Whole Cluster Fermentations: 3 Fractions, 2 Fermentations

Joy Ting

Dec 2020

Whole Cluster Fermentations: 3 Fractions, 2 Fermentations

Interest in whole cluster fermentation might be trendy, but the technique itself is not new. Crushing and destemming of grapes was only made possible by the invention of efficient crusher/destemmers in the 19thCentury1. Reports from Champagne in the 19th Century document a full week between harvest and processing, indicating that intracellular fermentation, one aspect of whole cluster inclusion, was widespread and descriptions of winemaking from Bordeaux from this time indicate whole clusters were regularly included1.. Even with the advent of destemmers, inclusion of at least a portion of whole clusters has remained a part of winemaking in many Old World regions such as Beaujolais, Rioja and Georgia2 and is currently utilized around the world in regions such as Burgundy, the Rhone, Australia, and California1,3. Carbonic maceration, a specific technique using 100% whole clusters, was invented by Flanzy in 1934 after a failed experiment in preserving grapes. Flanzy’s work (and that of many others) provided research into the chemistry of grape autofermentation, shedding light on the production of the distinctive flavors and aromas found in whole cluster fermentations used throughout the ages1,2.

Wines produced from whole cluster fermentations are characterized by distinct aromas and flavors of kirsch, cherry, strawberry and raspberry1. They are often lighter in body and color than traditional fermentations, though not always, and can have herbal qualities and rustic tannin structure. The overall sensory impact of using whole clusters is influenced by many factors, including the proportion of whole clusters included, the variety and the ripeness of the fruit. In his reflection on whole clusters, Jamie Goode cites winemakers using whole cluster for “greater complexity and silkier tannins”, “to add freshness”, for their “fragrance and perfume”, and ability to “add strength and firmness to the tannins” while others avoid whole clusters because they think they “dull the fruit”, make the wine “too herbal”, or give it a “mulch/compost character”3. Goode’s own assessment is that the move to include clusters is in line with a trend toward “elegance over power”3.

The First Fermentation

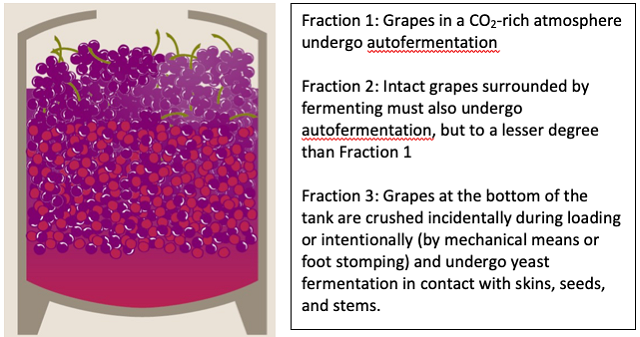

In any whole cluster fermentation, grapes may be found in three different environments (Figure 1); the proportion of grapes in each greatly influences the sensory characteristics of the resulting wine. Some grapes are intact clusters in a CO2-rich atmosphere, and initially experience autofermentation (Fraction 1). Some grapes will be crushed at the bottom of the tank where they are subject to alcoholic fermentation by yeast (Fraction 3). In between these two are intact grapes immersed in the juice and must of the crushed grapes (Fraction 2). Grapes inthis fraction undergo a modified autofermentation and are more likely to break down as the fermentation progresses.

The proportion of grapes in any one of these fractions depends on winemaking protocols and grape variety. The proportion of crushed grapes (Fraction 3) may be intentionally increased by foot stomping or destemming. Some varieties are more likely to break up during loading than others. For example, Merlot and Petit Verdot will have more crushing than thick skinned Cabernet Franc (Matthieu Finot, personal communication). The dimensions of the fermentation vessel also contribute to the amount of crushed vs. intact grapes. Tall thin tanks have a higher column of grapes weighing down the bottom clusters while shorter, broader vessels have less crushing.

From: Butler, Joel. Beaujolais Master Class

Autofermentation of grapes occurs in Fractions 1 and 2.

When grapes are picked, the cells inside the berries are still alive, and thus need a source of energy to maintain their cellular processes and organization. Under normal circumstances, they use oxygen from the atmosphere to break down sugar through aerobic respiration to produce CO2, water and energy. However, when atmospheric oxygen falls below 1%, the metabolism of the grape shifts to internal fermentation2. Carbon dioxide is heavier than oxygen, so when it is present, it will settle at the bottom of the tank and displace oxygen from the bottom up. In whole cluster fermentation, CO2 may be added through gas sparging, dry ice, or production by yeast fermentation of crushed berries1. Once present, CO2 is quickly absorbed into the grape berries, which absorb up to 60% of the berry volume of CO21.

