Comparing chemistry and sensory characteristics of ambient vs. inoculated (CY3079 Scottlabs) fermentations in Chardonnay (2018)

Rachel Stinson Vrooman

Stinson Vineyards

Summary

Long before the Scottlabs Catalogue provided a library of hundreds of yeast strains with known fermentation parameters conveniently available in freeze dried packaging, ambient yeast were doing the work of wine fermentation. There are many known pros and cons to ambient fermentation. The purpose of this experiment was to compare Chardonnay fermented using CY3079 with that using an ambient starter culture. The resulting chemistry of the two wines was nearly identical. The wines were able to be distinguished in a triangle test, with perception of acidity and freshness cited as a cause for discrimination.

Introduction

Long before the Scottlabs Catalogue provided a library of hundreds of yeast strains with known fermentation parameters conveniently available in freeze dried packaging, ambient yeast were doing the work of wine fermentation. Saccharomyces cerevisciae as a species is thought to have been domesticated in ancient Mesopotamia, around the same time vines themselves were domesticated1. This line of fermentative yeast spread around the world along with the grape vines that provided its substrate for fermentation. It was Louis Pasteur who first named S. cerevisciae as the agent of fermentation in 18601. Ever since then, people have been isolating, culturing, selecting and preserving their favorite strains. Though there have been a few genetic bottlenecks leading to rapid, widespread adoption of a single genetic type (such as the evolution of copper resistance when this pesticide was introduced in the vineyard) this species remains very diverse, such that no one strain accurately portrays the whole species1.

The rise of molecular genetic techniques has provided much more detailed understanding of the microbes involved in fermentation, and with this information, we now have greater ability to understand the role of microbial diversity in the outcome of alcoholic fermentations. In recent years, studies have shown that non-Saccharomyces yeast play a large role in the beginning stages of fermentation that can be both positive (producing succinic acid and glycerol, liberating amino acids) and negative (producing acetic acid and ethyl acetate)2. These yeast also compete with Saccharomyces for nutrients and can delay the onset of fermentation. Studies have also shown a diversity of Saccharomyces strains at work within a single fermentation, even when fermentations have been inoculated. However, this diversity is higher in non-inoculated fermentations1,3. Overall microbial diversity has been shown to increase both complexity and intensity of aromatics in non-inoculated fermentations1–3.

Ambient fermentations often start slower and take longer and may have additional nutrient needs due to higher levels of microbial activity. They may also languish near the end of fermentation. Commercial yeast have been bred as “strong fermenters” and winemakers have become accustomed to yeast that can continue to metabolize in the stressful conditions of the end of fermentation. Ambient yeast may or may not be as robust. Ambient fermentation is not recommended for re-starting a stuck fermentation, for use on compromised fruit or “difficult” fermentation conditions such as high Brix, high acid, or other chemistry that may lead yeast to not finish the fermentation. In the end, a balance between diversity and spoilage must be sought.

In practice, many wineries that do not use commercial yeast raise a starter culture that is used for inoculation. The idea is to select for a strain of Saccharomyces that is ambient to the grapes, the vineyard, or the winery. When using a starter culture, a small amount (a bucket or a keg) of crushed grapes or pressed juice is allowed to begin fermenting in a separate vessel. Fermentation is monitored until Brix depletion has reached roughly half and enough alcohol has built up to kill off spoilage organisms. This fermenting culture is then used to inoculate the larger batch. It is important to smell and taste the starter culture prior to addition to the larger lot. If available, a microscope can be used to check for adequate populations of budding Saccharomyces (round) cells. Lemon-shaped (apiculate) cells indicate Klockera, a potential spoilage organism. Addition of SO2 or chitosan into the starter culture or the larger lot will select against non-Saccharomyces microbes. This lessens the risk of spoilage but also lessens diversity of aromatic compounds that can be produced.

Winemakers that rely on spontaneous fermentations do so for a number of reasons. Some feel these provide greater aromatic complexity. Some feel this approach offers a better expression of the grape itself or the terroir in which it was grown. Others feel these better reflect yearly variations in character. However, there is also a greater risk of off odors, long lag periods, and spoilage with spontaneous fermentations. The purpose of this experiment was to compare Chardonnay fermented using CY3079 with that using an ambient starter culture.

Methods

A starter culture for ambient fermentation was prepared 4-5 days prior to harvest. Clean Chardonnay clusters were picked and crushed into a cleaned and sanitized 6-gallon bucket with a removable lid. A single SO2 addition of 30 ppm was made. The container of crushed fruit was kept in the vineyard to limit exposure to commercial yeast in the winery and allow the native yeast fermentation to begin. The temperature of the starter was kept near 26°C by shading or sun exposure. The starter was monitored for Brix depletion and temperature daily, twice per day when fermentation began to move briskly. The starter was oxygenated on day 2 and 3. When Brix reached a level between 8 and 12, pomace in the bucket was strained and the fermenting juice was tasted to ensure a clean start to fermentation (no ethyl acetate or volatile acidity), then used for inoculation.

