Hyperoxidation Fining Trials of Petit Manseng (2016)

Ben Jordan

Early Mountain Vineyards

Summary

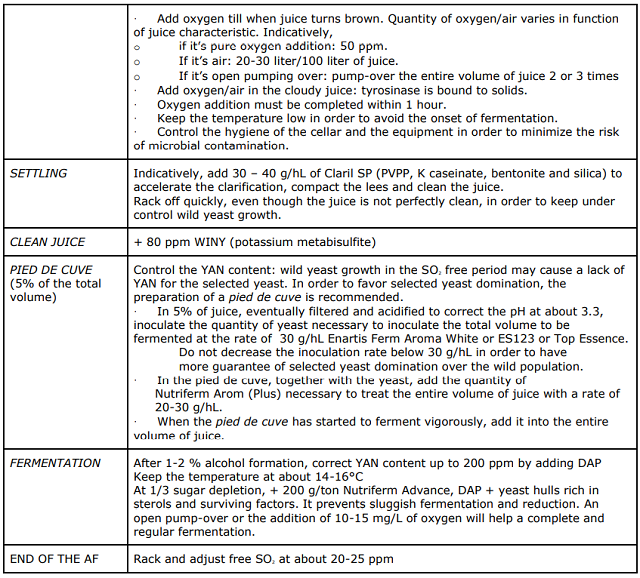

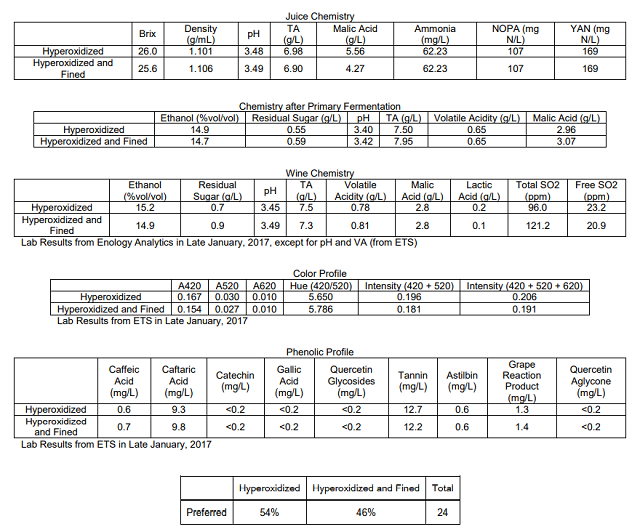

This study examines the effect of adding fining agents to hyperoxidized Petit Manseng juice on the sensory and phenolic characteristics of Petit Manseng. After reducing the temperature to 10-12°C, Petit Manseng juice was hyperoxidized by pumping four volumes of juice over a sump screen, taking about 10 minutes. After this process, juice was very brown and then sulfur dioxide was added at 50ppm. Juice was then split into two vessels, one of which was fined with casein, PVPP, and bentonite to remove solids and phenolic compounds. All other treatments between juices and wines were identical. Overall, no major chemical, color, or phenolic differences were observed between the wines, suggesting that fining juice after hyperoxidation does not do much to alter the color and phenolic properties of the wine. Triangle testing suggests that the wines were significantly different from each other (p<0.001), likely due to a difference in turbidity. No preferences could be seen for one wine over the other. The fined wine had a slight tendency for lower Tropical Fruit and increased Bitterness/Astringency.

Introduction

Skin contact in Petit Manseng wines may pose a viable solution to reducing the acidity found in these grapes. Apart from some benefits such as potential for enhanced aromatic quality, skin contact in white wines can result in wines which are more bitter and phenolic. One option that has been explored to reduce the negative impacts of skin contact is hyperoxidation of juice prior to any form of sulfite or yeast addition. This hyperoxidation is meant to oxidize phenolic compounds in juice so that oxidized phenolic compounds are pulled out of solution during solids precipitation in fermentation. However, the efficacy of hyperoxidation is importantly determined by the initial phenolic content and polyphenol oxidase concentration of the juice, which can vary widely among varieties. Although hyperoxidation is thought to result in lower quality in wine (Singleton et al. 1980; Boulton et al. 1996), others have found that hyperoxidation may have no effect or even positive effects on wine quality (Müller-Späth 1977; Valouyko and Papyakan, 1984; Nagel and Graber 1988; Cheynier et al. 1989). In this study, the effect of hyperoxidation compared to hyperoxidation with juice fining afterwards is compared.

Results and Discussion

Overall, no major chemical, color, or phenolic differences were observed between the wines, suggesting that fining juice after hyperoxidation does not do much to alter the color and phenolic properties of the wine. For the triangle test, of 31 people who answered, 25 people chose the correct wine (81%), showing a statistically significant difference between wines (p<0.001). This was likely due to the difference in turbidity between wines. These wines were voted to have an average degree difference of 4.7 (out of 10), suggesting that the wines were moderately different. In general, there was no preference for one kind of wine over the other. No strong trends could be seen for the wines with the descriptors used in this study. The fined wine had a slight tendency for lower Tropical Fruit and increased Bitterness/Astringency.

