Developing a protocol for whole cluster fermentation in Cabernet Franc (2020)

Tim Gorman

Cardinal Point

Summary

In 2019, Matthieu Finot from King Family Vineyards shared a protocol for whole cluster fermentation in Petit Verdot that allowed for robust beginning of fermentation, minimized spoilage, and produced a rustic, powerful wine. The purpose of this experiment was to apply a similar methodology to the fermentation of Cabernet Franc at Cardinal Point. Grapes were processed without chilling into TBins with (1) destemming (2) 50% destemmed, 50% whole clusters and (3) 50% whole clusters foot stomped, 50% whole clusters. Whole cluster inclusion led to slower start to fermentation, higher concentration and perception of tannin, higher measured and perceived color, and no increases in volatile acidity beyond sensory thresholds. The methodology was transferable from Petit Verdot at King Family to Cabernet Franc at Cardinal Point.

Introduction

Utilizing whole clusters rather than destemmed or crushed fruit has several effects on the resulting wines with several chemical processes at play. Anaerobic metabolism inside the grape can lead to loss of malic acid, increase in some fruity aromas and flavors and loss of some varietal character1–3. Some fruity aromas and flavors are retained inside berries that would otherwise be lost to volatilization during fermentation3. Inclusion of stems can lead to some loss of color, increases in potassium (with drop in acid), and potential increases in phenolics such as catechin and tannin4. Whole cluster fermentations are often cooler than traditional fermentations and it takes longer for a cap to form. Cap management after berries begin to break down is more successful at breaking up the cap fully due to less compaction of berries and stems1,4. There is often less extraction of phenolics from skins and seeds as there is less contact time for alcohol-based solubilization1. The extent of each of these effects depends on the proportion of whole clusters, and whether those clusters are surrounded by air or fermenting juice.

Whole cluster fermentations also include pockets of oxygen that can persist for some time, allowing for spoilage by aerobic yeast and bacteria. Some whole cluster fermentations are characterized by acetic acid and ethyl acetate, leading to aromas of vinegar and nail polish remover1. However, these fermentations can also lead to increased complexity with higher levels of phenolics. For a more in-depth review of carbonic maceration and whole cluster fermentations, see the Learn section of the Winemakers Research Exchange website.

In 2019, Matthieu Finot from King Family Vineyards shared a protocol for whole cluster fermentation in Petit Verdot that allowed for robust beginning of fermentation, minimized spoilage, and produced a rustic, powerful wine. This protocol includes several important elements:

-

Processing grapes without chilling. This allows the rapid onset of fermentation needed to produce CO2 to displace oxygen and prevent production of acetic acid and ethyl acetate.

-

Beginning the fermentation by foot stomping clusters at the bottom of the bin to produce juice

-

Adding a source of yeast, either a starter culture from another fermentation or rehydrated commercial yeast, to this juice to begin fermentation quickly.

The purpose of this experiment was to apply a similar methodology to the fermentation of Cabernet Franc at Cardinal Point.

Methods

Cabernet Franc grapes from Silver Creek Vineyards were hand harvested and processed without chilling. Each TBin received 0.75 tons of fruit.

Treatment #1: Grapes were destemmed to TBin.

Treatment #2: 50% of the fruit (by weight) was destemmed to TBin, then the remaining fruit was loaded as whole clusters on top.

Treatment #3: 50% of the fruit (by weight) was loaded into TBin with foot stomping, then the remaining fruit was loaded as whole clusters on top.

All three bins were inoculated with 25 g/hL BM45 yeast. No other additions were made at this time. All three bins were gassed until fermentation began, then monitored for density depletion each day. All three bins showed signs of fermentation by the third day post inoculation, and were chaptalized with 30 g/L sugar. Fermaid O (40 g/hL) was also added at this time. Cap management occurred twice per day, either by punching down or foot stomping as needed. All bins were pressed on 10/19, after all lots had completed fermentation. Wine was inoculated for malolactic fermentation with CH41 and completed malolactic fermentation in barrel.

Sensory analysis was completed by a panel of 32 wine producers. Due to restrictions put in place during COVID-19, sensory analysis was completed using shipped samples. Each wine producer received three wines in identical bottles, filled on the same day, each coded with random numbers. Two of the bottles contained the same wine while the third bottle contained the different wine. Participants were asked to identify which wine was different (a triangle test). There were four tasting groups with the unique wine in the triangle test balanced among the groups. Participants were then asked to score each wine on a scale of 0 to 10 for color intensity, fruit character, perception of tannin, and herbaceous/green character. They were also given open ended questions to describe the wines. Results for the triangle test were analyzed using a one-tailed Z test. Descriptive scores were analyzed using repeated measures ANOVA.