The presence of CO2 in grape cells triggers several changes in berry metabolism. In the absence of oxygen, grape cells begin to convert sugar to ethanol through glycolysis followed by a final step that produces ethanol, a process much the same as yeast fermentation. Ripe berries already possess alcohol dehydrogenase, the enzyme used for the last step of this conversion2, however, unlike a yeast fermentation, in grapes this reaction only proceeds until 1.5-2% alcohol has been produced. At that point, the accumulated alcohol becomes toxic to the cell, causing a number of consequences that have effects on the resulting wine. By-products of fermentation including glycerol, acetic acid, and succinic acid begin to accumulate1. Cell membranes break down, releasing organic acids that cause a decrease in cellular pH, and further inhibition of fermentation1. Phenolic compounds are also released from cellular compartments; anthocyanins and eventually tannins leach from skins into the pulp. Seed tannins are rarely leached, as they require higher levels of alcohol to break down the seed coat1.

The CO2 rich, anaerobic environment of the grapes has many other effects on cellular metabolism beyond those caused by the accumulation of alcohol:

- Grape pectinases are induced by CO2, leading to the breakdown of pectin that holds cells together. The pulp loses its solid texture1.

- Up to 50% of the grape malic acid may be metabolized to other acids and ethanol without the accumulation of lactic acid. Tartaric and citric acids may also be affected, depending on the grape variety1,2.

- Modification of the metabolic pathway that usually leads to the production of amino acids instead leads to the production of volatile compounds such as ethyl cinnamate, benzaldehyde, ethyl decanoate, and many others. These compounds contribute to aromas of strawberry, raspberry, cherry and kirsch that distinguish whole cluster fermentations1,2.

- Lower oxygen presence limits the oxidation of fatty acids that can lead to production of C6 compounds hexyl acetate and hexanol, known for vegetal, tomato-leaf flavors and aromas1,2.

- Intracellular enzymes break down proteins, releasing amino acids that can later serve as nutrients for yeast and bacteria as well as and precursors to flavor and aromas1,2.

Grapes in Fractions 1 and 2 experience autofermentation to some degree, however, the more grapes are submerged in fermenting must (Fraction 2), the less character of autofermentation is found it the wine. This is because ethanol produced by fermenting must diffuses into the intact grape berries, increasing the alcohol concentration inside the grape. Initially, this triggers production of aromatic compounds1, and increases the extraction of phenolics1,4, but it also leads to much faster cell death4. Additionally, bathing berries in alcohol leads to faster breakdown of skins, meaning the berries stay intact for a shorter period of time. Though this process limits the effects of autofermentation, it does lead to some preservation of varietal characters, which can be lost during autofermentation4. Also, submersion of burst berries in the fermenting must further increases phenolic extraction. This means whole berry fermentations, or those with lower proportion of whole cluster inclusion, may have less strawberry/raspberry/cinnamon aromas but higher color, tannin, and varietal aromas.

The alcoholic fermentation (Fraction 3)

The activities of the fermentation in Fraction 3 are beneficial to the remaining fractions. CO2 production displaces oxygen, encouraging autofermentation in berries and limiting aerobic yeast such as Acetobacter and Klockera from producing acetic acid and ethyl acetate. A robust yeast fermentation also produces heat, which has several benefits (see below)1.

Though Fraction 3 undergoes a familiar yeast fermentation, there are several aspects to this fermentation that are different from a traditional fermentation. The initial volume of juice is usually very low, but additional juice, sugar, and nutrients are added over time as berries burst. This means the kinetics of the yeast population is governed less by a ‘boom and bust” than by steady buildup. Rather than building up, ethanol, the toxic by product of fermentation that eventually inhibits yeast, is partially removed by diffusion into intact grape berries. As a consequence, at the time of pressing, there is usually a healthy population of yeast on the order of 1x107cells/ml, capable of robust completion of fermentation post pressing1. This is not the case, however, if the fermentation is allowed to go through extended maceration, since the yeast may have run out of sugar.

Fraction 3 also differs markedly from traditional fermentations due to the presence of stems. Stems can make up 2-5% of the overall weight of the grape cluster and their presence has an impact on fermentation in both physical and chemical ways3. Physically, stems are found interspersed among skins and seeds in the cap, loosening compaction. This allows better mixing during cap management and less stratification of temperature in the fermentation. Generally, these fermentations are characterized by greater retention of volatiles that give varietal character, and gentler extraction of seed phenolics3. Chemically, stems add potassium, which can lead to high pH as potassium binds with tartaric acid to form insoluble bitartrate. Stems also contain methoxypyrazine (over 50% of the pyrazine in grape clusters are found in the stems5) that can lead to vegetal/herbal notes. Stems also contain phenolics of their own, which can be seen as a benefit or detriment depending on the wine. Paul Draper from Ridge Vineyards avoids using stems in his Cabernet Sauvignon and Zinfandel, as he feels he already has an abundance of tannin3. However, others, like Matthieu Finot of King Family Vineyards, use whole clusters to add to the tannin profile (personal communication), especially in varieties that lack them. These tannins, though challenging in young wines, soften over time to show silky texture and add spiciness to the wine, adding to its ageability3. This is probably why whole cluster fermentation is often applied to low tannin varieties like Pinot Noir and Syrah3.

