Sulfur Dioxide-Free Winemaking with Merlot (2015)

Matthieu Finot

King Family Vineyards

Summary

Identically harvested Merlot was stored overnight in cold room before being processed and divided into 2 identical lots. One lot was produced using a “traditional” protocol, the other using a sulfur free production protocol.

Traditional protocol:

- Grapes are being sorted, destemmed not crushed into tBin

- while filling the Tbin SO2 4.5g/hl

- Same day: Yeast FX10 12.5g/hl

- No cold soak

- At the end of maceration inoculation with bacteria Lactoenos 450 pre ac

- Press (blend free run and press wine)

- Clean racking after one day of settling in one new oak and one 3 year old barrels

- once MLF completed, SO2 15g/barrels

Sulfur Free Protocol:

- Grapes are being sorted, destemmed not crushed into tBin

- while filling the Tbin zymaflore alpha (TD) 30g/hl

- Same day: goferm 30g/hl and Yeast FX10 20g/hl

- No cold soak

- At the end of maceration inoculation with bacteria Lactoenos 450 pre ac

- Press (blend free run and press wine)

- Clean racking after one day of settling in one new oak and one 3 year old barrels (identical to lot 1)

- once MLF completed, micro stab (chitosan) 4g/hl

Sensory Results

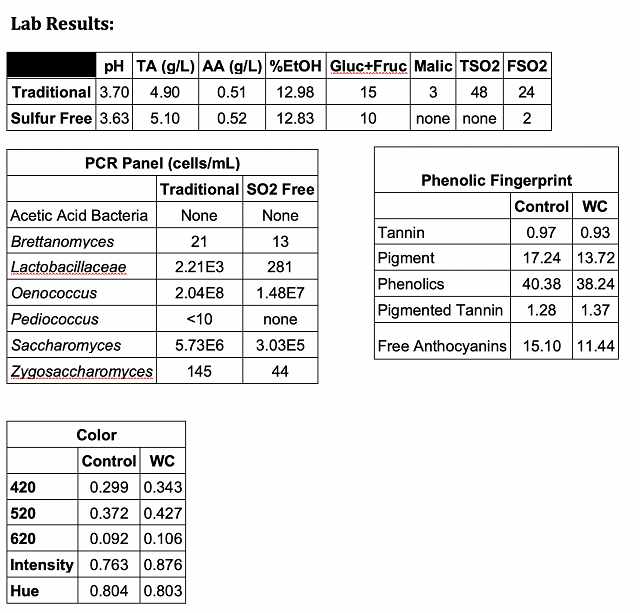

There were very little chemical differences between the control and low SO2 treatments. The traditional method seemed to have a higher microbial presence. The traditional method seemed to result in higher phenolic extraction (probably due to increased extraction from sulfur dioxide), but higher color intensity was found in the SO2-free wine. This is likely due to less monomeric anthocyanin bleaching.

There was no significant sensory difference (p<0.05) between the Control (traditional) and Trial (low sulfur protocol). However, of those that responded correctly (n=13) 69% preferred the control and 31% preferred the trial.