Reducing SO2 at crush with the non-Saccharomyces yeast BioNature (Lamothe Albeit) in Petit Verdot

Danielle Tessaro/Luca Paschina

Barboursville Vineyards

Summary

Many winemakers are looking for alternatives to the use of SO2 for microbial control. Several strains of non-Saccharomyces yeast are now commercially available for bioprotection as well as aroma/flavor enhancement. The purpose of this experiment was to compare the chemistry and microbiology of Petit Verdot after grapes were treated with either 25 ppm SO2 or 40 g/hL Bionature. There were no notable differences in wine chemistry, volatile acidity, or microbiology in the finished wines. The 2019 vintage was one with very little rainfall or disease pressure. Inoculation with Bionature controlled microbial growth as well as 25 mg/L SO2 addition at crush.

Introduction

Many winemakers are looking for alternatives to the use of SO2 for microbial control. Despite its prowess as an antioxidant and antimicrobial agent in wine, SO2 may have a negative effect on wine quality such as bleaching color, inactivating thiamine, and favoring production of H2S. Furthermore, it may have limited efficacy in musts with very high pH, such as Petit Verdot1. One alternative to the use of SO2 at crush is the use of selected strains of bioprotective non-Saccharomyces yeast.

Grapes enter the winery covered in microbes from the vineyard. To date, 52 different species of yeast from 22 different genera have been identified on grapes including Hanseniospora (AKA Klockera), Candida, Pichia, Hansenula, Metschnikowia, Sporoblomyses, Cryptococcus, Thodotorula, and Aurobasidium1. The cast of characters changes as grapes ripen, with the greatest abundance of microbes present in the last few weeks1. Healthy grapes are generally inhospitable environments for any microbe because they are covered in plates of wax that form a cuticle to hold in nutrition and repel water. Microbes cluster around the stomata or next to cracks in the cuticle where seepage from the openings provides both water and nutrients. The overall microbial load on grapes depends on environmental factors such as climate, altitude, variety, age of grapes, disease pressure and vineyard practices. Fog, rain, and fruit damage (like that seen in wet vintages like 2018) quickly transform the microbial desert of grape skins into an oasis. Cells that are present in small numbers quickly multiply when given the chance1. For example, Botrytis infection can increase the overall abundance of microbes by 1000x. Grapes with sour rot have significantly higher microbial diversity and abundance2. Insect pressure will also increase abundance due to increased vectoring from diverse environments3. The overall inoculant of non-Saccharomyces yeast and bacteria coming into the winery from the vineyard on the grapes is often larger than the inoculant of selected Saccharomyces yeast added at the beginning of fermentation1.

Non-Saccharomyces yeast have several impacts on the wine, both positive and negative. Klockera apiculata (aka Hanseniaspora uvarum) is a common member of the non-Saccharomyces yeast community found on grapes1,4. This yeast strain is easily identified under a microscope by its lemon shaped cells. It is tolerant to up to 100 mg/L SO2, can grow at low temperature (such as that found during cold soak), and can produce both acetic acid and ethyl acetate (which smells like nail polish remover) under aerobic conditions3. Other offenders in the non-Saccharomyces yeast community include Pichia guilliemondii, a film forming yeast prevalent in warm conditions when fermentation is delayed. This yeast can form spores that become resident in barrels and produce ethyl acetate and 4 ethyl phenol (which can smell like band-aid, wet dog, horse sweat)1–3.

Many spoilage bacteria also come into the winery on grapes. Sour rot and Botrytis increase the prevalence of Acetobacter, Gluconobacter and Gluconacetobacter, all of which produce acetic acid. Several Lactobacillus species (hilgardii, plantarum, casei) and Pediococcus (damnosus) are also residents of mature grapes. These can produce acetic acid, mousy flavor and biogenic amines (which have names like putrescine and cadaverine…). They may also produce polysaccharides that lead to ropy texture1,3,5.

In addition to outright spoilage, high levels of native flora may also cause nutrient depletion early in fermentations that limit nutrients available to Saccharomyces, potentially leading to stuck fermentations6,7. In a study of nutrient depletion by non-Saccharomyces yeast species, Medina et al (2012)6 found that Metchnikowia, a non-Saccharomyces yeast strain present in potentially high numbers on grapes8, consumed YAN quickly within the first few days of fermentation. Mimicking what may be occurring in fermentations with cold soaking or delayed inoculation, sequential inoculation with Metchnikowia followed by Saccharomyces led to stuck fermentations that could be resolved with nutrient addition. In the same study, Hanseniaspora, another prevalent member of the grape microbiota, did not show large YAN depletion (90% of the YAN remained 3 days after inoculation with this species), however it did deplete thiamine, an essential vitamin for Saccharomyces. Excessive use of SO2, as would occur in vintages with high microbial load, also leads to reduction in thiamine, further increasing the potential for stuck fermentations.

