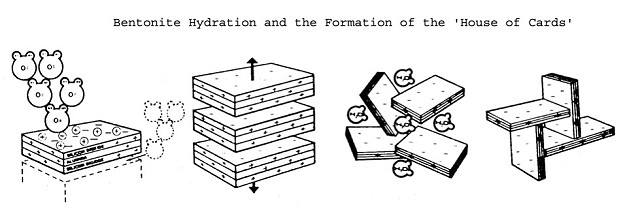

Bentonite has a physical structure that looks like many overlapping sheets (Figure 1). These sheets are made up of crystals of tetrahedral silica dioxide and octahedral aluminum hydroxide. When hydrated in water, the sheets take on negative charges which causes them to repel one another. This can be seen in the physical swelling that occurs when bentonite is added to water in the winery. Once fully hydrated, the sheets orient themselves to minimize contact with other sheets that have the same charge. The flat ends of the crystals are positivity charged, which cause the whole structure to look like a house of cards (1).

Figure 1: Bentonite hydration, from Zoecklein 1998

Once it is swelled, bentonite has a high density of negatively charged particles. When added to wine, positively charged proteins bind to these negatively charged sheets. Charge neutralization causes proteins to clump to one another, and to the bentonite sheets, to form precipitates that drop to the bottom of the tank. Different proteins have different amount of positive charge on their outer surface, so will interact with bentonite in stronger or weaker ways. Unfortunately the most unstable proteins are also closest to their isoelectric points, meaning they are close to having a net charge of zero. Therefore the most unstable proteins are the least likely to bind to bentonite.

Bentonite fining is based simply on charge, so anything that is positively charged will be bound. Potassium in wine is present in its positively charged form and may also bind to bentonite. This means that potassium is taking up binding sites on the bentonite, leading to higher rates needed to remove protein. If stability testing is done prior to cold stabilization, and fining is done after cold stabilization, the test may overestimate the amount of bentonite needed, as potassium is removed during cold stabilization.

Anthocyanins are also positively charged at wine pH, and may bind to bentonite, which will strip color from the wine. This is one reason bentonite is rarely used on red wines.

Despite the drawbacks, bentonite is still the most widely used fining agent for protein stabilization because it is thought to have little impact on sensory characteristics compared to other fining agents (2,3).

When, why and how bentonite is used

Bentonite can be used at several stages in the life of the wine including juice settling, fermentation and pre-bottling preparations. Pre-fermentation, the role of bentonite is mostly to settle juice lees. Jackson (2014) suggests adding bentonite after an initial settling period to help compact the lees. This is a useful approach for winemakers who wish not to use settling enzymes. Bentonite use on juice can also be used to remove laccase in Botrytis-affected fruit (2). Soluble protein content can increase by 50% during cold settling due to pulp exposure (3,4) and the use of bentonite to settle juice may limit the increase in protein extraction coming from must during long settling times (3).

In a study testing the effects of bentonite pre-fermentation and during fermentation, Weiss and Bisson (2002) found that, at higher rates (36 g/hL), juice fining slowed fermentation and increased the total fructose in the final wine in some, but not all, of the lots they tested. Juice fining had no effect on amino acid composition nor YAN, though it reduced total protein in some cases. Lagging fermentation was not revived with nutrients, so they hypothesize an essential element such as sterols, fatty acids or phospholipids may have been taken out. Despite changes in overall protein content, juice fining did not change protein stability of the final wine (5).

Bentonite can also be added during fermentation with the intention of taking proteins out of solution with less effect on the aromatics of the wine. The rationale here is that many aromatics are still bound to precursor molecules during fermentation, so they are less susceptible to fining. Juice pH is generally lower than wine pH, which presumably increases the adsorption rate of proteins to bentonite when compared with the finished wine. Protein-bentonite adsorption has been shown to occur quickly, within 30 seconds of contact (6), and continued exposure of proteins in juice to bentonite that is mixed by the activity of fermentation itself provides continual accessibility to bentonite binding sites. Common rates for bentonite at this stage range from 25-40 g/hL, and it is commonly reported that addition of bentonite during fermentation can reduce bentonite addition rates later (3). Use of much higher rates is common in cold climate growing regions such as Germany (Maggie McBride Haek, Scottlabs, personal communication). Scottlabs has recently added a bentonite product specifically marketed to fermentation (Fermobent) with suggested rates of 200-300 g/hL for juice with high protein content.

