Stabulation in Rosé (2024)

Wineworks Team

Michael Heny, Alec Bonnoront, & Jessie Handy

Summary

The purpose of this experiment was to test if stabulation could be used to increase aromatic complexity during production of a reserve Rosé. Stabulation is a technique of stirring juice lees at cold temperatures prior to fermentation to increase the extraction of thiol and ester precursors. In this experiment, Merlot juice was pressed after overnight skin contact, then either cold settled immediately after pressing (control) or held for seven days under CO₂ with daily stirring before racking (stabulation). The finished wines had very similar wine chemistry, with both containing thiols and fruity esters at concentrations well above threshold. The control wine showed higher concentration of 3MH (citrus) while the stabulated wine had higher concentration of 3MHA (passionfruit, gooseberry), though sensory differences could not be confirmed as the wines were blended prior to panel evaluation. The logistical considerations and several factors crucial for stabulation success are also discussed.

Introduction

Pippin Hill Farm, a contract winemaking client of Michael Shaps Wineworks, would like to add a reserve Rosé product to their lineup. Both the existing Rosé and the reserve product will be sourced from an 11 ton lot of Clover Green Merlot. One way to differentiate the two products may be the use of stabulation to increase aromatic intensity and complexity in the reserve wine product.

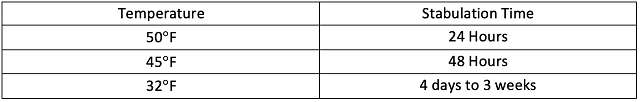

Stabulation is a technique of stirring juice lees for several days to increase the extraction of flavor precursors from the pulp. Originally developed in Provence for use in Rosé winemaking1, this technique has been shown to increase the aromatic extraction of both thiol and ester precursors. When considering stabulation, it is important to hand harvest good quality fruit to prevent microbial activity and protect juice from oxygen with inert gas or dry ice. After pressing, lees are anaerobically stirred, often with CO2, to extract thiol and ester precursors. Wine is kept very cold to prevent fermentation, but low temperature also requires longer time for extraction (Table 1). After stabulation, juice is allowed to settle before racking, warming, and inoculating for fermentation2.

One of the main aims of stabulation is the extraction of aromatic thiols, a specific class of sulfur containing compounds that are responsible for tropical fruit aromas. Though they are only present in low concentrations (they are measured in nanograms, which is 10-9 grams!), they also have very low detection thresholds3,4. Most often associated with Sauvignon Blanc varietal character3 (think broom, boxwood, cat pee, grapefruit), this class of compounds has also been shown to be important in the varietal character of Chardonnay, Petit Manseng, Merlot, Cabernet Sauvignon and Cabernet Franc, among others5. Thiols are also important contributors to the aromas of Rosé. The character of Provençal style Rosé is partially determined by the presence of thiols in the wine1.

There are many steps in the production of wine that affects thiol expression, including interventions in the vineyard as well as the winery. Thiol expression begins with the extraction of precursors from juice pulp (stabulation); however, full expression also includes release of aromatic thiols from their precursors using a yeast strain with B-lyase activity. Thiols are very oxygen sensitive, so both juice and wine must be well protected from oxidation. Protective measures include CO2 gassing prior to fermentation, judicious use of SO2 (never dipping below 20 ppm post fermentation), keeping tanks topped, and limiting oxygen ingress during all winemaking operations. The WRE website has a Learn Module with several articles and experiments about Varietal Thiols in Wine.

In addition to building thiols, stabulation can also increase the concentration of esters in wine, which are significant contributors to fruit and floral aromas including apple, banana, pear, rose, and honey. Stabulation may also improve production logistics as it allows for sequential presses of fruit off a large vineyard, with juice added to the tank over several days. This alleviates very long press days for large lots of Rosé. The purpose of this experiment was to test the impact of stabulation on aromatic complexity for use in production of a reserve Rosé for Pippin Hill Farm.

