The Effect of Different Cap Management Techniques on Merlot Wine (2016)

Corry Craighill

Sunset Hills Vineyard

Summary

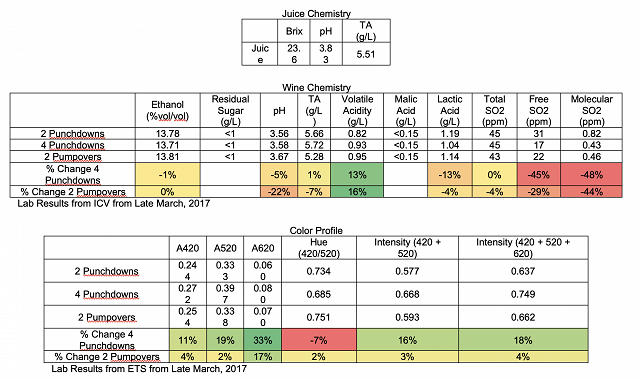

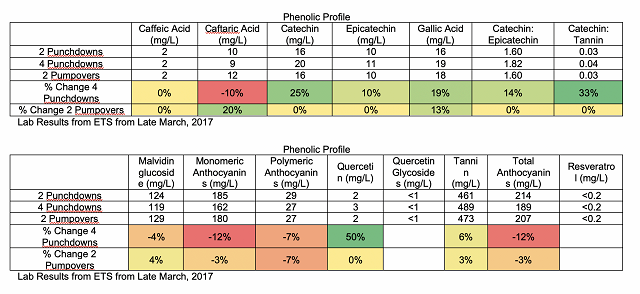

This study examines the effect of different cap management techniques on the chemical and sensory qualities of Merlot wine. Merlot grapes were harvested on the same day and split into 3 separate 1-ton T bins with three different treatments: 2 punchdowns per day, 4 punchdowns per day, and 2 pumpovers per day. The timing between 2 punchdowns and pumpovers were approximately 5-8 hours apart, and the timing between 4 punchdowns was approximately 1-2 hours apart. Increasing punchdowns and pumpovers increased the pH (5% and 22% lower proton concentration, respectively) and pumpovers slightly decreased TA. The treatments also increased the volatile acidity and increased the sulfur dioxide binding capacity of the wine. Increasing the number of punchdowns had the greatest impact on color, catechin, and tannin accumulation, although pumpovers slightly increased this as well. Anthocyanins were decreased by the treatments, especially with the 4 punchdown treatment. Overall, these wines were not perceived to be very different from each other. The 2 Punchdown wine seemed to be slightly more preferred than the rest of the treatments, but this was a weak preference. Descriptive analysis from both tastings suggest that the 2 Punchdown wine may have been slightly lower in Astringency, Bitterness, Body, and Herbaceous/Green character. However, if so then this was a very weak trend.

Introduction

Punchdowns and pumpovers are performed to increase the amount of time juice is in contact with the skins, and to help re-distribute heat (Sacchi et al. 2005). Contact of the juice with grape skins affects extraction of many grape compounds into the juice, but the extraction kinetics are complex and vary depending on the kind of compound and its origin. It is generally recommended that a thin cap with good cap management is important to avoid excessive extraction of bitterness (Zoecklein 2002a), likely due to better temperature management. Punchdowns are often recommended, as it is thought that punchdowns on mature fruit will produce wines with more fine-grained tannins. However, some varieties such as Merlot will often have lighter bodies if vinified with punchdowns, and alternative practices including extended maceration and the addition of exogenous tannin should be considered in these cases (Zoecklein 2002b).

Total volatile compounds tend to increase with increasing levels of skin contact (Ramey et al. 1986; Baumes et al. 1989; Moyano et al. 1994; Cabaroglu et al. 1997; Fischer et al. 2000; Selli et al. 2003; Mansfield et al. 2011). However, skins also seem to adsorb volatile compounds that develop more during fermentation, such as fatty acid precursors and hexanol-derived aroma compounds (Ferreira et al. 1995; Callejón et al 2012).

