Strategies to minimize spoilage in ambient fermentations of Cabernet Franc: chitosan, cold soak (2020)

Todd Henkle

The Vineyards and Winery at Lost Creek

Summary

At the Vineyards and Winery at Lost Creek, red wines have been fermented without the addition of commercial yeast since 2016. The purpose of this experiment was to explore three approaches to fermentation to reduce volatile acidity and maintain complexity in ambient fermented wines: cold soak, no cold soak, and chitosan treatment (with Enartis Stab Micro M). Limiting cold soak reduced the population of Hanseniaspora 10-fold, but did not lead to reductions in ethyl acetate or acetic acid in the finished wine. Use of Stab Micro M at a low dose also had no measurable effect. Acetic acid values increased considerably during malolactic fermentation, providing a potential future target for limitation.

Introduction

At the Vineyards and Winery at Lost Creek, red wines have been fermented without the addition of commercial yeast since 2016. They believe that the greater diversity in the microbial population during ambient fermentation leads to more complex finished wines. However, ambient fermentation also includes a greater level of risk, and can lead to elevated levels of acetic acid and ethyl acetate. The purpose of this experiment was to explore three approaches to fermentation for their effects on volatile acidity and complexity in ambient fermented wines.

In one treatment, the standard protocol of the winery was used; a TBin of processed must was cold soaked with CO2 gassing in a refrigerator for two days prior to placement in the cellar for fermentation. A second treatment did not include cold soak, but rather moved the bin to the cellar directly after processing. Cold soak is generally done to increase extraction of compounds into an aqueous medium (before ethanol is present)1. This approach is thought by some to produce fruitier wines with stronger color and smoother tannins1. Some also feel it enhances aromatic complexity2. Several academic studies have failed to find differences in anthocyanins and tannins with cold soak while others have reported benefits1,2. Inconsistency in the literature on the effects of cold soak are likely due to several other confounding factors such as variety, ripeness, other cellar operations such as cap management, temperature, etc. It is therefore useful to explore these effects on local grapes in your own cellar conditions.

Another potential effect of cold soak is the activity of non-Saccaromyces yeast. These yeast may have a positive impact on aroma and flavor complexity by releasing flavor precursors that Saccharomyces later transform. They can also increase fruity aromas through the production of significant amounts of esters1. However, they may also have negative sensory effects. Hanseniaspora (AKA Klockera) is the main species found on mature grapes, which can produce positive compounds as described above, however this cryotolerant yeast can also produce large amounts of ethyl acetate and acetic acid2,3. For a broader discussion of non-Saccharomyces yeast, see the Learn section of the WRE website.

One approach to limiting spoilage organisms is the use of Stab Micro M, a chitosan-based product developed specifically for use during fermentation. Chitosan binds in different degrees to different microbes based on the chemical properties of the cell wall itself, with high degree of correlation to the hydrophilicity of the wall4. Chitosan has been shown to have some efficacy against a wide range of grapevine and wine microbes including downy mildew5, powdery mildew6, Phomopsis7, Lactobacillus, Oenococcus, and Brettanomyces4. Gram negative bacteria are more susceptible to binding than gram positive4. Due to its versatility as an antimicrobial agent, chitosan in various forms has been used worldwide at nearly every stage of wine production including vineyard applications, on grapes during transport and storage, at crush, after fermentation and during the aging of wine8–10.

Most chitosan products are recommended for use in finished wine. Stab Micro M (Enartis) is a chitosan-based product specially formulated for use on juice and must to reduce the activity of a wide range of microbes, leading to reduction in volatile acidity, sulfide defects, volatile phenols and production of other off-flavors. It can be used in conjunction with SO2 or as a replacement, depending on the condition of grapes and preference of the winemaker8. In this experiment, a third TBin of processed fruit was treated with a low dose of Stab micro M, then cold soaked prior to warming for fermentation. Due to its anti-microbial effects, chitosan may decrease the production of volatile acidity, but may also reduce complexity in the wine. Also, due to the large populations of microbes in grape must, chitosan at its recommended dose may have no effect at all.

Methods

Fruit was hand harvested and grapes were refrigerated overnight prior to processing. Fruit was sorted then destemmed into three Tbins with 15% whole clusters and the remaining 85%whole berry. There were three treatments in this experiment:

-

One bin was covered in plastic, gassed with CO2, and returned to the refrigerator for 2 days of cold soak.

-

One bin was covered in plastic, gassed with CO2, and brought into the cellar (no cold soak).