Table 1: Stabulation can be done at a range of time/temperature combinations2

Methods

Merlot fruit from the Clover Green Vineyard was hand harvested on 8/16/24, destemmed on 8/17/24 and cold soaked overnight (15-18 hours), then pressed to tank on 8/18/24. Cinn Free (20 mL/ton) was added during destemming, with 30 ppm SO2 and an additional 20 mL/ton Cinn Free added at pressing. The following day, lees were stirred, and 2000 L of wine was transferred to a different tank for stabulation. Both tanks received an addition of 1 g/L tartaric acid one day post pressing. Juice samples were analyzed in-house after pressing (pre-clarification), including Brix, pH, TA, and NTU to ensure that wine chemistry was the same between treatments.

Both tanks were chilled. For the control, juice was cold settled for one day, then racked to the fermentation tank. The stabulated juice was chilled and anaerobically stirred by CO2 bubbling daily for 2 minutes followed by blanketing with CO2 (stabulation). Each day, temperature and Brix were monitored to ensure fermentation had not begun. After 7 days, the tank was allowed to settle for one day prior to racking to the fermentation tank. Cellar staff noted that the juice was well-settled at racking, with minimal volume loss. However, an additional note indicated a small amount of fermentation may have occurred during stabulation. The first day of stabulation treatment, the juice was 60°F in the morning but had chilled to 51.3°F by the evening, and remained under 45°F the remainder of the treatment. A second sample was analyzed in-house at racking for each treatment, including Brix, pH, TA, NTU, and YAN. Turbidity in the stabulated tank matched that of the control tank, so no NTU adjustment was needed.

Juice from both treatments was inoculated with .2 g/L Rhone 4600, a thiol-producing yeast, rehydrated in .15 g/L Go Ferm on the day of racking (on 8/19 for the control wine and 8/25 for the stabulated wine). At approximately 2/3 Brix depletion, fermentations received .25 g/L Fresharom (a glutathione product) and .03 g/L Superfood. At 50% Brix depletion, .03 g/L Superfood and .02 g/L DAP were added. Fermentation kinetics (Brix and temperature) were monitored and recorded daily. When wines complete fermentation, 50 ppm SO2 was added. Monthly monitoring measured free SO2 with additions made to a target of >25 ppm free SO2 to retain thiols.

Results

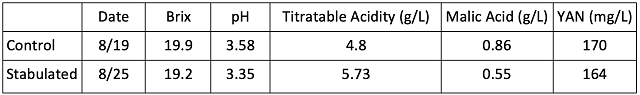

Table 2: Juice Chemistry at racking for two treatments of Rosé (Imbibe solutions)

Juice chemistry was measured at racking, on 8/19 for the control wine and 8/25 for the stabulated wine (Table 2). There is a notable difference in pH between the tanks. Juice in both tanks was acidulated the same day (8/19), however, the control tank had not yet been acidulated when the sample was taken. In-house measures confirm that acidulation was completed in both tanks by the end of the day on 8/19/24 to very similar pH and TA. There is also a notable decrease in malic acid in the stabulated juice. When the juice was first transferred to the stabulation tank, the juice temperature the first day was 60°F, and glycol lines were discovered to be off. Once the glycol was turned on, the juice chilled quickly, however, some malic acid depletion may have occurred by ambient LAB during this time.

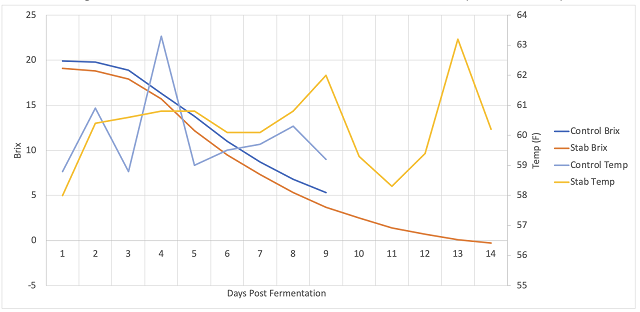

Figure 1: Fermentation kinetics for two treatments of Rosé (in-house data)

Fermentation started promptly and progressed in a robust fashion for both treatments (Figure 1). In-house monitoring of residual sugar tested the control wine at 0.1 g/L on 9/6 (19 days post inoculation) while the stabulated wine was tested at 0.2 g/L glucose/fructose on 9/17 (23 days post inoculation).