Unlike their findings with juice fining, Weiss and Bisson (2002) found an increase in fermentation rate when wine bentonite was present during fermentation, possibly due to CO2 degassing. They also found a notable reduction in overall protein, especially at rates of 36 and 60 g/hL. However, as mentioned before, there is poor correlation between overall protein content and protein stability. This study did not test resulting protein stability.

Bentonite use both before and during fermentation is not uncommon in Virginia. In a survey of Virginia winemakers with 35 responses, 25% responded that they use bentonite during juice settling, 20% use it during fermentation and 8% replied they use it during both settling and fermentation.

The most common use of bentonite, however, is after the completion of fermentation, usually in the pre-bottling stage. At this time, bentonite addition rate can be determined by lab testing for each individual wine to be bottled. As mentioned above, it is important this testing occur after all other cellar operations have been completed, as any change in the chemical environment of the wine due to blending, pH adjustments, cold stabilization, fining or filtration can alter the protein stability of the wine. It is also important to do the bench test with the same type and lot number of bentonite that will be used to treat the wine, as bentonite can differ significantly among brands and even production lots.

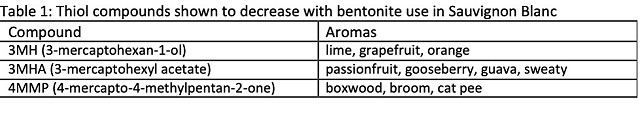

In a study testing the effect of fermentative vs. post-fermentative bentonite fining on aroma compounds in Sauvignon Blanc, Vela et al (2017) found that bentonite was more effective in removing proteins post-fermentation, meaning less bentonite was used overall. Despite high addition rates needed to achieve protein stability (100 g/hL), they found no significant differences in ethyl esters or acetates, and no impact on aroma in sensory analysis. There were differences, however, mainly in the thiol content. All three major thiol components known to characterize aromas of Sauvignon blanc (Table 1) were decreased with bentonite use, and the decrease was larger when bentonite was used during fermentation compared to its use on the finished wine. These results led the authors to hypothesize that bentonite interacts more strongly with thiol precursors than finished thiols (7).

Despite its widespread use, there is still much debate as to the best time to use bentonite and the potential impacts bentonite fining has one wine. Effects may be different for different wines. Therefore, each winemaker must decide for him or herself what is the best approach.

References

(1) Zoecklein, D. B. Wine Proteins and Protein Stability. Virginia Tech Enology Notes Winemaking Topics.

(2) Zoecklein, B.; Fugelsang, K. C.; Gump, B. H.; Nury, F. S. Wine Analysis and Production; Springer: New York, 1995.

(3) Jackson, R. S. Wine Science: Principles and Applications, 4 edition.; Academic Press: Amsterdam, 2014.

(4) Waters, E. J.; Muhlack, R. A.; Pocock, K. F.; Colby, C.; O’Neill, B. K.; Jones, P. Preventing Protein Haze in Bottled White Wine. Australian Journal of Grape and Wine Research 2005, No. 11, 215–225.

(5) Weiss, K. C.; Bisson, L. F. Effect of Bentonite Treatment of Grape Juice on Yeast Fermentation. American Journal of Enology and Viticulture 2002, 53 (1), 28–36.

(6) Blade, W.; Boulton, R. Adsorption of Protein by Bentonite in a Model Wine Solution. Am. J. Enol. Vitic 1988, 39.

(7) Vela, E.; Hernández-Orte, P.; Castro, E.; Ferreira, V.; Lopez, R. Effect of Bentonite Fining on Polyfunctional Mercaptans and Other Volatile Compounds in Sauvignon Blanc Wines. American Journal of Enology and Viticulture 2017, 68 (1), 30–38.