Methods

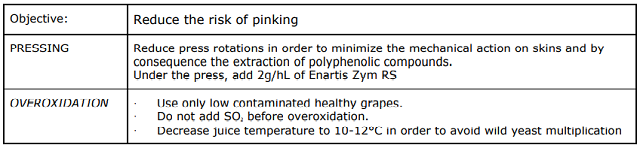

Note: Hyperoxidation protocol adapted from Enartis (attached below for reference).

One block (4.033 tons) of Petit Manseng grapes were harvested on 9/13, stored overnight, and then destemmed, slightly crushed, and pressed on 9/14 into 2 separate but identical fermentation vessels. 52g of Lafazyme Extract were added at pressing, but no sulfur dioxide was added until hyperoxidation was completed. 2100L were pressed, and 450L were taken for the experiment.

The juice temperature was dropped to 10-12°C. The juice was then hyperoxidized by pumping 4 volumes of juice over a sump screen (achieved approximately 30% saturation of dissolved oxygen). The pumpover process took 10 minutes, with a starting dissolved oxygen content of 0.16mg/L, halfway through a content of 1.75mg/L, and at the end a content of 3.45g/mL. At this stage, the juice was very brown, and 50ppm sulfur dioxide was added to the juice which was subsequently split equally into two vessels. One of the two vessels was fined to remove solids and pigment on 9/15 (a mixture of 0.1 g/L casein, 0.15 g/L PVPP, and 0.35 g/L bentonite) whereas the other remained with solids (was unfined). Each lot was then allowed to settle until 9/16, upon which they were both racked to identical barrels.

The juices were then inoculated on 9/17 with Lalvin QA23 yeast (0.25g/L) which was rehydrated with 0.3g/L Go Ferm. On 9/21 Superfood and DAP was added at a rate of 0.15g/L and 0.8g/L, respectively. These were added again on 9/22, with double the amount of DAP. On 10/6 fermentation was stopped with 50ppm sulfur dioxide, and on 12/15 sulfur dioxide was added again.

For the triangle test and preference analysis for the March 15 tasting, anybody who did not answer the form were removed from consideration for both triangle, degree of difference, and preference. Additionally, anybody who answered the triangle test incorrectly were removed from consideration for degree of difference and preference. Additionally, any data points for preference which did not make sense (such as a person ranking a wine and its replicate at most and least preferred, when they correctly guessed the odd wine) were removed.

In order to balance the data set to perform statistical analysis for descriptive analysis on the March 15 tasting, any judge who had not fully completed the descriptive analysis ratings were removed. In order to then make the amount of judges between groups equivalent, one judge from group 1 and group 2 were eliminated. This resulted in a final data set of 3 groups, each with 9 judges (considered as replications within groups, and groups were considered as assessors). Data was analyzed using Panel Check V1.4.2. Because this is not a truly statistical set-up, any results which are found to be statistically significant (p<0.05) will be denoted as a “strong trend” or a “strong tendency,” as opposed to general trends or tendencies. The statistical significance here will ignore any other significant effects or interactions which may confound the results (such as a statistically significant interaction of Judge x Wine confounding a significant result from Wine alone). The descriptors used in this study were Tropical Fruit, Overall Aromatic Intensity, Reduced/Oxidized (as a scale from most reduced to most oxidized), Depth of Flavor, Bitterness/Astringency, and Body.

References

Singleton, V.L., Zaya, J., and Trousdale, E. 1980. White table wine quality and polyphenol composition as affected by must SO2 content and pomace contact time. Am. J. Enol. Vitic. 31:14-20.

Valouyko, G.G. and Papyakan, A.B. 1984. Perfection de la technologie de production de vins blancs de table à la base de l’étude des proprieétés d’oxydation de moût et de vin. Presented at the 3rd Bulgarian Scientific and Technic Conference on Enology. Sofia, Bulgaria.

Müller-Späth, A. 1977. Connaissances nouvelles sur l’influence de l’oxygène en vinification vue sous l’angle de la pratique. Die Weinmirtschaft. 6:1-12.

Nagel, C.W. and Graber, W.R. 1988. Effect of must oxidation on quality of white wines. Am. J. Enol. Vitic. 39:1-4.

Cheynier, V., Rigaud, J., Souquet, J.M., Barillère, J.M., and Moutounet, M. 1989. Effect of pomace contact and hyperoxidation on the phenolic composition and quality of Grenache and Chardonnay wines. Am. J. Enol. Vitic. 40:36-42.

Boulton, R, Singleton, V, Bisson, L, and Kunkee, R. 1996. Principles and Practices of Winemaking. New York: Chapman Hall; 1996.

Enartis Protocol