The Stylistic Impact of Different Cap Management Procedures in Cabernet Franc (2018)

Kirsty Harmon

Blenheim Vineyards

Summary

Decisions as to the type and duration of cap management during red wine fermentation can have a significant impact on aroma, flavor and chemistry of the resulting wine. Punching down and pumping over bathe the cap in liquid, help minimize microbial spoilage, introduce oxygen to the fermentation, dissipate temperature buildup and reduce saturation of extracted phenolics. The purpose of this study was to compare the effects of gentle punch downs with short pump overs in Cabernet Franc. The winemaking goal for this wine was to produce an early bottling fruit forward style. Punch downs resulted in a slightly warmer cap temperature that was not fully integrated by cap management. Slightly higher levels of phenolics were seen with punch downs vs. pump overs. In a triangle test, 17 out of 28 respondents were able to distinguish these wines, indicating the wines were significantly different (Z=2.873, p=0.002). However, there were no significant differences in scores for fruit intensity, astringency or herbal/green character.

Introduction

Cap management of red wine fermentations is a time consuming but crucial. As CO2 is released during fermentation of red grapes, the solid mass of skins rises so that 1/3 of the skins may be out of contact with liquid. Extraction of phenolics, aromatics and polysaccharides from pomace requires contact with liquid, so immersing these solids is an important element in flavor development. Extraction is also governed by diffusion, and as more compounds are extracted from the solids in the cap, they can experience local saturation (Lerno et al 2017). Cap management helps to homogenize these elements throughout the fermentation vessel, encouraging further extraction (Ribereau-Gayon et al 2006). However, when used excessively, over-extraction of phenolics can lead to dry tannins or bitterness (Razungles 2010). Decisions as to the type, duration, and frequency of cap management all contribute to the extraction of these compounds into the final wine.

Cap management also plays a role in managing the microbes in the fermentation. During cap management, aerobic microbes such as Acetobacter are submerged into an environment lacking in oxygen, thus limiting production of acetic acid and ethyl acetate. Bathing the cap in fermenting liquid exposes lurking microbes to alcohol, many of which are sensitive or intolerant to alcohol levels higher than 4%. Oxygen introduction into the fermenting liquid also helps increase yeast cell production of cell membrane components that will help them tolerate rising alcohol levels later in fermentation. Oxygen introduced during cap management is also important in tannin evolution and stabilization of anthocyanins (Ribereau-Gayon et al 2006).

Another important element of cap management is the effect on temperature. Heat accelerates the enzymatic break down of cell walls, loosens cell membranes and makes them more permeable, and increases diffusion rates of chemicals in liquid, all of which contribute to greater extraction of compounds from fermenting grapes. Most notably in red wine fermentations, heat during fermentation increases extraction of phenolics but also increases the rate at which anthocyanins are lost, leading to more tannin and less color (Razungles 2010, Ribereau-Gayon et al 2006). Heat can also lead to the loss of volatile aromas, and stress yeast if it builds up too much (Ribereau-Gayon et al 2006).

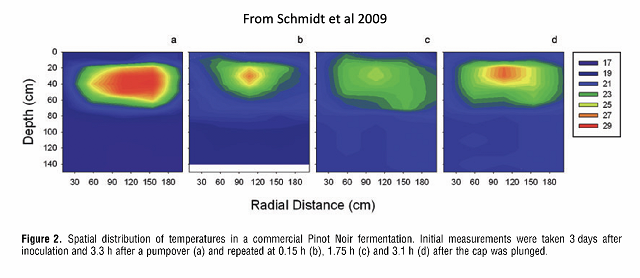

In a study looking at the formation of temperature gradients in red wine fermentations, Schmid et al (2009) measured the temperature in the cap at several locations during an active fermentation as well as at several depths of the fermentation before, during, and after cap management. In a 6-ton fermentation of Pinot Noir, there was up to 12°C difference in temperature between the cap and the liquid and a 6-8°C difference between the center and sides of the cap. The gradient was not always fully dissipated during routine cap management (Schmidt et al 2009). The figure shown below (from Schmid et al 2009) indicates heat at various depths in the tank over time. Panel (a) shows heat built up 3 hours after a 10 minute pump over, (b) shows heat immediately after punch down, and (d) shows the heat built up after 3 hours. Here, the heat in the cap 3 hours after pump over (a) is higher than 3 hours after punch down (d), indicating the punch down did a better job dissipating heat. However, panel (b) shows that this was incomplete homogenization. It is important to note that a temperature gradient was also found in three other fermentations studied, but to a lesser extent. The authors hypothesize the magnitude of the temperature gradient is affected by grape variety and processing, however do not elaborate on those differences.

