Developing a protocol for partial carbonic maceration in Merlot (2020)

Kirsty Harmon

Blenheim Vineyards

Summary

The purpose of this study was to develop a protocol for the partial carbonic maceration of Merlot in a small winery that does not have specialized equipment for this technique. To enhance the carbonic character of the wine, unchilled fruit was loaded as whole clusters into a metal tank and sealed, with continuous ingress of small amounts of CO2. The tank was warmed by placement outside for 7 days, then fruit was destemmed and fermented as a red wine. A TBin fermentation of grapes from the same vineyard served as a control. The resulting wines had very similar chemistry with little difference in color or acetic acid, a common spoilage character of whole cluster fermentations. The wine that underwent partial carbonic maceration had higher levels of ethyl acetate than the control, but within the range that lends complexity rather than spoilage character. The sensory characteristics of the wine were significantly different in a triangle test. The treatment wine had significantly higher descriptive scores for fruit intensity and body.

Introduction

The purpose of this study was to build upon experiments completed in 2016 and 2017 to develop a protocol for the partial carbonic maceration of Merlot in a small winery that does not have specialized equipment for this technique. The winemaking goal for this wine is to be used as a blending tool to fill out the mid palate and lend complexity to Blenheim’s varietal Merlot product.

In 2016, Merlot grapes were sealed in a tank with a small amount of fermenting juice at the bottom to release CO2 into the atmosphere. The tank was flushed with CO2 twice daily. At the end of 5 days of carbonic maceration in this matter, free run juice was separated and grapes were pressed then allowed to complete fermentation in a tank. This approach produced an interesting wine, but it had considerably lower phenolic and color measures than a control wine and was not suitable to be used as a part of a blended red wine.

In 2017, in an effort to address the lack of color in the carbonic maceration wine, the protocol was refined to include a period of traditional maceration after carbonic treatment. However, the winemaker wanted to avoid stemminess in the wine. The grapes were once again sealed in a tank with fermenting juice for 7 days, after which they were destemmed into TBins and fermented to dryness on skins and seeds. The resulting wine had better color intensity than in 2016 but this measure was still lower than control, while phenolic measurements were roughly half what was found in a traditional fermentation of the same grapes. Sensory analysis revealed the wines were significantly different, with higher esters in the wine that underwent carbonic maceration treatment and higher astringency in the traditionally fermented wine.

In the present study, several additional refinements were made to increase the carbonic character of the wine. Autofermentation, the internal metabolism of sugars by intact grapes, only begins when atmospheric oxygen falls below 1%1 and the grape berries can themselves absorb up to 60% of the berry volume worth of CO22, therefore a strong and consistent source of CO2 is needed to trigger the changes in berry metabolism most associated with the flavor profile of carbonic maceration. For this reason, CO2 was continually gassed into the sealed tank to displace oxygen and provide adequate CO2. Consistent CO2 dosing also displaces oxygen and helps prevent accumulation of acetic acid and ethyl acetate, common spoilage characters for whole cluster and carbonic wines.

The temperature of the fermentation can also have a profound effect on the resulting wine. As with any fermentation, warmer temperatures speed all reactions, including those involved in cellular breakdown and formation of volatile compounds. In traditional fermentations, high temperature can lead to the loss of volatile compounds due to high CO2 production and simple volatilization. However, in whole cluster and carbonic maceration fermentations, many of the volatile compounds are still contained in intact berries, not subject to these losses. Optimal temperatures for flavor development in carbonic maceration is thought to be 30-32°C (86-90°F) while in Beaujolais, the preferred temperature for fermentation is 18-22°C (64-72°F). Whole cluster fermentations that are too cool have only limited impacts of autofermentation1–3.

