Comparing protocols for building body and structure post-fermentation (2018)

Matthieu Finot

King Family Vineyards

Summary

Due to the rain experienced during the 2018 harvest, many red wines were harvested early and pressed early. Wines made this way can seem thin in the mid palate and lack structure. Many companies sell products that are advertised to plump the mid palate and add structure to the wine. After harvest, representatives from several enological supply companies were contacted and asked to develop a protocol to address thin mid-palate and limited structure using their products. For each manufacturer, one yeast lees/mannoprotein product and one tannin product were added to the same Malbec wine. There were not chemical differences after aging. Sensory results were mixed, with the AEB products generally preferred and the Enartis products generally not preferred.

Introduction

Due to the rain experienced during the 2018 harvest, many red wines were harvested early and pressed early. Wines made this way can seem thin in the mid palate and lack structure. Many companies sell products that are advertised to plump the mid palate and add structure to the wine. This study is intended to compare these products for sensory impacts and cost. Two categories of products were tested: lees autolysate/mannoproteins and tannins.

Mannoproteins

One of the most common tools in the winery for the addition of body/volume during élevage is the use of yeast lees1. During aging, yeast lees can add to the perception of body, reduce the perception of astringency, and help protect wine from oxidation. Yeast lees can originate from the fermentation, be added from other fermentations, or be purchased from an enological company.

Wine body comes in part from polysaccharides1. Polysaccharides become more extractable as grapes ripen, so in years where grapes are underripe (such as 2018 in Virginia), the initial extraction of grape polysaccharides can be low, further diminishing the body of the wine1.

Yeast contribute the majority of the polysaccharides in wine. Yeast cell walls are made up of mannoproteins, a complex of peptides and the polysaccharides mannan and B-glucan. During fermentation and after cell death, the enzyme B-1,3-glucanase releases these polysaccharides from their protein partner, increasing the polysaccharides in the wine 1–3. The overall amount and type of polysaccharides produced by the yeast depends on the yeast strain as well as the conditions of growth.

Practically, sur lies maturation (the aging of wine on yeast cells), is employed fairly extensively worldwide. The general practice includes 3-6 months of contact with lees with periodic stirring. During this time, dead and dying cells autolyze in a staged breakdown of the yeast1. Sur Lies élevage can be done on lees from the primary fermentation or using added lees from other fermentations. Some have used lees from finished white wine fermentations, others have added dry yeast4. If taken from primary fermentation, Zoecklein (2005)5 makes the distinction between heavy lees and light lees. Heavy lees are those that settle out in the first 24 hours and can contain unwanted materials such as pulp and tartrates while light lees are those still present in solution after 24 hours. The light lees contain living and dead cells and are the desirable portion for sur lie maturation.

Several commercial products are available to provide sources of yeast mannoproteins if endogenous sources are not available. These include activated dry yeast, inactivated yeast hulls rich in mannoproteins, mannoproteins already isolated from yeast, and purified polysaccharides from yeast as well as other sources. Gum Arabic is a polysaccharide from gum trees that is often used for this purpose6. Isolated B-1,3-glucanase is also commercially available to speed up autolysis. Each product has different efficacy, price point, and time required for activity, so care should be taken in choosing the product that will provide the desired effect(s) in the time available. Several WRE trials have been done using lees aging in white and red wines. Results for these trials can be found on the Winemakers Research Exchange website (http://www.winemakersresearchexchange.com). Laffort also organized a series of trials with its version of the B-1,3-glucanase enzyme in 20167.

Tannins and Structure

Another important element of wine balance comes from tannins, as seen in in Zoecklein’s equation for palate balance8:

Sweet ↔ Acid and Phenols

Ribereau-Gayon and Peynaud (1997)9 also included tannins in their suppleness index:

Suppleness= Alcoholic degree – (total acidity + tannin level).

By both of these equations we see that some tannic astringency is needed to balance the sweetness that comes from fruit and alcohol in wine. However, tannins are a diverse group of molecules. Refined tannins will give structure and weight to the wine without harsh astringency, contributing to the perception of body as well. Less refined tannins can be harsh and shift the equation too far to the left, leaving the wine unbalanced. Sometimes the best approach to unrefined tannins is to add more tannin to increased polymerization and decrease perception of astringency6.

