Using Cold Stabilization of Red Wine Press Fraction to Reduce K+ and pH During Aging in Petit Verdot

Matthieu Finot

King Family Vineyards

Summary

Petit Verdot is a popular red grape variety in Virginia due to its ability to ripen in humid conditions and make bold, powerful, ageable wines. However, this variety has the tendency to finish fermentation with high pH levels, leading to the need for high levels of acid addition and potential for spoilage during aging. It is thought the high pH of Petit Verdot is due to high levels of potassium released from skins during fermentation. In this study, press fraction Petit Verdot wine was cold stabilized prior to aging to improve efficacy of tartaric acid additions. Cold stabilized wine had lower pH, lower potassium, and higher TA throughout aging without showing signs of oxidation. Further studies are planned to repeat and expand on this approach as a solution for high pH red wines in Virginia.

Introduction

Petite Verdot is a native of Southern France, and a minor player in Bordeaux blends1,2, but often takes center stage in Virginia3. It is the third most common red variety grown in Virginia4, bottled both as a varietal wine and also as a notable contributor to Meritage blends. Petit Verdot provides power, color, tannin, and perception of ripeness, and often fills the same space on the tasting bar as Cabernet Sauvignon in other regions3. In the vineyard, Petit Verdot has small berries and loose clusters, allowing it to fully ripen with less rot our humid climate.1 However, in the winery, Petit Verdot often finishes fermentation with pH values above 4.0, leading to potential for microbial spoilage during long aging in the cellar.

The likely cause of high pH in finished Petit Verdot is excess potassium in the grapes. Throughout fermentation, potassium is released and complexes with tartaric acid to form potassium bitartrate (KHT). When in excess, KHT can form crystals and precipitate, leaving the finished wine with higher pH and lower acidity. Common solutions to making red wine with high potassium fruit involve large, early additions of tartaric acid5, essentially a form of potassium fining. However, tartaric acid is expensive, and high acid addition can have sensory consequences. Potassium can also be removed by cation exchange. Equipment companies have developed this technology in large machinery capable of running several thousand liters of wine per hour, however, these machines are costly and beyond the reach of most small wineries. Another alternative is the removal of potassium through tartrate stabilization, followed by tartaric addition at lower rate and higher return.

At King Family, press fraction and free run Petit Verdot wines are combined after pressing, then acidulated before aging. It is thought that the press fraction wine contains a higher proportion of potassium than free run, due to lower pH values and less skin influence. The purpose of this investigation was to explore the removal of potassium from press fraction wine by cold stabilization prior to blending into the free run wine with the aim of improved acid stability during aging.

Methods

Grapes were hand harvested from the Crown Orchard Vineyard in Batesville, Virginia and refrigerated overnight. The following day, grapes were destemmed to temperature-controlled fermentation tanks with the addition of 12g/ton SO2. Must was inoculated with 12 g/hL BM4x4 yeast (Scottlabs) two days after destemming. The following day, 1.5 g/L tartaric acid was added. Fermoplus Premier Cru (AEB) was added on the fifth day of fermentation. Cap management (pumpovers) occurred twice per day. The fermentation tank was drained and pressed after 23 days of maceration. The press fraction was kept separate from the free run.

A total of 4156L of wine was produced from this lot; 3200L of free run and 850L of press fraction. The day after draining and pressing, both free run and press fraction tanks were split into two tanks. Both free run tanks received 1.5 g/L tartaric acid. For the control lot, free run and press fraction were combined and racked to barrel for malolactic fermentation. The remaining press fraction was cold stabilized in a 1000 L tank with a cold plate on one side for 8 days. After cold stabilization, this press fraction was combined with free run wine at the same proportion as control and transferred to barrels for aging. Malolactic fermentation was confirmed complete two weeks later. After completion of malolactic fermentation, an additional 1.5 g/L tartaric acid was added to both treatment and control barrels along with 66ppm SO2 and 3 g/hL Stab Micro (Enartis).

Results

Petit Verdot was harvested with a juice pH of 3.86. Wine completed fermentation with alcohol of 13.93%, malic acid <0.15 g/L, and glucose/fructose <1.0 g/L. Volatile acidity for both lots was within 0.03 g/L and free SO2 was nearly the same (within 10 ppm) at each sampling event.