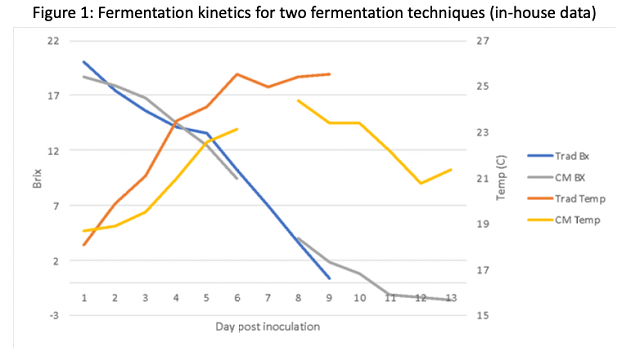

Without the added heat from fermenting yeast, it is difficult to achieve these temperatures without active warming. Blenheim does not have the capacity to heat tanks, however, cooling can be withheld to allow for warmer fruit processing. In this experiment, fruit was loaded into the carbonic maceration tank without chilling the fruit, and the carbonic maceration tank was kept outside in the shade (under cover) for the duration of the treatment to increase the temperature during carbonic maceration. In 2020, cooler ambient temperatures probably limited the effectiveness of this technique, however, in more normal years, ambient daytime temperatures during harvest can be up to 85-90°F.

Methods

Approximately 1.5 tons of Merlot from the same vineyard were used for the experiment. Fruit was processed into either a 1000L stackable stainless steel tank for carbonic maceration or into a TBin for traditional fermentation.

For Carbonic Maceration, un-chilled fruit was processed into a 1000L stackable stainless steel tank that was first flushed and filled with carbon dioxide. Whole cluster Merlot grapes (0.61 tons) were added to the tank, then the tank was completely sealed. The tank fittings included a gas nozzle on the bottom valve and a pressure release valve on the top to release excess carbon dioxide without allowing oxygen ingress. CO2 was hooked to the gas nozzle to supply a steady stream of gas to this tank at a slow rate throughout the duration of carbonic maceration. The tank remained sealed for 7 days and was placed outside on a covered crush pad to warm. There was no free run juice to sample during this time. At the completion of 7 days, grapes were destemmed and loaded into a Tbin, then inoculated with 5 liters of fermenting must from the traditional fermentation. Fermenting must was punched down twice daily until the completion of fermentation. Brix and temperature were monitored daily during fermentation and grapes were pressed at the completion of fermentation. All other processes were the same as those done in the traditional fermentation.

As a control, a TBin fermentation from the same lot of grapes was treated with the standard protocol of the winery. Grapes were sorted, destemmed and loaded into TBins with the addition of 50 mg/L SO2 (as a KMBS addition). Tbins were inoculated with 20g/hL of EC1118 yeast the day after processing. There were no additions of sugar, nutrients, or acid. Fermentations were monitored daily for Brix and temperature with twice daily punchdowns throughout the fermentation until Brix measured lower than -1.5. Once negative Brix had been reached, fermentations were pressed with free run and press fractions combined. Wine was inoculated with Scott Labs MBR process (0.01 g/L), allowed to settle for 3-4 days, then transferred to barrel for malolactic fermentation in comparable barrels. For both lots, malic acid depletion was monitored every 4 days. SO2 (75 ppm) was added two weeks after malic acid was determined to be less than 0.1 g/L by in-house enzymatic analysis.