Fruit was harvested on August 28 then chilled overnight prior to processing. Fruit was lightly crushed and pressed with 50 ppm SO2 and 30 ml/ton Cinn Free. Juice was cold settled overnight then transferred to barrels of similar type (cooper, age, dimensions). Inoculated barrels received an addition of 15 g/hL CY3079 yeast rehydrated in 20 g/hL Superstart Blanc. The other set of barrels received an equal volume of the starter culture (after stirring). Fermentations were monitored twice daily for Brix depletion and temperature. Barrels were placed in the cellar, in the same ambient temperature environment with fermentation temperatures not exceeding 65°F. Sugar (15 g/L), acid (1 g/L tartaric acid, 0.3 g/L malic acid), and Fermaid O were added at 1/3 Brix depletion. After alcoholic fermentation was complete, each lot was allowed to go through malolactic fermentation. Malic depletion was monitored with paper chromatography. SO2 (50 ppm) was added after completion of malolactic fermentation. Wine was aged on lees with stirring and SO2 monitoring.

Sensory analysis was completed by a panel of 28 wine producers. Wines were presented blind in randomly numbered glasses. Tasters were presented with three wines, two of one type and one of another, and asked to identify which wine was different (a triangle test). There were three tasting groups with the unique wine in the triangle test balanced between groups. Tasters were then asked to score each wine on a scale of 0 to 10 for fruit intensity, complexity and Chardonnay varietal character. They were also given open ended questions to describe the wines. Results for the triangle test were analyzed using a one-tailed Z test. Descriptive scores were analyzed using repeated measures ANOVA.

Results

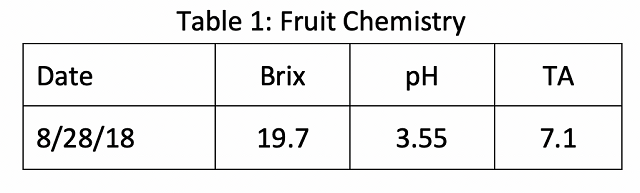

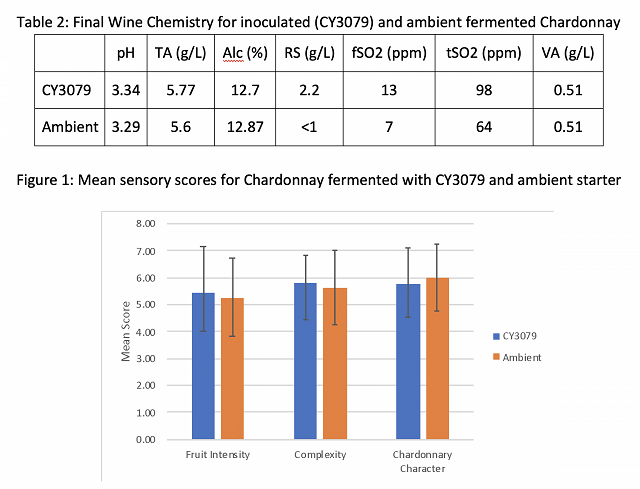

Both treatments received juice from the same press. Juice chemistry can be found in Table 1. There was little difference in final acidity or alcohol production between the wines (Table 2). The ambient fermentation consumed all of the sugar while the inoculated fermentation left 2.2 g/L. Ambient fermentation resulted in less total sulfur, with the same resulting volatile acidity.

In a triangle test of inoculated and ambient fermented wines, 15 out of 28 respondents were able to distinguish which wine was different, indicating the wines were significantly different (Z=2.07, p= 0.02). There were no significant differences in descriptive scores for fruit intensity (F=0.24, p=0.,63), complexity (F=0.13, p=0.72) or Chardonnay varietal character (F=0.14, p=0.71)(Figure 1). Responses from open ended questions indicate a perceived difference in acidity or freshness between the wines with the wine fermented with CY3079 perceived as fresher.

Conclusions

- The basic chemistry of inoculated and ambient fermented wines was very similar.

- Respondents were able to distinguish the wines in a triangle test, with perception of acidity the stated difference for several tasters, despite little difference in measured acidity.

References

(1) Bisson, L. F. Geographic Origin and Diversity of Wine Strains of Saccharomyces. American Journal of Enology and Viticulture 2012, 63 (2), 165–176

(2) Jackson, R. S. Wine Science: Principles and Applications, 4 edition.; Academic Press: Amsterdam, 2014.

(3) Egli, C. M.; Edinger, W. D.; Mitrakul, C. M.; Henick‐Kling, T. Dynamics of Indigenous and Inoculated Yeast Populations and Their Effect on the Sensory Character of Riesling and Chardonnay Wines. Journal of Applied Microbiology 1998, 85 (5), 779–789.