In addition to managing heat, cap management helps to homogenize phenolics and presumably other flavor and aroma compounds extracted from the cap. In a study of chemical gradients during fermentation, Lerno et al (2017) found that gradients of anthocyanins, skin phenolics and seed phenolics all develop during red wine fermentations. Pumping over of one tank volume each day homogenized these gradients. When pumping over was not done, anthocyanins reached a saturation point after 24 hours on at least one day of the three monitored (days 2-4 of fermentation). In addition, extraction kinetics were different for different types of phenolics, with anthocyanins reaching maximum extraction after 24-72 hours of fermentation, gallic acid (a skin phenolic) continually increasing throughout the 10 days of monitoring, and catechin (a seed phenolic) beginning its extraction later in the fermentation. Cap management, therefore, is also phenolic management.

Cap management is most often done as a pump over or punch down. Pumping over involves the pumping of fermenting liquid from the bottom of the tank over the cap, sometimes with intentional aeration. The duration of pump over varies considerably from cellar to cellar, and often reflects the stage of fermentation, with aeration in the beginning of the fermentation and longer pumping over in the active stages of fermentation (Razungus et al 2010). It is thought that to obtain full extraction, pumping over the full volume of the tank each day (usually in two events) is sufficient in the first few days of fermentation and half the tank volume is sufficient in the second half of fermentation (Razungus et al 2010, Ribereau-Gayon et al 2006). At any stage, pump over should thoroughly wet the cap, including sides and center of the tank.

Pumping over may be done in an aerative fashion to supply oxygen to fermenting yeast and help degas CO2that can inhibit yeast action (Ribereau-Gayon et al 2006). This may be simply by “fireshosing” the liquid or by sending liquid through a sump cart prior to pumping over the cap. It is most important to add oxygen at the beginning of fermentation when yeast can make sterols that act as survival factors to stabilize their cell membranes once the alcohol levels rise. Ribereau-Gayon et al (2006) recommend aeration on the second and third day of fermentation for the best effect. Once fermentation slows, it is good to limit oxygenation during cap management to avoid oxidation of the wine. Punching down includes the displacement of solids into the fermenting liquid by a punching tool. This is usually done until the cap is physically broken up and the floating solids are well wet by fermentation liquid. Oxygen is introduced as liquid from the surface is forced down into the tank.

Due to physical breakup of the cap, punching down is thought to increase skin extraction, promote extraction of seed tannin, and increase the tannic structure of the wine. It is often recommended for lighter varieties like Pinot Noir but not for more tannic varieties like Cabernet Sauvignon or Merlot (Ribereau-Gayon et al 2006, Razungus 2010). Pumping over is not believed to affect tissue integrity, and is thought to be more gentle, limiting vegetal or bitter extraction (Ribereau-Gayon et al 2006). In a review of the effect of winemaking techniques on phenolic extraction in red wines, Sacchi et al (2005) found the comparison of effects of punch downs vs. pump overs varied by variety. Early work shows that more color and tannin are present in wines managed with pump overs. More recent studies show that quercetin, a skin tannin, increased in pump over vs. mechanical or manual punch down while differential extraction of other phenolic components is variety dependent. In Pinot Noir especially, mechanical punch down or pump over greatly increased extraction (100-200%) over manual punch down with mechanical punch down extracting more, but this effect was not seen as strongly in Dornfelder. In another study, anthocyanins, catechin (a seed phenolic) and total phenolics were greater in wines managed with pump overs vs. punch downs for Negramano and Primitivo but for Sangiovese there was little difference, and in Pinotage, there were lower levels of phenolics with pump overs vs. punch downs. Sacchi et al (2005) point out that the effect of pump over is dependent on timing during fermentation and is influenced by both temperature and whether skins circulate through the pump.

The purpose of this study is to compare the effects of gentle punch downs with short pump overs on Cabernet Franc. The winemaking goal for this wine was to produce an early bottling fruit forward style. The goal of the study was to understand the influence of cap management strategies on the style of the final wine including basic chemistry, phenolic composition and sensory differences.