According to Jackson (2014)1, tannins are “polymeric phenolic compounds that can tan (precipitate proteins in) leather; in wine they contribute to bitter and astringent sensations, promote color stability, and are potent antioxidants”. During fermentation, the tannins are the slowest portion of the phenolics to accumulate, requiring time spent on the skins and seeds for full extraction1. Many of the wines in Virginia in 2018 were made with limited maceration times to avoid extracting harsh tannins and underripe flavors, and to avoid microbial spoilage. Pressing early may lead to lack of structure in the wine or leave the wine with harsh (less polymerized) tannins.

In addition to adding structure to the wine, there are other reasons to consider the addition of tannins. Tannins bind to anthocyanin molecules, stabilizing color, and bind oxygen, acting as an anti-oxidant. They also bind aldehydes, allowing for recovery of slightly oxidized wines. Under the right circumstances, tannin can react with oxygen as part of a polymerization reaction that recycles the oxygen-reactive portion of the molecules, providing long term antioxidant protection for the wine1.

Types of tannins (how to decipher the catalogue)

Tannins in wine can come from many sources including grape skins, grape seed, and oak. Different types of tannins will have different sensory effects based on source, chemistry, and the degree of polymerization.

Condensed tannins (aka procyanidins) come from grape seeds and grape skins. Chemically, these are made up of catechin and epicatechin subunits that can form long chain polymers. Skins tend to have more polymerized forms (longer chains) while seeds tend to have more monomeric forms (individual subunits) that eventually polymerize in the wine. As a group, condensed tannins provide the majority of the bitter and astringent flavor of the wine and also complex with anthocyanins. Monomeric catechins contribute to bitter flavor. When these subunits polymerize, they contribute rough, grainy, puckery, dry, dusty, and silky textures. It is the polymerized form that gives weight and structure to the wine1,6.

Hydrolysable tannins come primarily from oak (though some come from grape seeds) and are made up of subunits of ellagic and gallic acid and their esters, combined with glucose. Hydolyzable tannins make up 10% of the heartwood of oak trees and perform an antimicrobial function for the tree, and for the wine. In the acidic conditions of wine, these tannins are broken up into their component parts. The esters of ellagic acid may serve as copigments for anthocyanins, helping to stabilize color in the short term, allowing time for more permanent bonds to form with condensed tannins. They are also readily oxidized, which means they act as antioxidants in wine. These tannins form complexes with proteins, which provides an antioxidant function in juice, but also means they are very astringent on the palate, as they also bind salivary proteins1,6.

Both categories of tannins are sold as enological products. These can be sourced from grapes and oak, but also from gall nuts (gallic acid), chestnuts (ellagic tannin) and exotic wood (proanthocyanidins)(6). Enological tannins can be used at several different steps of winemaking from crusher to bottle, to achieve any of the functions of tannins (antioxidant, antioxidasic, protein fining, redox regulation, color stabilization, balancing mouthfeel). When considering addition of a purchased product, it is important to be aware of the type and purpose of the product before addition. Other things to consider include:

- The amount of time the product needs to integrate. Some products are meant for aging, some are meant for fine tuning prior to bottling. Determining your plan early gives you the largest range of options for intervention.

- A combination of products does a better job than one product alone.

- Do bench trials prior to addition. Due to the lighter body of the 2018 wines, the lower rates of addition may be all you need.

- Work with the company representative to choose the right products for your situation. Send him/her a sample of your wine for better context. Manufacturers will often send sample products to do bench trials to help you determine which is the best product.

The purpose of this study is to compare several protocols and products used post fermentation to build body and structure in Merlot.

