Can aeration be used to promote yeast health without nutrient additions? (2024)

Kirsty Harmon

Blenheim Vineyards

Summary

Complex nutrients like Superfood and Fermaid products contain yeast assimilable nitrogen and “survival factors” (aka sterols), both of which may contribute to fermentation security. For winemakers who want to limit addition of exogenous products, aeration may be used to help yeast produce survival factors. This experiment compared the effects of nutrient addition and aeration on yeast health and fermentation security in Rosé made from Merlot. Juice with low YAN (88 mg/L) was split into two tanks: one received a nutrient addition of 35 g/hL Fermaid O, while the other was aerated by pumpover for 10 minutes at 4° Brix depletion. Both treatments showed similar initial kinetics, but after the first few days, the nutrient-supplemented fermentation progressed more quickly and completed with lower volatile acidity and less browning. The oxygenated fermentation slowed earlier, retained residual fructose, and showed perceptible oxidation, though sulfide levels were slightly lower. These results suggest that while aeration may help yeast tolerate ethanol stress, it was not sufficient to replace nutrient additions under these conditions.

Introduction

In an effort to limit exogenous additions, Kirsty Harmon, the winemaker at Blenheim Vineyards, prefers not use yeast rehydration media or nitrogen supplementation except in Rosé and Sauvignon Blanc, when reductive aromas are likely to occur. In Rosé, nitrogen nutrients are added at 1/3 Brix depletion. Sauvignon Blanc is supplemented only if it is getting reductive, and only if this occurs prior to 14°Brix. In each case, complex nutrient such as Superfood or Fermaid K are used.

Complex nutrients like Superfood and Fermaid products contain yeast assimilable nitrogen and “survival factors” (aka sterols), both of which contribute to fermentation security. Nitrogen is an essential nutrient for yeast proliferation because it is found in the DNA and proteins of cells. In a fermentation inoculated with commercial yeast, the yeast population increases from 106 cells/mL to 108 cells/mL within the first few days of fermentation (before 1/3 Brix drop)1. Nitrogen is essential for building all those cell bodies! Even after cell division is complete, nitrogen is still needed to build proteins that transport sugar across the cell membrane. During fermentation, different versions of sugar transporters are needed depending on the concentration of sugar in the juice. (As early as 1999, genes for 18 different variations of sugar transporting proteins have been identified in Saccharomyces cerevisciae!2) As sugar becomes more scarce toward the end of fermentation, new transporters with higher affinity are needed, and nitrogen is needed to build them. Unfortunately, by that time, high ethanol in the fermenting wine inhibits the translocation of nitrogen containing compounds into the cell, so the cell needs to stockpile these compounds early, before ethanol gets too high2. This dual need for nitrogen (1) at the beginning of fermentation to build yeast cells and (2) throughout fermentation to turnover sugar transporting proteins is the basis for the manufacturer recommended additions at 2-3° Brix drop and before 1/3 Brix depletion.

Nitrogen alone is not enough to build an efficient sugar uptake apparatus capable of completing fermentation in yeast cells. As ethanol builds up during fermentation, it has a complex impact on cell membrane processes, including changes in fluidity and in the ability of proteins to transport sugar and other nutrients through the membrane2. In addition to changes in the sugar transporters themselves, cells respond to rising alcohol with the production of unsaturated fatty acids and ergosterol2. Unfortunately, sterols and fatty acids cannot be synthesized by yeast when there is no oxygen is present, so they must be taken up from the fermenting juice2. These may be supplied through juice solids or enological additives, and can improve fermentation kinetics, reduce the risk of sluggish or stuck fermentations, and enhance yeast nitrogen assimilation3. Maintaining yeast health with adequate sterols also helps reduce yeast stress, lowering the production of acetic acid and acetaldehyde4.

Another option for building sterols in yeast cell membranes may be the aeration of fermenting juice at or near 1/3 Brix depletion. It is the low oxygen environment of fermentation that inhibits yeast from building their own unsaturated fatty acids and sterols. Providing oxygen during fermentation increases sterol content and decreases duration of fermentation5. However, addition of air may also encourage the growth of some microbes (Acetobacter, non-Sacc yeasts6) as well as shift ester production to higher alcohols (and less fruity expressions)7. In studies of aeration during Chardonnay fermentation in 2019 and 2020, the AWRI found that even low rates of aeration, causing no difference in DO, decreased fermentation time by half6,8. Though fermentation with high rates of addition (1.6L/min/kL for 2.5 hours) led to increases in volatile acidity (acetic acid and ethyl acetate), lower rate (0.55L/min/kL for 48 hours) did not8. Aeration may also lead to shifts in the microbial community. In non-inoculated fermentations, early aeration increased the population of non-Saccharomyces yeast, while aeration of inoculated populations benefited Saccharomyces6.