Procedure

Cabernet Franc grapes were picked on 9/13/18 from a single block and chilled overnight. Grapes were then sorted, destemmed and loaded into identical 3000 L variable capacity stainless steel tanks with 50 mg/L SO2. Each tank received 5200 pounds (2.6 tons) of grapes. Tanks were inoculated with 15g/hL of EC1118 yeast the following day, after the tank temperature reached 10°C (50°F). There was no acid addition. A total of 0.7 kg/ton of sugar was added in two separate additions on 9/18/18 and 9/20/18. No nutrient additions were needed. Fermentations were monitored for Brix and temperature each day, with maximum tank temperature set to 85°F.

Gentle cap management occurred twice per day with the goal of wetting the cap only. Both punch downs and pump overs were timed for a duration of two minutes. During a pump over, wine was “firehosed” over the top of the cap for the first minute to introduce oxygen. The temperature of the cap was recorded prior to and after cap management.

Fermentation was considered complete on 9/28/18 when the Brix reading was negative. Both tanks were pressed on the same day with free run and press combined. The wine was settled for four days and then racked to identical barrels and inoculated with 1 g/225L barrel Scott Labs MBR process. Malic acid depletion was confirmed by in-house analysis on 10/22/18. SO2 and 2 g/L tartaric acid were added on 11/13/18. Wine was not racked after the completion of malolactic fermentation.

Sensory analysis was completed by a panel of 28 wine producers. Wines were presented blind in randomly numbered glasses. Panelists were presented with three wines, two of one type and one of another, and asked to identify which wine was different (a triangle test). They were then asked to score each wine on a scale of 0 to 10 for fruit intensity, astringency, and green/herbal character. Panelists were also given open ended questions to describe the wines.

Results

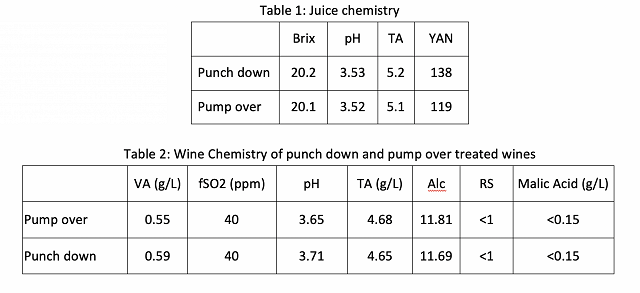

The initial juice chemistry of each tank was very similar (Table 1) as was chemistry of the finished wines (Table 2).

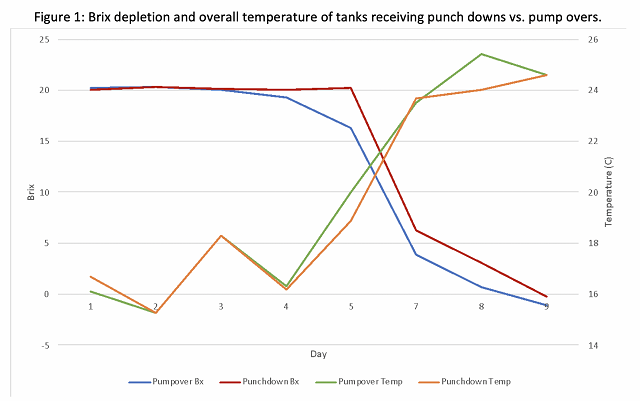

Overall fermentation kinetics and tank temperature as measured from the tasting valve were largely the same. The fermentation in the tank receiving punch downs was slightly slower than the fermentation in the tank receiving pump overs (Figure 1). The tank receiving pump overs reached 3.9 Bx on 9/21/18 (day 7) while the tank receiving punch downs was at 6.3 Bx on the same day, and 3.1 Bx on day 8.