-

In a third bin, 3 g/hL Stab Micro M was sprinkled throughout the fruit during processing. This bin was covered in plastic, gassed with CO2, and put in the refrigerator for cold soak.

All three bins also received 40 ppm SO2 during processing. A 10% saignée was done on each bin, with removal of 55 liters of juice. At the end of cold soak (bins 1 and 3), bins were brought into the cellar and allowed to warm for ambient fermentation. A juice sample was taken from each bin for microbiological analysis at the time of placement in the cellar. Samples were sent to ETS labs in California for microbiological analysis. Tartaric acid additions were made to a common target pH with bin 1 receiving 2.6 g/L, bin 2 receiving 2.5 g/L and bin 3 receiving 2.7 g/L.

Bins were lightly punched down and gassed until signs of fermentation began, after which they received three punchdowns daily. Bins were actively heated between 19 and 9° Brix and macerated for a total of 29 days prior to pressing. After pressing, wine was allowed to settle, then transferred to comparable oak barrels for malolactic fermentation. Wine from treatment 1 completed malolactic fermentation by December without inoculation. Wine from treatments 2 and 3 was inoculated with VP41 malolactic bacteria in December and completed malolactic fermentation in early January. Wine was treated with 70 ppm SO2 at the completion of malolactic fermentation.