Additionally, high cap temperature could potentially result in higher astringency and bitterness (Schmid et al. 2009). However, this may not be offset by the increased mixing that must result from pumping over or punching down in order to keep the cap cool. Mechanical action on the cap is important, as this action can increase the amount of potassium extraction, which can result in more tartaric acid crystallization. This can also result in more anthocyanin precipitation (Bosso et al. 2011). Wines made from submerged cap vinification often have higher levels of anthocyanins, tannin, stronger color, and lower hue. This can occur despite floating cap pomace often exhibiting more extraction. Thus, floating cap wines tend to exhibit more precipitation of these compounds than submerged cap wines (Bosso et al. 2011).

Punchdowns and pumpovers also serve to degas the fermentation. Total pressure, as well as partial pressure of oxygen and carbon dioxide, are important factors in fermentation. Although low streams of carbon dioxide may stimulate fermentation, high carbon dioxide pressure lowers yeast growth and fermentative capacity (Amerine 1955). Cap management will help to release trapped pressure, and remove carbon dioxide. However, degassing with nitrogen gas did not increase fermentation rate in this study (Amerine 1955).

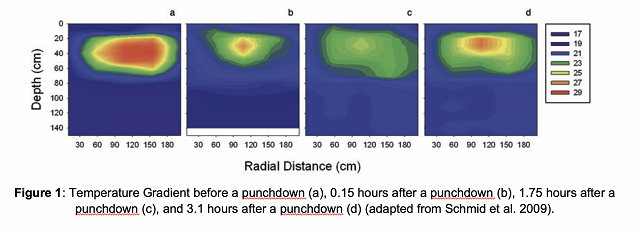

High cap temperatures can increase fermentation rates (Guymon and Crowell 1977). Heat is easily removed from liquid by tank cooling jackets, but is more difficult to control in the cap because it is a poor heat conductor (Boulton et al. 1996). The temperature of the cap, therefore, tends to increase relative to the temperature of the juice due to yeast fermentative action. As fermentation is at its most vigorous rate (using the most sugar), the temperature of the cap and fermentation were at its warmest (Schmid et al. 2009). Thus, cap temperature management is important to help maintain constant fermentation while avoiding heat shock to yeast (Schmid et al. 2009). Temperature gradients in tank can differ by up to 14°C from juice at the bottom fermentor to the core of the cap. Additionally, a gradient of 6-8°C can exist from the core and sides of the cap, with the core being the warmest (Schmid et al. 2009). After a punchdown, temperature gradients dissipate, but often not completely. They then come back after around 3 hours (Figure 1). The smaller the fermentor, the more complete the temperature gradient elimination because of the more efficient mixing from a punchdown/pumpover (Schmid et al. 2009)

These studies do not conclusively indicate that any one method is “better” than another, and much changes depending on factors such as the size and shape of the fermentor, the mechanical pressure of the pumpover or punchdown, the ratio of skin to juice, etc. These practices, therefore, should be individually assessed by each winery for their own particular stylistic and logistical needs. This study examines the impact of different cap management techniques on the chemical and sensory qualities of Merlot wine.

Results and Discussion

Increasing punchdowns and pumpovers increased the pH (5% and 22% lower proton concentration, respectively) and pumpovers slightly decreased TA (possibly due to increased potassium extraction). The treatments also increased the volatile acidity and increased the sulfur dioxide binding capacity of the wine. This may have resulted from an increase in oxygen exposure to wines with these treatments. Increasing the number of punchdowns had the greatest impact on color, catechin, and tannin accumulation, although pumpovers slightly increased this as well. Anthocyanins were decreased by the treatments, especially with the 4 punchdown treatment. This could be due to increased shearing of the skins, allowing for more anthocyanin adsorption back onto skins.