Results

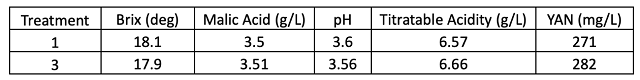

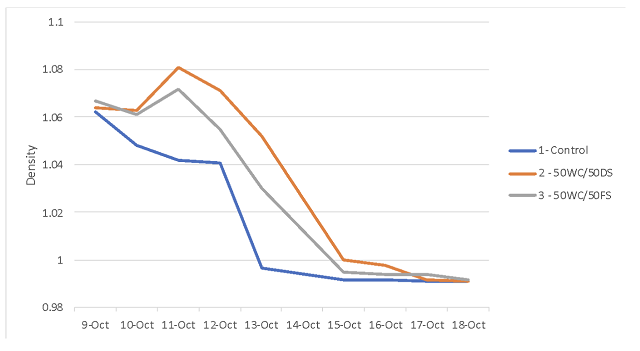

Fruit chemistry was measured for treatments 1 and 3 only; all metrics were very similar (Table 1). Inclusion of whole clusters led to slower overall start to fermentation, but the fermentation was steady once it had begun (Figure 1).

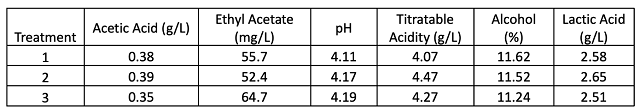

Volatile acidity is a common fault found in whole cluster fermentations, and can be characterized by both acetic acid and ethyl acetate. While acetic acid smells like vinegar, ethyl acetate smells like nail polish remover, glue or varnish, but only above its sensory threshold, which ranges from 90-150 mg/L. Below this threshold, ethyl acetate can lend richness and sweetness to wines, and improve complexity6. Addition of whole clusters in this experiment did not lead to higher acetic acid and only slightly higher ethyl acetate (Table 2). One of the reasons to stomp fruit at the bottom of the bin and start the fermentation quickly is to produce enough CO2 to flush out oxygen. That appears to have been a successful strategy, here.

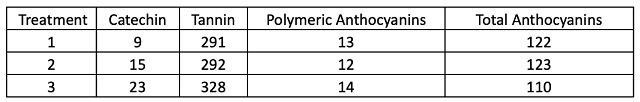

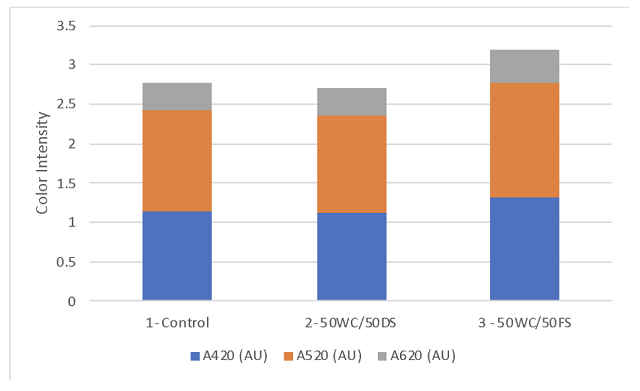

The effect of higher stem content can be seen in several of the wine metrics. pH values increased as stem content increased, likely due to potassium leaching from stems (Table 2). Stems contain tannins and tannin subunits such as catechin. Catechin increased proportionally with increased stem inclusion. Tannins only increased with treatment 3 (Table 3). Though anthocyanin values were lowest in treatment 3 (Table 3), color intensity (Figure 2) and perception (Table 4) were highest in this treatment, demonstrating the complexity of color expression in wine.

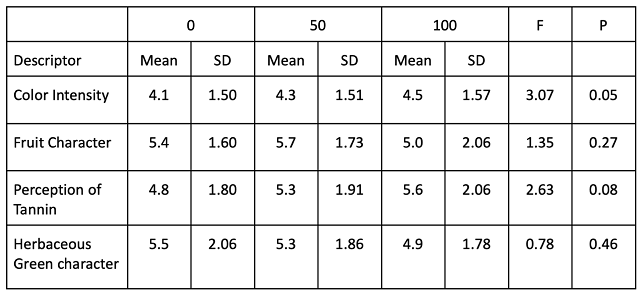

There were no significant differences in scores for any of the metrics scored in blind sensory analysis, however perception of color and tannin both increased with increasing inclusion of whole clusters, and were nearly significant (Table 4).

Table 1: Fruit chemistry for two treatments of Cabernet Franc (VaTech Enology Services Lab)

Figure 1: Fermentation kinetics for three treatments of Cabernet Franc (in-house data)

Table 2: Wine chemistry for three treatments of Cabernet Franc (ICV Labs)

Table 3: Phenolic measurements for three treatments of Cabernet Franc (mg/L) (ICV Labs)

Figure 2: Color metrics for three treatments of Cabernet Franc before SO2 (ICV labs)

Table 4: Statistical analysis for descriptive scores from blind sensory analysis of Cabernet Franc

References

(1) Jackowetz, N.; Li, E.; de Orduña, R. M. Sulphur Dioxide Content of Wines: The Role of Winemaking and Carbonyl Compounds. Appellation Cornell 2011, 3, 1–7.

(2) Tesniere, C.; Flanzy, C. Carbonic Maceration Wines: Characteristics and Winemaking Process. Adv. Food Nutr. Res. 2011, 63, 1–15.

(3) Bisson, L. F. Grape and Must Processing. In Introduction to Wine Production Course; Davis, California, n.d.

(4) Goode, J. Stemming the Tide. The World of Fine Wine 2012, No. 37, 90–97.

(5) Jackson, R. S. Wine Science: Principles and Applications, 4 edition.; Academic Press: Amsterdam, 2014.

(6) ETS. Ethyl Acetate. ETS.