Whole Cluster Fermentation in Petit Verdot

Matthieu Finot

King Family Vineyards

Summary

Whole cluster fermentation has the potential to provide increased complexity, fruitiness and strong tannins to the wine. However, whole cluster fermentations can also include bitter phenolics and spoilage from oxidative yeast. The purpose of this study was to test a procedure for whole cluster fermentation that limited spoilage while developing a rustic, powerful style of Petit Verdot. Key elements in the protocol include using warm fruit and foot stomping to produce a rapid start of fermentation in the liquid fraction that protects the whole clusters from spoilage and triggers autofermentation. Finished wines from 100% whole cluster, 50% whole cluster/50% destemmed and 100% destemmed treatments showed very similar basic chemistry with no indication of spoilage in any of the treatments. Color decreased with increasing proportion of whole cluster. Sensory impacts included additional fruitiness and tannic grip with increasing proportion of whole clusters. This protocol successfully produced clean wines with different styles.

Introduction

Utilizing whole clusters rather than destemmed or crushed fruit has several consequences for fermentation leading to fruitier wines often with less color and potentially sharper tannins. Several chemical processes are at play:

- Anaerobic metabolism inside the grape can lead to loss of malic acid, increase in some fruity aromas and flavors and loss of some varietal character1–3.

- Some fruity aromas and flavors are retained inside berries that would otherwise be lost to volatilization during fermentation3.

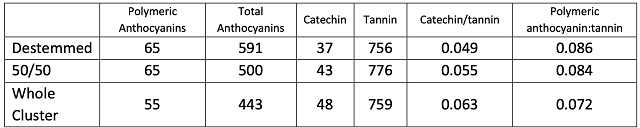

- Inclusion of stems can lead to some loss of color, increases in potassium (with drop in acid), and potential increases in phenolics such as catechin and tannin4.

- Whole cluster fermentations are often cooler than traditional fermentations. It takes longer for a cap to form. Cap management after berries begin to break down is more successful at breaking up the cap fully due to less compaction of berries and stems1,4.

- There is often less extraction of phenolics from skins and seeds as there is less contact time for alcohol-based solubilization1.

In addition, whole cluster fermentations include potential for pockets of oxygen persisting for some time, allowing for spoilage by aerobic yeast and bacteria. Some whole cluster fermentations are characterized by acetic acid and ethyl acetate, leading to aromas of vinegar and nail polish remover1. However, these fermentations can also lead to increased complexity and a more rustic style of wine. The purpose of this experiment was to implement a series of strategies to allow for whole cluster fermentation in Petit Verdot that avoids spoilage and leads to a rustic, powerful wine. Specifics of each step with rationale are outlined in the following protocol.

Methods

There were three treatments:

- 100% destemmed fruit

- 50% destemmed, 50% whole cluster

- 100% whole cluster

For all treatments, grapes were loaded into bins immediately after harvesting. Processing of un-chilled grapes allowed for a fast start to fermentation. In whole cluster fermentations, spoilage by non-Saccharomycesyeast (Klockera) and bacteria (Acetobacter) resident on the grapes can lead to high levels of acetic acid and ethyl acetate. By starting fermentation quickly, CO2 is produced that displaces oxygen, a needed substrate for spoilage.

Whole cluster treatment

Grapes were loaded into TBins from harvest bins as whole clusters. After 1/3 of the whole clusters were loaded into the TBin, grapes were stomped to produce enough juice for the initial fermentation to begin. A well-mixed vineyard starter culture of yeast was added to inoculate the fermentation. Appendix A contains a protocol for preparation of the vineyard starter culture. Stab Micro M (14 g/hL) was also added to further prevent microbial spoilage.

Standard protocol (for destemmed and 50/50 lots)

Grapes were destemmed to TBins the same day as harvest with the addition of 20 ppm SO2. One bin received 100% destemmed fruit while the other received 50% (by weight) destemmed fruit, 50% whole clusters added to the bin at the same time. Bins were inoculated with the same well-mixed vineyard starter culture as the whole cluster bin.

For all treatments, cap management occurred twice per day. The destemmed and 50/50 lots were punched down while the whole cluster lot was foot stomped until a cap formed, at which time it was punched down. All bins were pressed the same day (10/23) for a total of 24 days of overall maceration. Wine was allowed to settle for 1-2 days prior to racking and transfer to identical barrels. Malolactic conversion occurred naturally in barrel. At the completion of malolactic fermentation, 3 g/hL Stab Micro (Enartis), 2.5 g/L tartaric acid and 66ppm SO2 were added to each barrel.