Despite the risks, there are also some benefits to having a rich microbial community early in fermentation. Several non-Saccharomyces yeast species have been shown to produce positive compounds that add complexity to wine aroma such as esters, higher alcohols, glycerol, succinic acid and thiols. Proteases produced by non-Saccharomyces yeast have been shown to break down cells and add nutrients, ultimately making a more protein stable wine. Some produce glycosidases that help unmask aromas compounds that are bound to sugar molecules. Others produce enzymes to break down polysaccharides that would otherwise inhibit clarification and filtration. Lachanacea thermotolerans has been shown to consume acetic acid, reducing volatile acidity1,8,9. It is likely these are some of the mechanisms that occasionally lead winemakers to employ ambient fermentations.

Many winemaking decisions affect the abundance and diversity of the microbial community present at the beginning of fermentation. Mechanical harvesting and long transport times, especially at warm temperatures, can lead to a high microbial load8,10. As soon as the grapes are crushed, nutrients are released to feed the organisms that are present. Klockera (Hanseniaspora) is often the most abundant species on the grapes , and remains prevalent until alcohol levels rise above 4-7% and oxygen is used up4,11. The low pH environment of the juice, rising alcohol, rising temperatures, and presence of phenolics tend to inhibit spoilage organisms in early fermentation. Harvesting wet grapes, prolonged cold soak, cool fermentation conditions, low inoculant of yeast, and lack of clarification (for white wines) can all lead to higher counts of yeast and bacteria in the fermentation4,12

In wet vintages such as 2018, the prevalence of damaged berries and wet grapes likely increased the inoculant of non-Saccharomyces microbes in fermentation and may have contributed to overall higher volatile acidity in wines that year. One approach to microbial management is to use higher than normal levels of SO2. Though SO2 has efficacy against some microbial spoilage, many of these microbes (such as Hanseniaspora) have high tolerance to it. Much of the SO2 added at crush is lost as it binds to grape solids that are prevalent in red wine fermentations, making it less effective. High SO2 additions can also bind thiamine and slow down or halt fermentation, and may even select for SO2 tolerant microbes that will cause spoilage during aging13,14. Still, fermentations that have some SO2 added at crush do tend to have faster onset of fermentation (leading to lower potential for spoilage) and steadier kinetics (Egli et al 1998).

Another addition to the toolkit for the prevention of microbial spoilage is to use a selected strain of bioprotective non-Saccharomyces yeast. Several strains of bioprotective yeast have been developed as commercially available products that inhibit the activity of spoilage organisms without depleting nutrients, undergoing fermentation, or inhibiting Saccharomyces. These strains are generally tolerant to SO2, so they can be used as an additional antimicrobial measure. Different strains use different mechanisms for bioprotection. One strain of Torulaspora delbrueckii has been shown to produce a killer toxin, TdKT, that uses ß-glycanase and chitinase activity to attack the cell walls of spoilage yeast15. Not all strains of T. delbrueckii tested had this activity, and if they did, it was not active against all of the soilage yeasts tested. Several strains of Metschnikowia pulcherrima have been shown to have broad and effective antimicrobial action against spoilage microbes. These employ pulcherriminic acid, which depletes iron from the surrounding medium to cause nutrient limitation. In addition, the presence of M. pulcherrima changed the gene expression of S. cerevisciae such that the fermentation yeast produced 40% less acetic acid and 12% more glycerol16.

Despite these promising results, it is important to keep in mind these bioprotectors cannot make up for poor cellar practices. James Osborne’s lab at Oregon State University conducted a series of experiments testing the ability of commercially available non-Saccharomyces yeast to reduce growth of Hanseniaspora uvarum and reduce the spoilage compounds made by this microbe (acetic acid and ethyl acetate). They used a model grape juice to grow mono-cultures and co-cultures of H. uvarum with several commercially available non-Saccharomyces yeast marketed as bioprotective (three Methchnikowia, three Lachanacea, and four Torulaspora). Each strain of bioprotective yeast decreased the level of acetic acid, and the number of H. uvarum cells present relative to mono-cultures of just H. uvarum. A single strain (M. fruticola) was further tested in Pinot noir must with and without cold soaking, at three levels of inoculation with H. uvarum. The number of H. uvarum cells decreased in cultures when H. uvarum was inoculated at low levels (1x103 cells/mL) but not high levels (1x106 cells/mL). At all levels, inoculation with M. fructicola decreased ethyl acetate and acetic acid levels relative to control, but high levels of H uvarum still led to high levels of ethyl acetate (20-30 mg/L) and acetic acid (175-200 mg/L) produced during cold soak. After fermentation was complete, there were no significant differences in ethyl acetate or acetic acid between “no cold soak” control and cold soaked wines treated with M. fructicola. The take-home message here seems to be that though non-Saccharomyces yeast can help, they cannot overcome high levels of H. uvarum inoculant caused by damaged grapes or long cold soaking17.