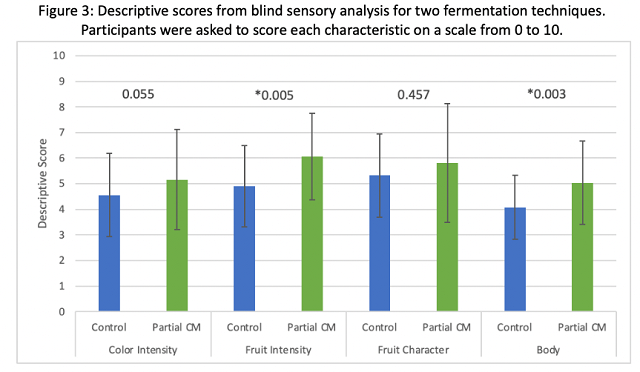

Sensory analysis was completed by a panel of 35 wine producers. Due to restrictions put in place during COVID-19, sensory analysis was completed using shipped samples. Each wine producer received three wines in identical bottles, filled on the same day, each coded with random numbers. Two of the bottles contained the same wine while the third bottle contained the different wine. Participants were asked to identify which wine was different (a triangle test). There were four tasting groups with the unique wine in the triangle test balanced among the groups. Participants were then asked to score each wine on a scale of 0 to 10 for color intensity (low to high), fruit intensity (not fruity to very fruity), fruit character (from tuti-fruiti to varietal Merlot), and body (from thin to full). Additional description for fruit character included information that “Tuti-fruiti can be described as strawberry, raspberry, and tropical banana, like Juicy Fruit gum. Classic Merlot characters include cherry, plum, tobacco”. Participants were also given open ended questions to describe the wines. Results for the triangle test were analyzed using a one-tailed Z test. Descriptive scores were analyzed using repeated measures ANOVA. Scores for descriptive characteristics were analyzed only from participants who were able to distinguish the two wines (those who answered correctly in the triangle test).

Results

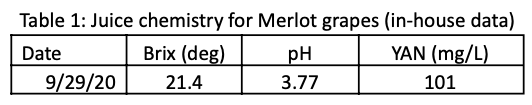

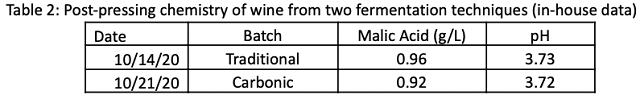

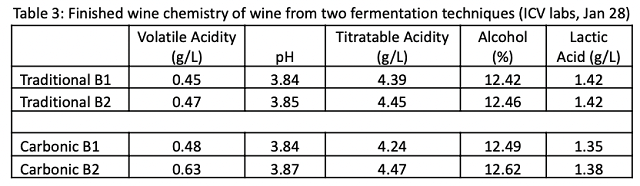

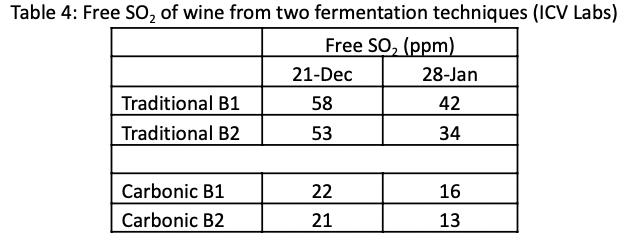

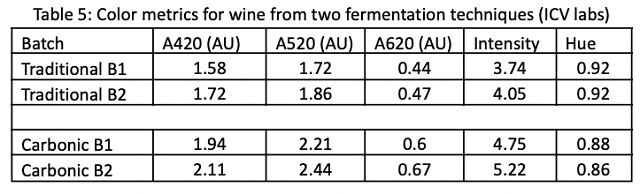

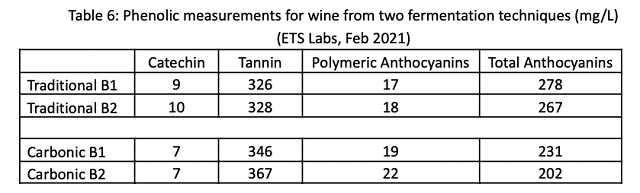

All of the fruit for this experiment came from the same lot of grapes (Table 1). Post-inoculation fermentation progressed smoothly for both lots, with the traditional lot fermenting slightly warmer than the carbonic lot (Figure 1). Both lots reached the temperature range recommended for Beaujolais style fermentation. At the completion of fermentation, both lots had comparable malic acid and pH levels (Table 2). The finished wine chemistry was also very similar between the lots (Table 3). The wine that experienced partial carbonic maceration bound more SO2 at the initial stage, and the wine aged with less free SO2 as a result (Table 4). Differences in color intensity between the wines is likely affected by this difference in SO2 (Table 5). The wine that experienced carbonic maceration had higher measures of tannin but lower measures of anthocyanins than the traditionally fermented wine (Table 6).