Methods

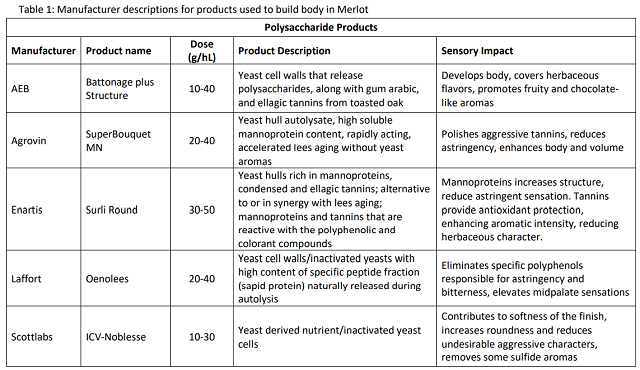

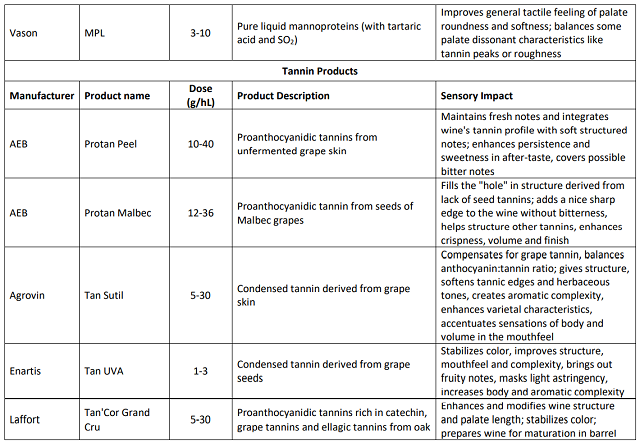

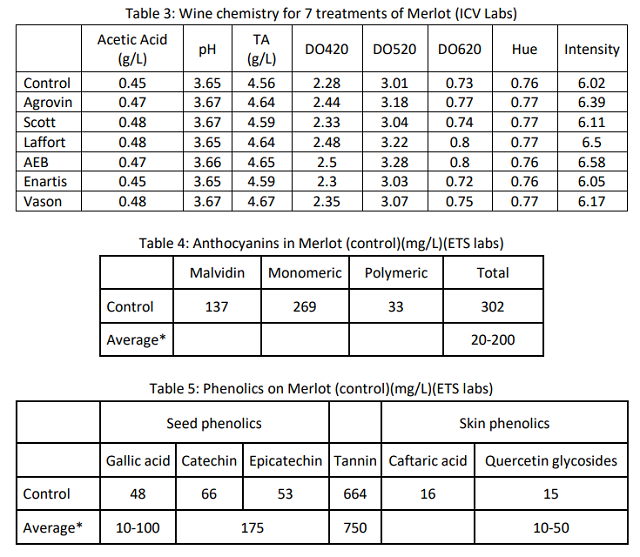

After harvest, representatives from several enological supply companies were contacted and asked to develop a protocol to address thin mid-palate and limited structure using their products. Among the options offered, a general protocol of lees/mannoprotein addition and tannin addition was adopted for each company. An effort was made to choose comparable products from each manufacturer, or to make a close substitution in overall activity if no comparable product was found. Company representatives were consulted for the order and timing of additions as well as recommendations for specific products. Additions began in the early part of 2019, allowing for several months of product integration prior to sensory analysis. Table 1 contains a description of the source and manufacturer’s description of each of the products used in this study while Table 2 contains doses used and cost per barrel for each product at that dose. Additional information on each product is available from the manufacturer.

All additions were made to the same 2018 Merlot wine. Wine was racked to barrel prior to malolactic fermentation. After completion of malolactic fermentation, wine was treated with SO2. Additions were made on the basis of manufacturer’s recommended time frame relative to the date of the sensory session. One control barrel was kept without additional products. Table 2 outlines the additions made to each barrel. Samples for sensory analysis were collected on May 13.

Sensory analysis was completed by a panel of 21 wine producers. Wines were presented blind in randomly numbered glasses. Tasters were presented with seven wines; one labeled as control and the others coded. There were three tasting groups in which wines were presented in different order to avoid order effects. Tasters were asked to score if the numbered wine was better or worse than the control; in essence, did the additions improve the wine?

In a second question, respondents were also asked to write the number or numbers of the wine(s) they liked the best, and the wine(s) they liked the least.

Results

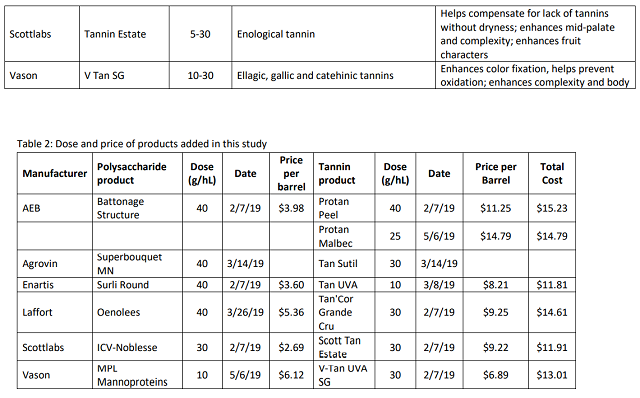

There was very little difference in cost among product when dose rates were taken into consideration (Table 2). Analysis of the control wine reveals this is a wine with average base chemistry and phenolics with slightly lower than average seed phenolics and tannins (Tables 3-5). As expected, there were no notable differences in acetic acid, pH or TA with additions (Table 3). There were small differences in color intensity with treatment (Table 3). Addition of both lees and tannins may have an effect on color, but they offset; the presence of lees may fine out color while the presence of tannin may help to fix color.