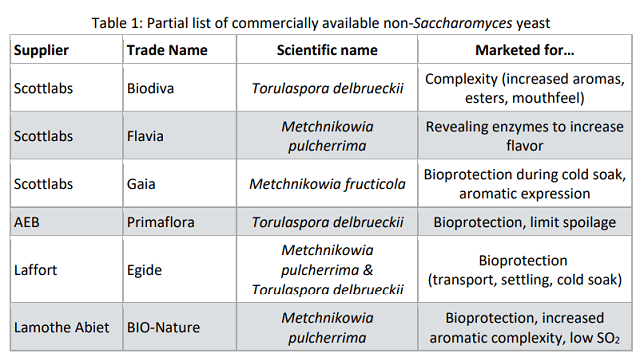

Several strains of non-Saccharomyces yeast are now commercially available for bioprotection as well as aroma/flavor enhancement (Table 1). BioNature from Lamothe-Abiet is a selected strain of Metchnikowia pulcherrima marketed for bioprotection as well as increased aromatic complexity. This strain was selected from 77 isolates for its low fermentation kinetics, low production of H2S, strong inhibition of Brettanomyces bruxellensis, Hanseniaspora uvarum, and Candida apicola. It can be used instead of or in conjunction with sulfur dioxide (It is resistant to up to 50 mg/L of SO2)1. The purpose of this experiment was to compare the chemistry and microbiology of Petit Verdot after grapes were treated with either 25 ppm SO2 or 40 g/hL Bionature.

Methods

Fruit was hand harvested from the same vineyard rows on Sept 13 and destemmed the same day. The BioNature treatment received 40 g/hL BioNature sprinkled onto the grapes at crush while the control received 25 pm SO2. Destemmed grapes were transferred to fermentation tanks by a must pump. Grapes were held in tank with CO2 gassing without pumping over for two days, then both tanks were inoculated with 25 g/hL FX-10 rehydrated in 25 g/hL GoFerm and 20 g Fermaid O. Fermentations received two pumpovers of 1.5 volumes of the tank per day for the duration of fermentation. Nutrients (20 g/hL Fermaid K and 20 g/hL DAP) were added at 1/3 Brix depletion. Wine was allowed to macerate for 2 weeks after the completion of fermentation with daily CO2 gassing. Both tanks of wine were drained and pressed on the same day with the free run only used for the experiment. Wines were inoculated for malolactic fermentation, which completed in tank prior to treatment with SO2 and transfer to barrels for aging.