Results

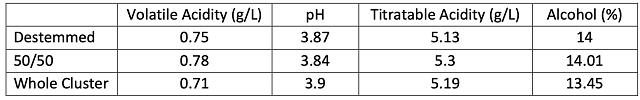

Grapes were harvested at 22.1° Brix with a pH = 3.48 and TA = 5.7 g/L. There were no large differences in general wine chemistry between lots (Table 1). Studies in other varieties have shown pH increases with increasing proportion of stems, presumably due to increased potassium leaching from stems in whole cluster fermentations. That trend is not evident here. Perhaps this is due to the high potassium levels found in Petit Verdot skins, present in all three treatments.

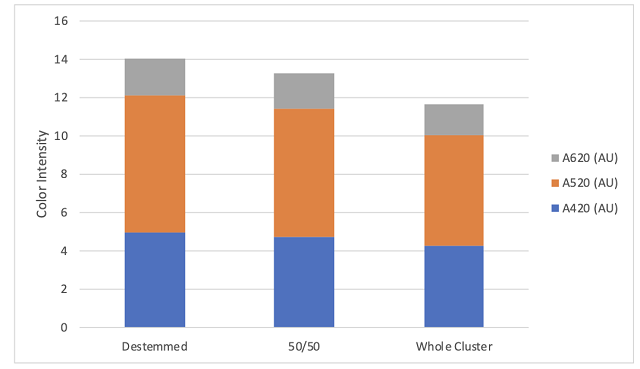

The volatile acidity is notably similar for all three treatments. Accumulation of volatile acidity is a primary concern in whole cluster fermentations and was a driver of this experiment. From these data, this protocol appears to be effective in combatting early spoilage due to oxidative yeasts and bacteria. Color (Figure 1) and anthocyanin content (Table 2) decreased with increasing proportion of whole clusters.

Full sensory analysis was not possible due to social distancing guidelines during the COVID-19 outbreak. The winemaker and research coordinator report increased fruitiness and tannic grip in the 100% whole cluster fermentation while the control was characteristic of a well made Virginia Petit Verdot. The 50% whole cluster treatment showed intermediate impacts, as expected.

Table 1: General wine chemistry for three treatments of Petit Verdot (ICV labs)

Figure 1: Color intensity for three treatments of Petit Verdot (ICV Labs)

Table 2: Rapid phenolic analysis for three treatments of Petit Verdot (mg/L) (ETS Labs)

References

(1) Jackowetz, N.; Li, E.; de Orduña, R. M. Sulphur Dioxide Content of Wines: The Role of Winemaking and Carbonyl Compounds. Appellation Cornell 2011, 3, 1–7.

(2) Tesniere, C.; Flanzy, C. Carbonic Maceration Wines: Characteristics and Winemaking Process. Adv. Food Nutr. Res. 2011, 63, 1–15. https://doi.org/10.1016/B978-0-12-384927-4.00001-4.

(3) Bisson, L. F. Grape and Must Processing. In Introduction to Wine Production Course; Davis, California, n.d.

(4) Goode, Jamie: Stemming the Tide, World Of Fine Wine, Issue 37, 90-97. 2012 http://www.worldoffinewine.com/news/stemming-the-tide-4869650 (accessed Apr 30, 2020).

Appendix A: Protocol for preparing a vineyard starter culture

To prepare a starter for the ambient fermentation, 4-5 days prior to harvest, clean clusters were picked and crushed into a cleaned and sanitized 6 gallon bucket with a removable lid. A single SO2 addition of 30 ppm was made. The container of crushed fruit was kept in the vineyard to limit exposure to commercial yeast in the winery and allow the native yeast fermentation to begin. Temperature of the starter was kept near 26°C (by shading or sun exposure). The starter was monitored for Brix depletion and temperature daily (or twice per day if it is moving briskly). The starter was oxygenated after 2 or 3 days. When the starter was around 1.045 - 1.030 (8 - 12° Brix), pomace in the bucket was strained and the fermenting juice was used for inoculation. The starter was tasted before inoculation to be sure that VA and ethyl acetate are not too high.