In 2023, Kirsty tested the impact of aeration vs. nutrient addition at 1/3 Brix depletion in the fermentation of Rosé from Cabernet Franc that began fermentation with YAN of 45 mg/L. Despite a very low YAN, there was no difference in fermentation kinetics, acetic acid accumulation, or sulfides (as measured by ETS) between the wines. Kirsty and Joy tasted these wines in the spring and felt they were not different, so they were not presented at a sensory session. The purpose of this experiment was repeat the experiment comparing yeast supplementation with exogenous nutrients vs. aeration in promoting yeast health, fermentation security and aromatic expression. This is a good example of an experiment where “no” might be an important answer.

Methods

Merlot fruit was hand harvested on 9/11/24, chilled overnight, then pressed to a single tank for Rosé. Juice was chaptalized with 27 g/L sugar to increase Brix by 1.7 degrees. After chaptalization and mixing, the juice was split into two tanks for fermentation with approximately 450 L per tank. After cold settling and racking, juice was inoculated with 15 g/hL Rhone 4600 yeast rehydrated in water. Tank temperature was set at 60°F. Brix depletion and temperature were monitored daily. After depletion of 4° Brix, one tank received an addition of 35 g/hL Fermaid O while the other tank was aerated. Aeration was accomplished by pumping over for 10 minutes. Dissolved oxygen was measured in both tanks before and after addition of nutrients or air. No other additions were made.

Results

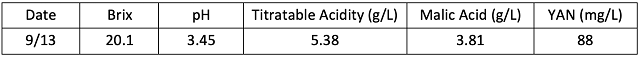

At the start of fermentation, the juice had a YAN of 88 mg/L and a sugar content of 20.1° Brix (after chaptalization)(Table 1). Rhone 4600 is a yeast strain with low nutrient requirements, so the ScottLabs nutrient calculator recommends a YAN target of 150 mg/L to ensure fermentation security. This made the lot ideal for nutrient experimentation.

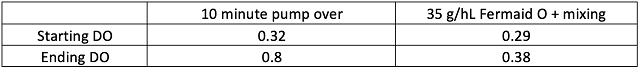

According to ScottLabs recommendations, the full nutrient addition plan would involve adding 20 g/hL of Fermaid O at a 2-3° Brix drop, followed by an additional 40 g/hL when the Brix drops by 1/3. In this experiment, one fermentation received 35 g/hL of Fermaid O at a 4° Brix drop, while the other received 10 minutes of aeration. Juice was aerated with a pumpover for 10 minutes with the goal of providing enough oxygen for yeast cell membrane development while avoiding juice oxidation (indicated by an increase in dissolved oxygen) or feeding spoilage organisms (that would result in production of acetic acid and ethyl acetate). Both nutrient addition and intentional aeration led to a small change in dissolved oxygen, but the aeration resulted in higher DO (Table 2). As a reference, dissolved oxygen of <0.5 mg/L is desired for white wines at bottling. A dissolved oxygen of 0.8 mg/L indicates oxygen was available to yeast cells.

Table 1: Juice Chemistry after chaptalization (Imbibe Solutions)

Table 2: Dissolved oxygen before and after fermentation additions (in-house data)

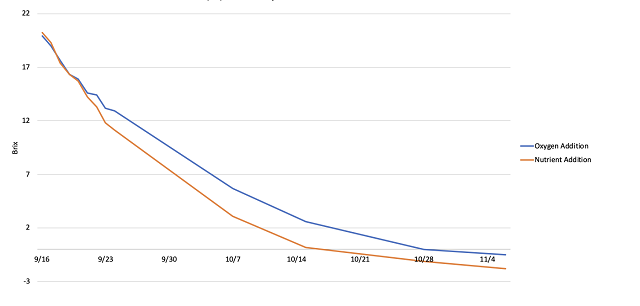

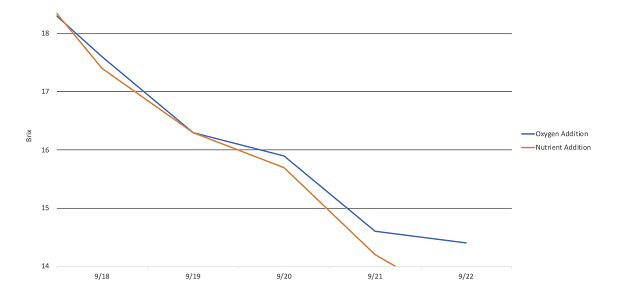

Fermentation began in a robust manner; however, kinetics of the fermentation began to level off slightly on 9/19 (Figure 1). Additions of nitrogen nutrients or oxygen were made on 9/20. Both fermentations benefited from additions with the nitrogen addition leading to a steeper increase in fermentation rate than the oxygen addition (Figure 1b). The difference in fermentation rate persisted through the rest of the fermentation, with the oxygen treated fermentation slowing down much sooner that the nitrogen treated fermentation.