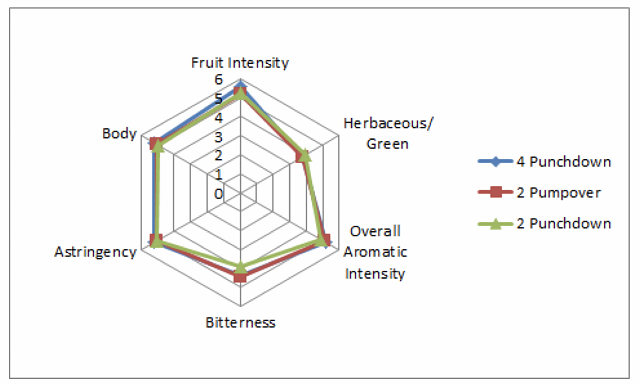

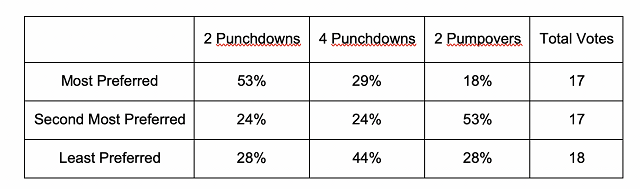

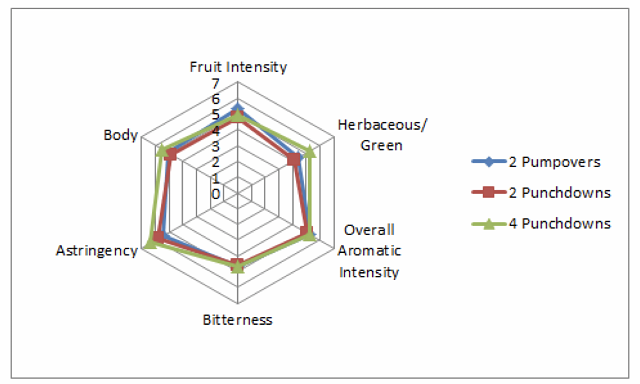

For the April 26 tasting, no strong trends were found with the descriptors used in this study. The 2 Punchdown wine tended to have less Bitterness, but this was a weak tendency. In general, people preferred the 2 punchdown wine, followed by the 2 pumpovers.

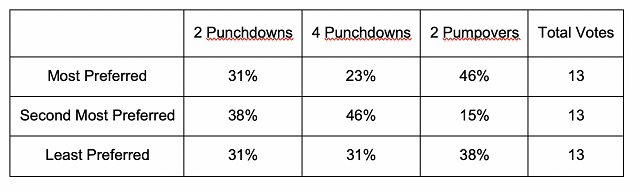

For the May 24 tasting, no strong trends were found for the descriptors used in this study. There was a slight trend for 4 punchdowns to increase Herbaceous/Green character, Astringency, and Body. No preference trends could be seen between wines. One judge had no preference. Most judges were not able to perceive strong differences between the wines.

Overall, these wines were not perceived to be very different from each other. The 2 Punchdown wine seemed to be slightly more preferred than the rest of the treatments, but this was a weak preference. Descriptive analysis from both tastings suggest that the 2 Punchdown wine may have been slightly lower in Astringency, Bitterness, Body, and Herbaceous/Green character. However, if so then this was a very weak trend.

Methods

Identically sourced Merlot grapes (from vineyard V3) were hand-harvested on 9/25 and destemmed and sorted on 9/26 into three separate 1 ton bins for three separate treatments: 2 punch downs/day, 2 pumpovers/day, and 4 punch downs/day. The must was inoculated with 15g/hL D254 and adjusted with 1g/L tartaric acid, to achieve a pH of 3.64. For the two punch downs and two pump overs/day, the time was approximately 5-8 hours apart in between each cap protocol. For the 4 punch downs/day, the time was approximately 1-2 hours in between each punch down. The pumpover length of time was based on the vigor of fermentation, pumping over around 5-10 minutes at the height of fermentation and for only a couple of minutes as the fermentation approached 5 Brix. Punchdowns were meant to submerge the cap without being so vigorous as to excessively shred skins and grind seeds at the bottom of the fermentor, and resulted in around 2 minutes per punchdown. The must was adjusted to a pH of 3.7 with tartaric acid as needed. At 3-5 Brix, all bins received 2 punch downs daily. The three bins were pressed separately on 10/24, into separate containers. 1 g/hL MBR 31 was added at the end of alcoholic fermentation for malolactic conversion. Following pressing, the wines received 2 rackings off lees before barreling into neutral oak. On 10/25, 1g/L tartaric acid was added. Following malolactic conversion, the three lots were treated identically. Each lot received 50 ppm of sulfur dioxide.

This project was tasted on April 26 and May 24. In order to balance the data set to perform statistical analysis for descriptive analysis on the April 26 tasting, any judge who had not fully completed the descriptive analysis ratings were removed. In order to then make the number of judges between groups equivalent, one judge from group 1 was transferred to group 2, and another judge from group 1 was eliminated. This resulted in a final data set of 3 groups, each with 6 judges (considered as replications within groups, and groups were considered as assessors). Data was analyzed using Panel Check V1.4.2. Because this is not a truly statistical set-up, any results which are found to be statistically significant (p<0.05) will be denoted as a “strong trend” or a “strong tendency,” as opposed to general trends or tendencies. The statistical significance here will ignore any other significant effects or interactions which may confound the results (such as a statistically significant interaction of Judge x Wine confounding a significant result from Wine alone). The descriptors used in this study were Fruit Intensity, Herbaceous/Green, Overall Aromatic Intensity, Bitterness, Astringency, and Body.