Results

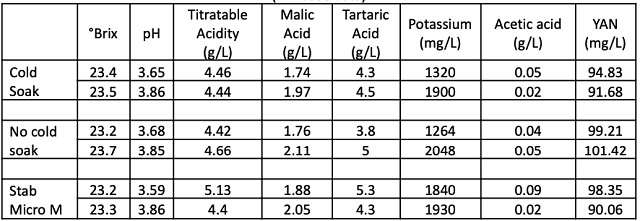

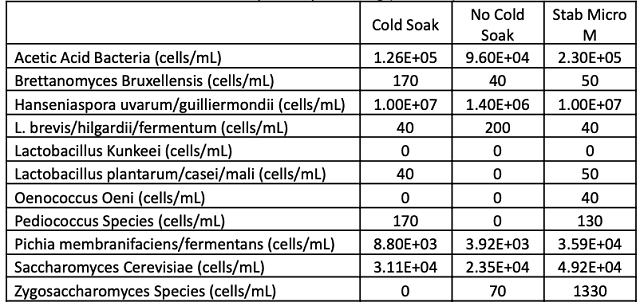

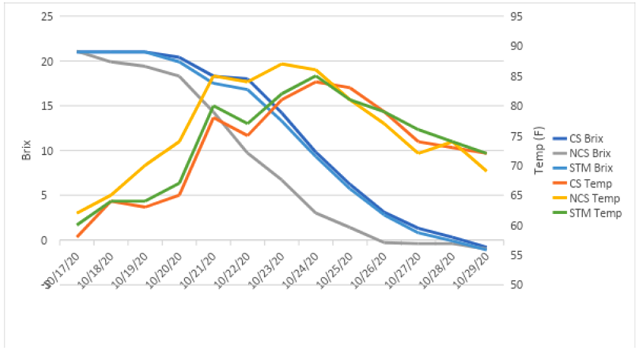

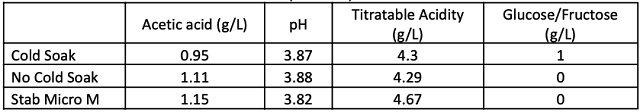

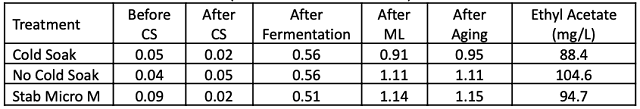

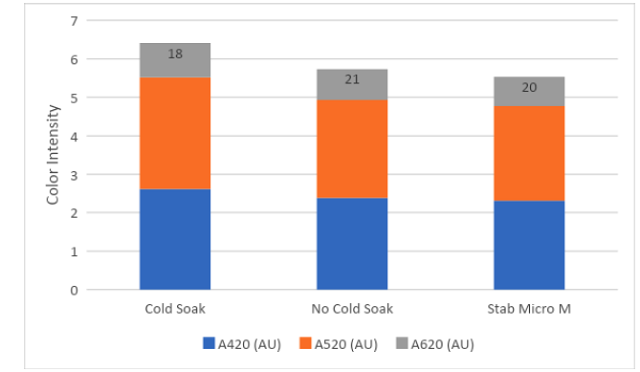

The general chemistry of must was very similar among bins, with pH and potassium increasing after cold soak (Table 1). Addition of Stab Micro M did not notably affect the microbial population after cold soak (Table 2), while the must that was not sold soaked had 10x fewer Hanseniaspora colonies. All three fermentations proceeded in a rigorous fashion; the bin that was not cold soaked started several days sooner, however, the cold soaked bins fermented at a similar pace once they started (Figure 1). Finished wine chemistry was also similar among treatments (Table 3). Treatments 1 and 3 both received cold soak, with no consistent effect on color (Figure 2). Each of the fermentations produced wines with notably high volatile acidity, which accumulated both during alcoholic and malolactic fermentation (Table 4). Lower Hanseniaspora population in the non-cold soaked bit did not lead to lower ethyl acetate. Ethyl acetate levels in each bin were within the range of sensory detection (Table 4). The dose of Stab Micro M used this this experiment (3 g/hL) was lower than the recommended dose for fermenting must (10-30 g/hL). It may be necessary to use higher dose rates to see effects. Also, accumulation of volatile acidity during malolactic fermentation may be a good target for spoilage reduction without effects on complexity.

Table 1: Fruit chemistry for three treatments of ambient fermentation Cabernet Franc

(in-house data)

Table 2: Microbiology of fruit for three treatments of ambient fermentation Cabernet Franc taken 2 days after processing (ETS Labs)

Figure 1: Fermentation kinetics for three treatments of ambient fermented Cabernet Franc

(in-house data)

Table 3: Finished wine chemistry for three treatments of ambient fermentation Cabernet Franc (ICV Labs)

Table 4: Evolution of acetic acid (g/L) for three treatments of ambient fermented Cabernet Franc (in-house data and ICV labs)

Figure 2: Color metrics for three treatments of ambient fermented Cabernet Franc (ICV labs). Values in endcaps indicate free SO2 at the time of sampling.

References

(1) Razungles, A. Extraction Technologies and Wine Quality. In Managing Wine Quality: Volume 2 – oenology and wine quality; Woodhead Publishing: Cambridge, 2010; Vol. 2.

(2) Jackson, R. S. Wine Science: Principles and Applications, 4 edition.; Academic Press: Amsterdam, 2014.

(3) Diversity of Wine Yeasts | Viticulture and Enology. https://wineserver.ucdavis.edu/industry-info/enology/wine-microbiology/yeast-mold/diversity-wine-yeasts (accessed 2018-11-13).

(4) Chung, Y.; Su, Y.; Chen, C.; Jia, G.; Wang, H.; Wu, J. C. G.; Lin, J. Relationship between Antibacterial Activity of Chitosan and Surface Characteristics of Cell Wall. Acta Pharmacol Sin 2004, 5.

(5) Romanazzi, G.; Mancini, V.; Feliziani, E.; Servili, A.; Endeshaw, S.; Neri, D. Impact of Alternative Fungicides on Grape Downy Mildew Control and Vine Growth and Development. Plant Disease 2016, 100 (4), 739–748.

(6) Iriti, M.; Vitalini, S.; Di Tommaso, G.; D’Amico, S.; Borgo, M.; Faoro, F. New Chitosan Formulation Prevents Grapevine Powdery Mildew Infection and Improves Polyphenol Content and Free Radical Scavenging Activity of Grape and Wine: Grape Powdery Mildew Control by Chitosan. Australian Journal of Grape and Wine Research 2011, 17 (2), 263–269.

(7) Nascimento, T.; Rego, C.; Oliveira, H. Potential Use of Chitosan in the Control of Grapevine Trunk Diseases. Phytopathologia Mediterranea 2007, 46 (2), 8.

(8) Barrett, L. Microbial Stability and Control: EnartisStab Micro (Chitosan) Application during Wine Maturation, 2019.

(9) Singh, R. K.; Martins, V.; Soares, B.; Castro, I.; Falco, V. Chitosan Application in Vineyards (Vitis Vinifera L. Cv. Tinto Cão) Induces Accumulation of Anthocyanins and Other Phenolics in Berries, Mediated by Modifications in the Transcription of Secondary Metabolism Genes. IJMS 2020, 21 (1), 306.

(10) Singh; Soares; Goufo; Castro; Cosme; Pinto-Sintra; Inês; Oliveira; Falco. Chitosan Upregulates the Genes of the ROS Pathway and Enhances the Antioxidant Potential of Grape (Vitis Vinifera L. ‘Touriga Franca’ and ’Tinto Cão’) Tissues. Antioxidants 2019, 8 (11), 525.