Carbonic Maceration in Norton (2017)

Mark Patterson

Chrysalis Vineyards

Summary

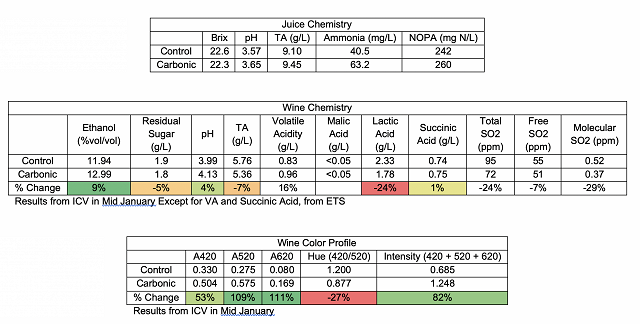

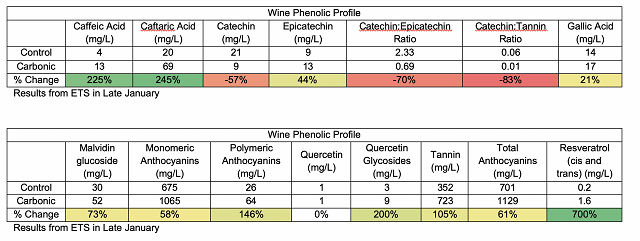

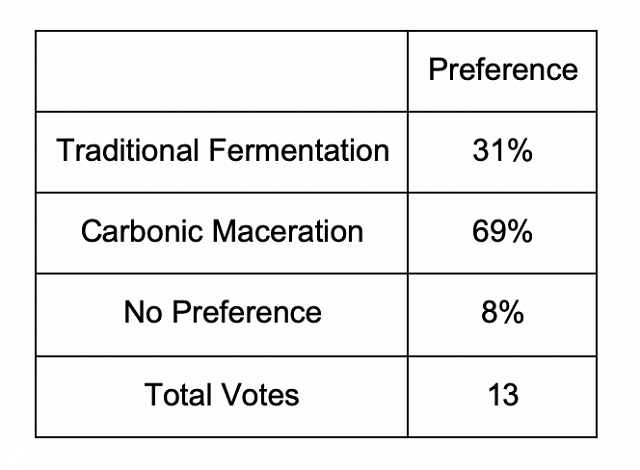

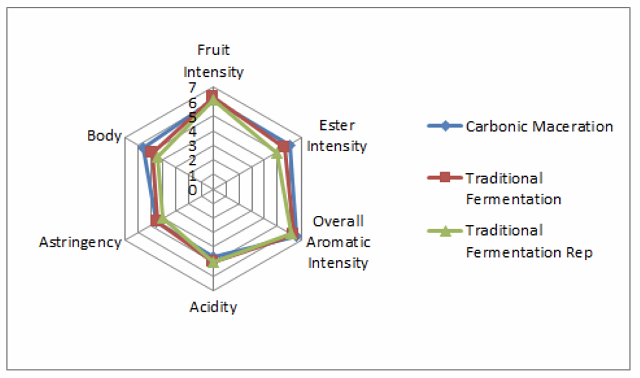

This study examines the impact of different winemaking styles on resulting Norton wine. Norton grapes were harvested over two days, and on the first day whole cluster, undamaged grapes were placed into a CO2-purged stainless steel tank with dry 71B yeast on the bottom (this yeast promotes ester formation) while on the second day grapes were destemmed and crushed into multiple T bins. This carbonic maceration tank was gassed with carbon dioxide daily throughout the maceration (approximately 17 days) and held at 65°F. The grapes were then pressed on November 6, and the press fraction was separated, inoculated, and fermented to dryness. The other treatment was punched down twice per day in T Bin throughout fermentation, and the T bins were inoculated with a mix of Lalvin C and Clos yeasts. The T Bins were pressed off on November 3. The carbonic maceration wine has higher alcohol, pH, and VA, with lower TA and lactic acid. The carbonic maceration wine has higher color and phenolic parameters, except for catechin. In sensory analysis, 58% of judges were able to correctly distinguish the wines, suggesting that the wines were significantly different (p<0.01). People who were able to distinguish the wines tended to prefer the carbonic maceration wine. There was a strong trend for the carbonic maceration wine to have higher Body than the traditional fermentation wine. There was a slight tendency for the carbonic maceration wine to have higher Ester Intensity. More studies should be performed on carbonic maceration in Norton and other non-vinifera grape varieties. Additionally, more studies should examine the evolution of aroma and flavor of these wines over time, and how this impacts overall consumer preference.

Introduction

Carbonic maceration produces wines that are often characterized by their aromatic richness, softness, and balance. Generally these wines are characterized by intense estery and fruity notes at first, which quickly decline over time. Carbonic maceration occurs when unbroken berries (either destemmed or whole cluster) are held in a tank for an extended period of time under an inert gas atmosphere (often carbon dioxide). It has been recommended that this time be from 5-8 days at 30-32°C, but this can vary widely depending on the style of wine desired. Glucose and malic acid is degraded inside the berry through anaerobic grape enzymatic reactions (intracellular fermentation). Malic acid can be degraded by up to half in this process, and about 1.5%-2% alcohol is formed. A con-current yeast fermentation occurs in the free run juice, and often submerged grapes do not themselves undergo carbonic maceration (often because they are damaged from the weight of berries on top of them). Instead, the grapes which are only submerged in a carbon dioxide atmosphere themselves undergo maceration. Grapes are then pressed, and often the free run wine is kept separate from the press fraction juice in order to avoid lactic disease. This press fraction juice retains the carbonic maceration character and must undergo a secondary yeast fermentation to complete alcoholic conversion of the sugars. Carbonic maceration wines generally have lower ethanol, titratable acidity, anthocyanins, and tannin, and have higher pH. They are also often characterized by higher succinic acid and succinic acid esters (Tesniere and Flanzy 2011). This study examined the impact of carbonic maceration on the chemical and sensory qualities of Norton in comparison to traditional fermentation.