Results

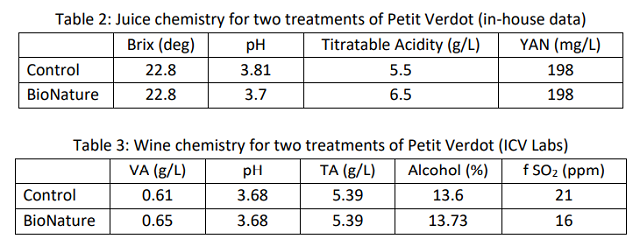

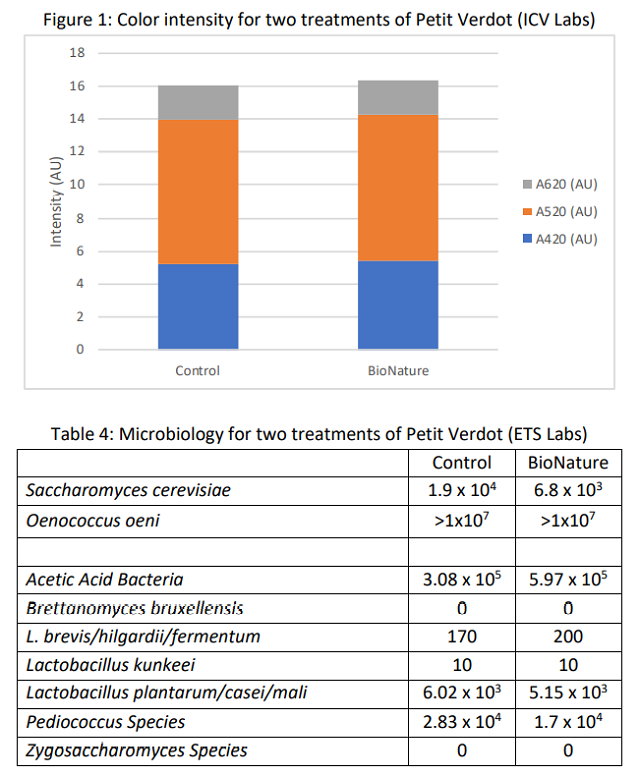

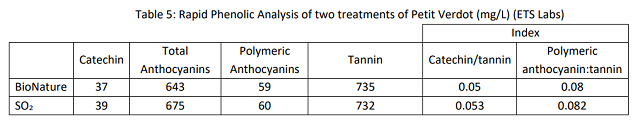

The juice chemistry was very similar between lots (Table 2), as was finished wine chemistry (Table 3). There were no notable differences in volatile acidity or color between lots. Microbial load was also similar in the finished wine (Table 4) with no detectable Brettanomyces in either lot. Both lots had measurable Lactobacillus and Pediococcus populations. Use of SO2 vs. non-Saccharomyces yeast led to no notable change in phenolics (Table 5). The 2019 vintage was one with very little rainfall or disease pressure. In this case, inoculation with Bionature controlled microbial growth as well as 25 mg/L SO2 addition at crush.

References

(1) Chauffour, E. Bioprotection: SO2 Alternatives for Microbial Management in Winemaking.

(2) Jackson, R. S. Wine Science: Principles and Applications, 4 edition.; Academic Press: Amsterdam, 2014.

(3) Barata, A.; Malfeito-Ferreira, M.; Loureiro, V. The Microbial Ecology of Wine Grape Berries. International Journal of Food Microbiology 2012, 153 (3), 243–259.

(4) Wine Microbiology. UC Davis Viticulture and Enology.

(5) Diversity of Wine Yeasts | Viticulture and Enology https://wineserver.ucdavis.edu/industry-info/enology/wine-microbiology/yeast-mold/diversity-wine-yeasts (accessed 2018 -11 -13).

(6) García, M. E. R.; Esteve-Zarzoso, B.; Arroyo, T. Non-Saccharomyces Yeasts: Biotechnological Role for Wine Production; 2016.

(7) Medina, K.; Boido, E.; Dellacassa, E.; Carrau, F. Growth of Non-Saccharomyces Yeasts Affects Nutrient Availability for Saccharomyces Cerevisiae during Wine Fermentation.

(8) Bisson, L. F. Stuck and Sluggish Fermentations. American Journal of Enology and Viticulture 1999, 50 (1), 107–119.

(9) Jolly, N. P.; Varela, C.; Pretorius, I. S. Not Your Ordinary Yeast: Non- Saccharomyces Yeasts in Wine Production Uncovered. FEMS Yeast Res 2014, 14 (2), 215–237.

(10) Vilela, A. Lachancea Thermotolerans, the Non-Saccharomyces Yeast That Reduces the Volatile Acidity of Wines. Fermentation 2018, 4 (3), 56.

(11) Ciani, M.; Domizio, P. Controlled Mixed Culture Fermentation: A New Perspective on the Use of Non- Saccharomyces Yeasts in Winemaking. FEMS Yeast Research.

(12) Ciani, M.; Comitini, F.; Mannazzu, I.; Domizio, P. Controlled Mixed Culture Fermentation: A New Perspective on the Use of Non-Saccharomyces Yeasts in Winemaking. FEMS Yeast Res. 2010, 10 (2), 123–133.

(13) Ndlovu, T.; Divol, B.; Bauer, F. F. Yeast Cell Wall Chitin Reduces Wine Haze Formation. Appl. Environ. Microbiol. 2018, 84 (13), e00668-18.

(14) Ciani, M.; Comitini, F. Yeast Interactions in Multi-Starter Wine Fermentation. Current Opinion in Food Science 1, 1–6.

(15) Villalba, M. L.; Susana Sáez, J.; del Monaco, S.; Lopes, C. A.; Sangorrín, M. P. TdKT, a New Killer Toxin Produced by Torulaspora Delbrueckii Effective against Wine Spoilage Yeasts. International Journal of Food Microbiology 2016, 217, 94–100.

(16) Sadoudi, M.; Rousseaux, S.; David, V.; Alexandre, H.; Tourdot-Maréchal, R. Metschnikowia Pulcherrima Influences the Expression of Genes Involved in PDH Bypass and Glyceropyruvic Fermentation in Saccharomyces Cerevisiae. Front. Microbiol. 2017, 8.

(17) Osborne, J. Yeast Management for Stressful Alcoholic Fermentation, 2019.