Temperature

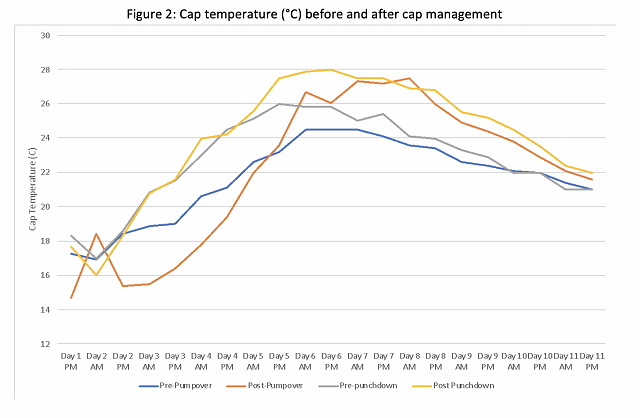

In addition to temperature of the liquid phase, cap temperature was also measured before and after cap management each day (Figure 2). Cap temperature overall increased days 2-7, a time period that also corresponded to a period of rapid fermentation (Figure 1). Overall, the tank receiving pump overs had a lower temperature cap than the tank receiving punch downs (up to 2°C difference), indicating the pump over was a more thorough mixing of cool liquid phase with the cap. Due to the depth of the cap during this time, it is likely the punch down was not fully mixing liquid from the cap with liquid from further into the tank.

During the initial phases of fermentation, days 1-4, cap management resulted in a decrease in cap temperature. Cap temperature at this time was higher than the fermenting liquid beneath, thus mixing resulted in cooling of the cap. In the final stages of the fermentation, cap management resulted in an increase in cap temperature. Here, the cap was radiating heat faster than it was being produced by the fermentation. Warm liquid from the medium likely improved extraction at this time.

Conclusions

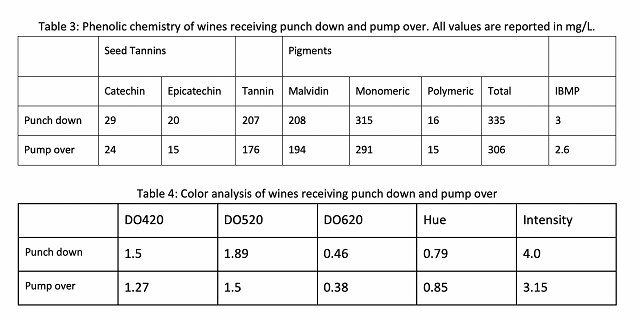

Punch downs resulted in a slightly warmer cap temperature that was not fully integrated by cap management. This is likely due to differences in the depth of mixing, as pump overs are drawing wine from the bottom of the tank, which according to Schmidt et al (2009) can be considerably cooler while punch downs are limited by the depth of the punch down tool. As the fermentation progresses, the liquid in the rest of the tank is heated by active fermentation, and has higher thermal inertia than the cap, providing heating to the cap longer than punch downs. Slightly higher levels of phenolics were seen with punch downs vs. pump overs. This could be due to physical shearing of grapes during punch down or higher levels of heat increasing the extraction rate early in the fermentation. Tasters were able to distinguish between the wines during blind tasting, however there were no significant differences in scores for specific descriptors. Sensory analysis was done without standards and training, making it more difficult to quantify differences in specific descriptors. Tasters were given open ended questions to list what made the wines different but the responses showed not clear trends, making it difficult to know what was different between the wines.

This study included very minimal cap management, with short duration of punch down and pump over. If pump overs were carried out for longer, different effects may be seen.

References

Lerno, L., M. Reichwage, S. Panprivech, R. Ponangi, L. Hearne, A. Oberholster, and D. E. Block. (2017) Chemical Gradients in Pilot-Scale Cabernet Sauvignon Fermentations and Their Effect on Phenolic Extraction. American Journal of Enology and Viticulture 68, no. 4 pp 401–11. https://doi.org/10.5344/ajev.2017.16104.

Razungles, A. (2010) Chapter 20: Extraction technologies and wine quality. In A.G. Reynolds (Ed.) Managing Wine Quality Volume 2: Oenology and Wine Quality (pp 589-625). Cambridge, UK: Woodhead Publishing.

Ribereau-Gayon,P., D. Dubourdieu, B. Done`che and A. Lonvaud (2006) Handbook of Enology Volume 1 The Microbiology of Wine and Vinifications 2nd Edition, Chapyer 12. West Sussex, England: John Wiley & Sons, Ltd

Sacchi, K.L., L.F. Bisson, and D.O. Adams. (2005) A Review of the Effect of Winemaking Techniques on Phenolic Extraction in Red Wines. American Journal of Enology and Viticulture 56, no. 3 pp 401–11.

Schmid, F, J. Schadt, V. Jiranek, and D.E. Block. (2009) Formation of temperature gradients in large and small-scale red wine fermentations during cap management. Australian Journal of Grape and Wine Research, 15 pp 249-255.