Results and Discussion

The carbonic maceration wine had higher alcohol, pH, and VA, with lower TA and lactic acid. The carbonic maceration wine also had higher color and phenolic parameters, except for catechin. These results are unusual for carbonic maceration wines.

For the triangle test, of 24 people who answered, 14 people chose the correct wine (58%), suggesting a statistically significant difference between wines (p<0.01). These wines were voted to have an average degree difference of 4.6 (out of 10), suggesting that the wines were moderately different. In general, people who answered correctly preferred the carbonic maceration wine to the traditional fermentation. For the descriptive analysis, there was a strong trend for the Carbonic Maceration wine to have higher Body than the Traditional Fermentation wine (LSD=0.81). There was a slight tendency for the carbonic maceration wine to have higher Ester Intensity.

The results in this study differ from more traditional carbonic maceration studies. Although this study agrees with the literature in that acidity was lowered by carbonic maceration (with a concomitant rise in pH) due primarily to malic acid consumption, the subsequent increase in ethanol is unusual. Additionally, succinic acid is generally increased by carbonic maceration, which is not seen here. Furthermore, the general increase in phenolic compounds and color by carbonic maceration is unusual, although this can occur depending on winemaking techniques (Tesniere and Flanzy 2011). These differences may be due in large part to the different yeast strains used in this study (the yeast strains were chosen to favor the characteristics desired for each style of wine), or the impact of traditional winemaking practices on a non-vinifera grape such as Norton compared to more common grape varieties. More studies should be performed on carbonic maceration in Norton and other non-vinifera grape varieties. Additionally, more studies should examine the evolution of aroma and flavor of these wines over time, and how this impacts overall consumer preference.

Methods

Approximately 18 tons of Norton were sourced from the same vineyard over the course of 2 consecutive days for this project.

Carbonic Maceration

On October 20, 2017, 9,918 pounds of whole cluster, hand-picked Locksley Estate Norton was dumped into a 3300 gallon stainless steel tank. The tank was purged with carbon dioxide prior to Norton addition. 10g/hL 71B yeast (dry) was at the bottom of the tank prior to addition of grapes. The tank was gassed with carbon dioxide every day during the carbonic maceration. The temperature was held at around 65°F for the duration of the fermentation. The tank was drained and pressed on November 6, and the press run was separated and inoculated with 15g/hL 71B on November 7, 2017 (rehydrated with 20g/hL Energy GLU). The fermentation occurred at 58°F for 7 days. The wine was then racked to a mix of French, Hungarian, and Virginia Oak barrels (a mix of 1st to 3rd fill) on November 16. Wine was inoculated with 50% PN4, 20% Alpha, and 30% MBR31 for malolactic fermentation on November 27. 66ppm sulfur dioxide was added on January 13.

Traditional Fermentation

On October 21, 8,945 pounds of Locksley Estate Norton was destemmed and crushed into 5 one ton T bins, with 60ppm sulfur dioxide added at crush. Must received 100mL/ton Color Pro and 3 pounds per bin of untoasted French oak dust from Nadalie. 3 Bins were inoculated with 25g/hL Lalvin C, and 2 bins were inoculated with 25g/hL Clos on October 21, 2017. The yeasts were rehydrated with 30g/L GoFerm. 20g/hL FT Berry was added to all bins on October 22. T Bins were punched down twice per day throughout fermentation at 12 hour intervals. Fermented at ambient cellar temperature, with a high temperature of 78°F. On October 24, 25g/hL Fermaid K was added to each bin at around 16 Brix. The wine was pressed on November 3 at around 0.5 Brix and racked into a mix of French, Hungarian, and American Oak barrels (a mix of 1st to 4th fill barrels) on November 7. Malolactic bacteria was added on November 10 (40% PN4 and 60% Alpha).

Sensory Analysis

This wine was tasted on February 7, 2018. For the triangle test, descriptive analysis, and preference analysis, anybody who did not answer the form were removed from consideration for both triangle, degree of difference, and preference. Additionally, anybody who answered the triangle test incorrectly were removed from consideration for degree of difference and preference. Additionally, any data points for preference which did not make sense (such as a person ranking a wine and its replicate at most and least preferred, when they correctly guessed the odd wine) were removed.

In order to balance the data set to perform statistical analysis for descriptive analysis, any judge who had not fully completed the descriptive analysis ratings were removed. In order to then make the number of judges between groups equivalent, two judges from group 3 were transferred to group 1, and another judge from group 3 was eliminated. This resulted in a final data set of 3 groups, each with 7 judges (considered as replications within groups, and groups were considered as assessors). Data was analyzed using Panel Check V1.4.2. Because this is not a truly statistical set-up, any results which are found to be statistically significant (p<0.05) will be denoted as a “strong trend” or a “strong tendency,” as opposed to general trends or tendencies. The statistical significance here will ignore any other significant effects or interactions which may confound the results (such as a statistically significant interaction of Judge x Wine confounding a significant result from Wine alone). The descriptors used in this study were Fruit Intensity, Ester Intensity, Overall Aromatic Intensity, Acidity, Astringency, and Body.

References

Tesniere, C. and Flanzy, C. 2011. Carbonic maceration wines: Characteristics and winemaking process. In: Advances in Food and Nutrition Research, Vol 63. Ed. Ronald S. Jackson. Burlington: Academic Press. pp. 1-15.