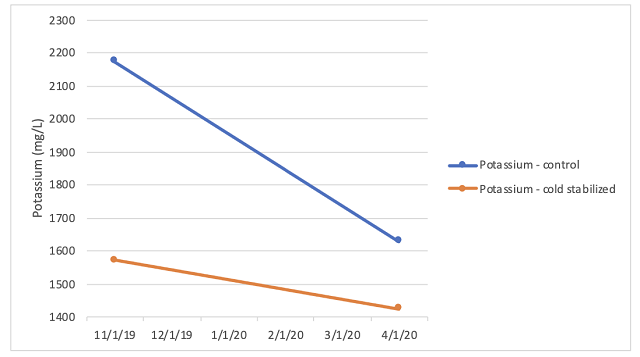

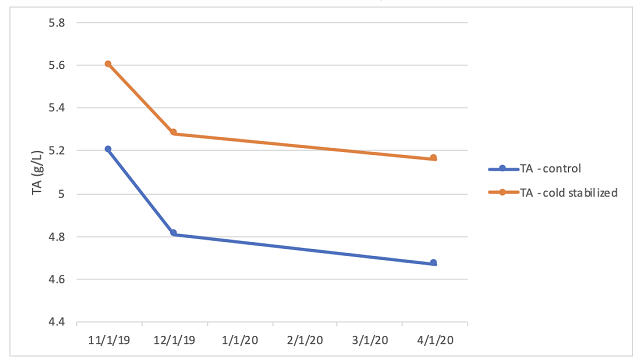

The primary concern was the efficacy of acid addition and the change in pH during aging. Control wine had higher pH at each sampling event with the difference immediately apparent upon cold stabilization (Figure 1). Potassium was measured in November with in-house analysis and in May by ICV labs. For each sampling event, potassium was higher in the control wine than the treatment wine (Figure 2). Titratable acidity was higher for cold stabilized wine than control wine at each sampling event (Figure 3). Together, these indicate that the cold stabilization of the press fraction decreased potassium levels, allowing better retention of tartaric acid and lower pH levels through aging.

One concern with cold stabilization is the potential for oxidation. Hue is the ratio of A420/A520. The absorbance at 420nm indicates the yellow portion of the spectrum while absorbance at 520nm indicates the red portion of the spectrum. Oxidation would be evident by higher hue, meaning, more yellow vs. red. In this case, the cold stabilized wine has slightly lower hue, indicating oxidation did not occur in this case (Figure 4).

Future work

If repeatable, the possibility of using cold stabilization of press fraction wine to improve the pH and acid retention in Petit Verdot could have tremendous impact on wine quality and cost of production in Virginia. In 2020, this study will be repeated and expanded. Additional steps to the work will include the following:

- After pressing, pH will be measured, an acid trial will be done, and tartaric acid will be added to the press fraction to achieve a target pH less than 3.6. This may be a large addition given the expected pH of press fraction Petit Verdot. However, acidulation to this pH will shift the equilibrium in solution so that the bitartrate precipitated out will be replaced from the tartaric acid portion of the equilibrium rather than the tartrate anion portion6.

- Conductivity will be measured for free run and press fraction, before and after cold stabilization.

- The cold stabilization will be seeded with cream of tartar crystals (Zoecklein et al 1995 recommends 4 g/L with “adequate mixing”)6 to speed the process, maximizing the effects of precipitation while minimizing potential for oxidation.

- Cold stabilized press fraction will be racked off tartrate crystals when cold.

- pH (and potentially potassium) will be monitored for each barrel in the lot at least three times during aging (before pH adjustment at the end of malolactic fermentation, in the winter, at the end of the aging period).

- The experiment will be conducted on at least two lots of Petit Verdot, if there is sufficient fruit available.

Figure 1: pH during aging for two treatments of Petit Verdot (in-house data and ICV labs). Tartaric acid (1.5 g/L) was added after the 11/1 sampling event.

Figure 2: Potassium during aging for two treatments of Petit Verdot (in-house data and ICV labs)

Figure 3: Titratable acidity (g/L) during aging for two treatments of Petit Verdot (in-house data and ICV labs)

Figure 4: Hue (A420/A520) for two treatments of Petit Verdot (ICV labs)

References

(1) Wolf, T. K. Wine Grape Production Guide for Eastern North America; Plant and Life Sciences Publishing: Ithaca, New York, 2008.

(2) Robinson, J. The Oxford Companion to Wine, Third Edition.; Oxford University Press: Oxford, 2006.

(3) Carrie, D. Two Unsung Grapes Putting Virginia Wine on the Map. Wine Enthusiast. 2018.

(4) SMS Research Advisors. 2019 Virginia Commercial Grape Report. 2020.

(5) Gardner, D. Making (Red) Wine from Fruit High in Potassium. Penn State Extension Wine & Grapes U., 2016.

(6) Zoecklein, B.; Fugelsang, K. C.; Gump, B. H.; Nury, F. S. Wine Analysis and Production; Springer: New York, 1995.