The same procedures for data analysis were used on the May 24 tasting. For the descriptive analysis in this tasting, one judge had to be moved from group 3 to group 1, and another judge from group 2 and group 3 were eliminated. This resulted in a final data set with each group having four judges, for a total of 12 judges.

References

Amerine, M.A. 1955. Further studies with controlled fermentations. Am. J. Enol. Vitic. 6:1-16.

Baumes, R.L., Bayonove, C.L., Barillere, J.M., Samson, A., and Cordonnier, R.E. 1989. Skin contact in white wine processing – Effects on the volatile constituents of wines. Vitis. 28:31-48.

Bosso, A., Panero, L., Petrozziello, M., Follis, R., Motta, S., and Guaita, M. 2011. Influence of submerged-cap vinification on polyphenolic composition and volatile compounds of Barbera wines. Am. J. Enol. Vitic. 62:503-511.

Boulton, R.B., Singleton, V.L., Bisson, L.F. and Kunkee, R.E. 1996. Principles and practices of winemaking (Chapman & Hall: New York).

Cabaroglu, T., Canbas, A., Baumes, R., Bayonove, C., Lepoutre, J.P., and Günata, Z. 1997. Aroma composition of a white wine of Vitis vinifera L. cv. Emir as affected by skin contact. J. Food. Sci. 62:680-683.

Callejón, R.M., Margulies, B., Hirson, G.D., and Ebeler, S.E. 2012. Dynamic changes in volatile compounds during fermentation of Cabernet Sauvignon grapes with and without skins. Am. J. Enol. Vitic. 63:301-312.

Ferreira, B., Hory, C., Bard, M.H., Taisant, C., Olsson, A., and le Fur, Y. 1995. Effects of skin contact and settling on the levels of the C18:2, C18:3 fatty acids and C6 compounds in Burgundy Chardonnay musts and wines. Food Qual. Pref. 6:35-41.

Fischer, U., Strasser, M., and Gutzler, K. 2000. Impact of fermentation technology on the phenolic and volatile composition of German red wines. Int. J. Food. Sci. Tech. 35:81-94.

Guymon, J.F. and Crowell, E.A. 1977 The nature and cause of cap-liquid temperature differences during wine fermentation. American Journal of Enology and Viticulture 28:74–78.

Mansfield, A.K., Schirle-Keller, J.P., and Reineccius, G.A. 2011. Identification of odor-impact compounds in red table wines produced from Frontenac grapes. Am. J. Enol. Vitic. 62:169-176.

Moyano, L., Moreno, J., Millan, C., and Medina, M. 1994. Flavour in “Pedro Ximénez” grape musts subjected to maceration processes. Vitis 33:87-91.

Ramey, D., Bertrand, A., Ough, C.S., Singleton, V.L., and Sanders, E. 1986. Effects of skin contact temperature on Chardonnay must and wine composition. Am. J. Enol. Vitic. 37:99-106.

Sacchi, K.L. Bisson, L.F., and Adams, D.O. 2005. A review of the effect of winemaking techniques on phenolic extraction in red wines. Am. J. Enol. Vitic. 56:197-206.

Schmid, F., Schadt, J., Jiranek, V., and Block, D.E. 2009. Formation of temperature gradients in large- and small-scale red wine fermentations during cap management. Australian Journal of Grape and Wine Research. 15:249-255.

Selli, S., Cabaroglu, T., Canbas, A., Erten, H., and Nurgel, C. 2003. Effect of skin contact on the aroma composition of the musts of Vitis vinifera L. cv. Muscat of Bornova and Narince grown in Turkey. Food Chem. 81:341-347.

Zoecklein, B. 2002a. Red wine phenolic management. Enology Notes #61. http://www.apps.fst.vt.edu/extension/enology/EN/61.html.

Zoecklein, B. 2002b. Red wine phenolic management, continued. Enology Notes #62. http://www.apps.fst.vt.edu/extension/enology/EN/62.html.