Figure 1: Fermentation kinetics with aeration and nutrient addition (in-house data)

(a) Full span of fermentation

(b) Detailed kinetics of the first 1/3 of fermentation. Nutrient addition and oxygenation were done on 9/20

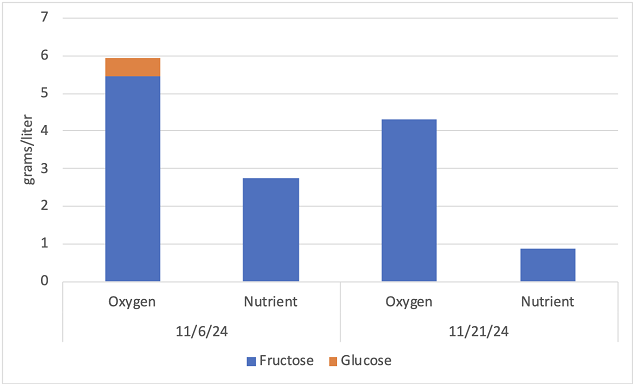

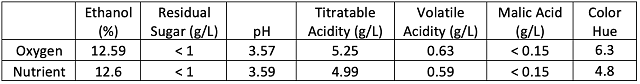

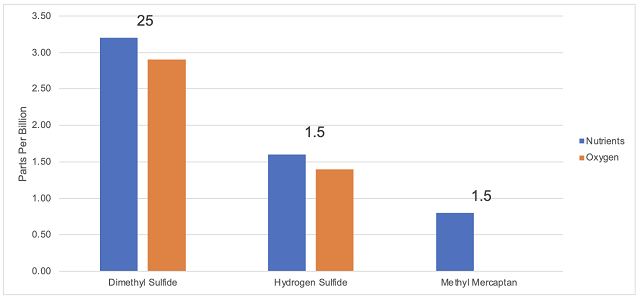

In November, both wines still had a small amount of residual sugar (Figure 2). The wine that received nutrient addition was able to consume all the glucose and much of the fructose by the end of November, while the oxygenated wine still had above 4 g/L fructose on 11/21/24 (Figure 2). The wine that received nitrogen supplementation during fermentation completed fermentation with lower volatile acidity and lower color hue (a measure of browning)(Table 3). The oxygenated fermentation produced wine with slightly lower sulfides, but all values in both wines were below threshold values (Figure 3). Sensory analysis was not done on these wines, as there was perceptible oxidation in the oxygen treated wine that would have obscured other aromatic indicators.

Figure 2: Residual sugar in two treatments of Rosé (in-house data)

Table 3: Post fermentation wine chemistry for two treatments of Rosé (ICV labs, 12/23/24)

In this case, a single aeration shortly after the beginning of fermentation was not sufficient to prevent sluggish fermentation. Though aeration may help yeast with alcohol tolerance and may even increase the uptake of nitrogen from the medium, nitrogen is still needed in sufficient concentration to replenish glucose transport. A different aeration scheme may also be needed. In the AWRI study, a smaller flow rate of oxygen over longer time resulted in better fermentation kinetics than shorter term additions of higher dose oxygen8.

Figure 3: Sulfides present in two treatments of Rosé (ETS Labs, 12/26/24). Threshold values are listed in endcaps

References

(1) Bisson, L. F.; Butzke, C. E. Diagnosis and Rectification of Stuck and Sluggish Fermentations. Am J Enol Vitic. 2000, 51 (2), 168–177.

(2) Bisson, L. F. Stuck and Sluggish Fermentations. American Journal of Enology and Viticulture 1999, 50 (1), 107–119.

(3) Casalta, E.; Salmon, J.-M.; Picou, C.; Sablayrolles, J.-M. Grape Solids: Lipid Composition and Role during Alcoholic Fermentation under Enological Conditions. Am J Enol Vitic. 2019, 70 (2), 147–154.

(4) Nicolini, G.; Moser, S.; Román, T.; Mazzi, E.; Larcher, R. Effect of Juice Turbidity on Fermentative Volatile Compounds in White Wines.

(5) Larue, F.; Lafon-Lafourcade, S.; Ribereau-Gayon, P. Relationship Between the Sterol Content of Yeast Cells and Their Fermentation Activity in Grape Must. Appl Environ Microbiol 1980, 39 (4), 808–811.

(6) Varela, C.; Cuijvers, K.; Van Den Heuvel, S.; Solomon, M.; Borneman, A.; Schmidt, S. What Happens When You Aerate a Wild Chardonnay Ferment? (AWRI) Technical Review 2022, 258, 13–20.

(7) Mauricio, J. C.; Moreno, J.; Zea, L.; Ortega, J. M.; Medina, M. The Effects of Grape Must Fermentation Conditions on Volatile Alcohols and Esters Formed bySaccharomyces Cerevisiae. J. Sci. Food Agric. 1997, 75 (2), 155–160.

(8) Schnidt, S. Aerating Ferments: Why Aeration Is Useful and How You Can Do It. https://www.youtube.com/watch?v=w0QYC4JXoBM&list=PL7Z5GkvVSSxzWQHSgDPCIwdwPEWDcc6cA&index=9.