Though the physical and chemical processes active in the three fractions are similar in any whole cluster fermentation, the outcomes depend on a number of decisions by the winemaker, including the proportion of the fractions, the duration of the initial fermentation, and the temperature. Whole cluster inclusion can be anywhere from a small proportion (5-10%) to 100%, and this proportion will have significant effects on the finished wine. In true carbonic maceration, for example, clusters remain whole with care taken to limit Fractions 2 and 3 as much as possible. These wines are pressed early and most of the fermentation is completed post-pressing. This approach maximizes the effects of autofermentiton with little to no impact of stems, seeds, or skins, producing fruity, early releasing wines with little aging potential. By contrast, many winemakers take the approach used for production of Cru Beaujolais, where 100% whole clusters are used, but a small proportion is crushed (by loading or foot stomping) to initiate alcoholic fermentation in the vat. The wine continues to be held in contact with skins, seeds, and stems as berries break down, allowing significant extraction of phenolics and better aging capacity.

The temperature of the fermentation this stage can also have a profound effect on the resulting wine. As with any fermentation, warmer temperatures speed all reactions, including those involved in cellular breakdown and formation of volatile compounds. Higher temperature also aids in the extraction of phenolic compounds, leading to more structured wines. In traditional fermentations, high temperature can lead to loss of volatile compounds due to high CO2 production and simple volatilization. However, in whole cluster fermentations, many of the volatile compounds are still contained in intact berries, not subject to these losses. Optimal temperatures for flavor development in carbonic maceration is thought to be 30-32°C (86-90°F) while in Beaujolais, the preferred temperature for fermentation is 18-22°C (64-72°F). Whole cluster fermentations that are too cool have only limited impacts of autofermentation1,2,6.

Pressing and the second fermentation

The decision of when to press a whole cluster fermentation depends on the goals for the wine. For true carbonic maceration, grapes are pressed when they have reached 2% internal alcohol and no longer show signs of additional autofermentation. This usually occurs after 5-8 days in a CO2 rich atmosphere at 32°C (90°F), but can take up to 15-20 days at lower temperatures (15°C, 60°F). In a Beaujolais-style fermentation, wine is pressed when Fraction 3 nears the end of its fermentation and CO2 evolution is slowing. In more traditional fermentations with whole cluster inclusion, extended maceration is also sometimes done.

There is also a marked difference between free run and press juice in these fermentations. The free run represents wine from Fraction 3, which is likely to be tannic, potentially bitter, and nearly finished with fermentation. In carbonic maceration, this is the least preferred portion. The press fraction will contain aromatic compounds including fruity esters from autofermentaiton and unreleased volatile varietal compounds, color and skin tannins. This will also include additional sugar that will likely be released when intact berries are pressed. In carbonic maceration or Beaujolais style whole cluster fermentations, a healthy yeast population has built up and will finish fermentation promptly. However, if the must in Fraction 3 has finished fermentation, the yeast population may have begun to die off and the must has likely cooled off, making it difficult to complete the fermentation. Additionally, if malic acid bacteria or Brettanomyces are present, release of sugar can lead to rapid accumulation of acetic acid. For this reason, some winemakers will add lysozyme or chitosan to the press juice to prevent spoilage (Matthieu Finot, personal communication) while others will keep the fractions separate at least until the completion of fermentation. Due to depletion of malic acid during autofermentation, malolactic fermentation usually proceeds quickly and is done early2.

References

(1) Jackson, R. S. Wine Science: Principles and Applications, 4 edition.; Academic Press: Amsterdam, 2014.

(2) Tesniere, C.; Flanzy, C. Carbonic Maceration Wines: Characteristics and Winemaking Process. Adv. Food Nutr. Res. 2011, 63, 1–15.

(3) Goode, J. Stemming the Tide. The World of Fine Wine 2012, No. 37, 90–97.

(4) Bisson, L. F. Geographic Origin and Diversity of Wine Strains of Saccharomyces. American Journal of Enology and Viticulture 2012, 63 (2), 165–176.

(5) Zoecklein, B. W. Herbaceous Character in Red Wines. Enology Notes, 2006.

(6) Bisson, L. F. Grape and Must Processing. In Intoduction to Wine Production Course; Davis, California, n.d.