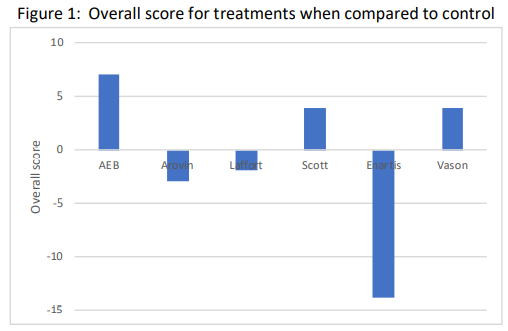

Two questions were used to assess sensory effects of these treatments. In the first, respondents were asked to score the wine as better or worse relative to the control (which was marked). In this case, a treatment was given a +1 if it was scored as better than control and a -1 if it was scored worse than control. Each treatment received both positive and negative marks, indicating there was not consensus as to the benefit of the treatment. When all marks were totaled, the AEB treatment was the most positive (+7) while the Enartis treatment was the most negative (-14)(Figure 1). When all treatments were taken as a whole, the sum was negative, indicating treatment was as often detrimental to the wine as helpful.

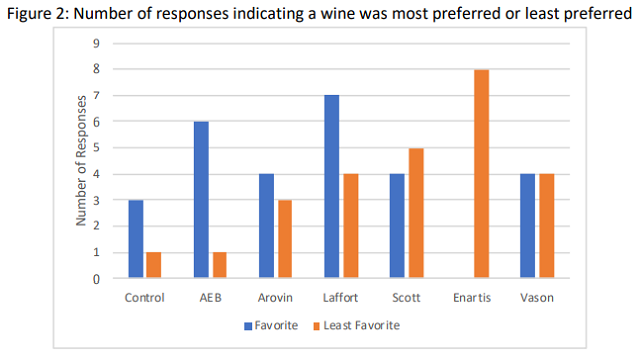

Respondents were also asked to list the coded number of the wine or wine they least or most preferred. This was an attempt to ascertain the magnitude of “better” or “worse” caused by the treatment. All but one treatment was chosen as both most preferred and least preferred at least once (Figure 2). The sole exception was the Enartis treatment, which was never most preferred. The Laffort wine was most likely to be most preferred while the Enartis wine was the most likely to be least preferred. It is notable that some respondents chose the control as most or least preferred, as this was not an obvious choice given the phrasing of the question. Three people felt the control was the best wine.

It is important to state that the products used may be appropriately applied other wines even if they were not preferred on this wine. Also, only a single concentration of product was used in each case. Concentration effects can cause a big difference in whether an addition is considered pleasant and helpful or harsh and detrimental. In essence, this trial underlines the need to do bench trials prior to addition of products. Even if a product worked well at a given concentration in a previous wine, the matrix of the wine is different every time.

Conclusions

- There was no change in general chemistry of the wines with addition of enological products.

- Additions of AEB products Battonage Structure, Protan Peel and Protan Malbec were most preferred while additions of Enartis products were least preferred.

- Overall impressions of the products varied greatly among tasters.

- Some respondents preferred control to any product addition.

- Concentration effects likely played a role in the outcomes. Bench trials should always be done to determine the correct concentration of any addition.

References

(1) Jackson, R. S. Wine Science: Principles and Applications, 4th edition.; Academic Press: Amsterdam, 2014.

(2) Dharmadhikari, M. Yeast Autolysis* https://www.extension.iastate.edu/wine/yeast-autolysis (accessed Dec 24, 2019).

(3) Zoecklein, B. W. The Nature of Wine Lees. Enology Notes No. 162.

(4) Zoecklein, B. Yeast Fining. Enology Notes 2004, No. 85.

(5) Zoecklein, B. Lees Management. Enology Notes 2005, No. 106.

(6) Chauffour, E. Understanding Wine Mouthfeel: The Art of Winemaking.

(7) Report | ARC by Laffort.

(8) Zoecklein, B. W. Enological Tannins. Enology Notes 2005, No. 103.

(9) Peynaud, E. The Taste of Wine: The Art and Science of Wine Appreciation; The Wine Appreciation Guild LTD: San Francisco, California, 1987.