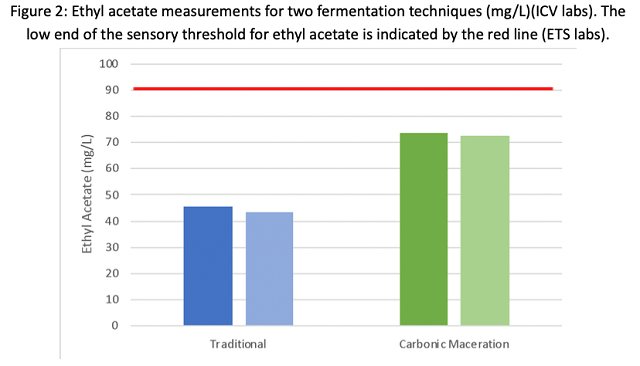

One common byproduct of carbonic maceration is the production of ethyl acetate, presumably by spoilage microbes such as Hanseniaspora, Pichia, and Acetobacter present on the skins of grapes2. Aerobic microbes usually persist until oxygen has been flushed from the fermentation, and their presence can result in high levels of acetic acid as well as ethyl acetate. While acetic acid smells like vinegar, ethyl acetate smells like nail polish remover, glue or varnish, but only above its sensory threshold, which ranges from 90-150 mg/L. Below this threshold, ethyl acetate can lend richness and sweetness to wines, and improve complexity4. In this experiment, the wine that underwent carbonic maceration had higher measured levels of ethyl acetate than the wine that was fermented with traditional methods. However, ethyl acetate levels for both treatments was below the sensory threshold (Figure 2).

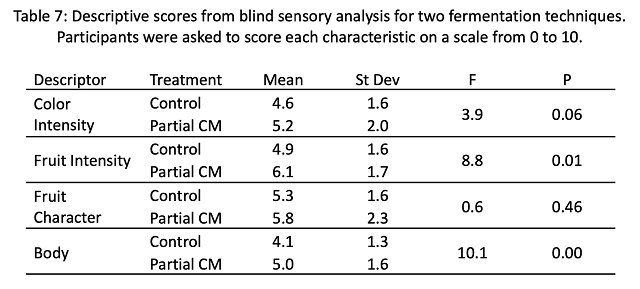

In a triangle test of control vs. partial carbonic wines, 24 out of 35 respondents were able to distinguish which wine was different, indicating the wines were significantly different (Z=4.60, p<0.00003). Mean scores for the wine that underwent carbonic maceration were significantly higher for fruit intensity and body, however there were no significant differences in scores for fruit character and color intensity (Figure 3, Table 7). When asked to list descriptive terms that helped distinguish the wines from one another, participants described the control wine as “earthy” and as having “less color” more than the wine treated with partial carbonic maceration. The treated wine was described as “fruitier”, with “more volume, structure, fruit on palate” and “slightly more color”.

Subjecting Merlot grapes to conditions that led to carbonic maceration (warm loading, continuous CO2 in a sealed tank) followed by destemming and fermentation on skins and seeds achieved the goal of increasing body and complexity while avoiding spoilage characteristics.

References

(1) Tesniere, C.; Flanzy, C. Carbonic Maceration Wines: Characteristics and Winemaking Process. Adv. Food Nutr. Res. 2011, 63, 1–15.

(2) Jackson, R. S. Wine Science: Principles and Applications, 4 edition.; Academic Press: Amsterdam, 2014.

(3) Bisson, L. F. Grape and Must Processing. In Introduction to Wine Production Course; Davis, California, n.d.

(4) ETS. Ethyl Acetate. ETS.