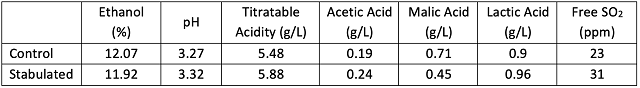

Table 3: Finished Wine Chemistry for two treatments of Rosé (ICV Labs 10/31/24)

Stabulation did not have a large impact on alcohol conversion or pH of the wine (Table 3). The stabulated wine has more evidence of malic acid depletion, shown in both lower malic acid concentration and higher pH. This may also be the cause of slightly higher acetic acid in this wine, though both wines had acetic acid concentration well below threshold values. After one month of aging, the wines had adequate free SO2 (>25 ppm) to prevent oxidation and protect thiols.

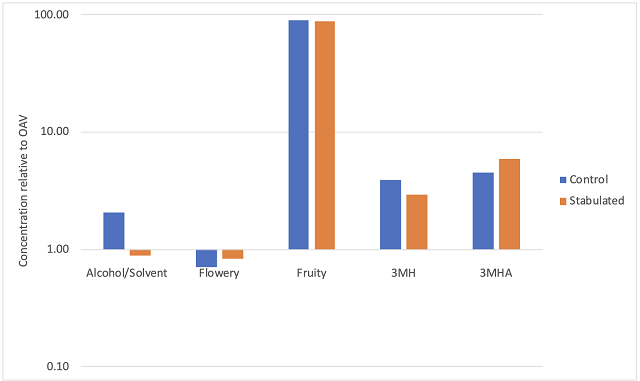

To assess aromatic differences between treatments, 14 esters and acetates were measured. These compounds were grouped into odor active vectors according to Ferreira et al (2022)6 and represented relative to their sensory thresholds, with an odor active value < 1 representing subthreshold levels (Figure 2). The control wine had above threshold concentration of aromas in the alcohol/solvent vector while the stabulated wine did not. Both wines had very high odor activity for the fruity vector. The control wine had higher concentration of 3MH, the varietal thiol associated with citrus such as lime, grapefruit and orange while the stabulated wine had higher concentration of 3MHA, a derivative of 3MH, which is associated with passionfruit, gooseberry and guava7. Both thiols are present in concentrations well above threshold in both wines, so it is unclear if these concentration differences would be evident in sensory analysis. Unfortunately, the wine was blended before formal sensory analysis could be done.

Figure 2: Esters, Acetates, and Thiols for two treatments of Rosé (NSEOS). Esters and acetates were grouped by aroma vector. All values are shown relative to threshold values. (OAV)

Logistical considerations

When considering if stabulation is something to add to your winemaking operations, there are several logistical considerations to keep in mind. Alec Bonnoront, the production manager at Michael Shaps Wineworks, mentioned the following:

- Stabulation ties up tank space during harvest. The delay in the onset of fermentation means that juice/wine stays in tank up to a week longer before it can be moved to storage. This can be a challenge if tank space is limiting.

- Stabulation adds a work order to mix tanks twice per day (or more).

- Juice that is held for stabulation should be in a topped tank to limit oxidation. It is often difficult to find the right sized tank when lots come in at variable sizes and many tanks are already filled during harvest.

- Bubbling CO2 in fully topped tanks requires care to avoid spillover.

Notes for stabulation success

Stabulation was a relatively new technique when WRE did its first experiments in 2016. After several rounds of experimentation, the following are a few lessons learned to help achieve higher aromatic expression through stabulation:

- Fruit intended for stabulation must be of good quality with little risk of microbial activity. If fermentation begins during stabulation, it will be very difficult to settle the juice prior to racking for fermentation.

- Use a yeast strain that is known to convert thiol precursors to thiols. Without this step, aromatics will remain hidden.

- Be careful to provide yeast with adequate rehydration and nitrogen nutrition (organic sources containing sterols) due to the reductive handling of the juice.

- If short duration stabulation is used, addition of Laffort Lafazyme Thiols enzyme will increase thiol extraction. Laffazyme THIOLS (Laffort) is a “pectolytic enzyme blend with secondary activity designed to proficiently increase yeast aromatic thiols revelation”. According to product information, this enzyme has been shown to have a statistically significant effect on 3MH and 3MHA thiols in the resulting wine and is designed to be used in conjunction with stabulation. Other companies likely have products with similar characteristics.

- Thiols are very sensitive to oxidation. During all phases of winemaking, protect the juice from oxygen with inert gas or dry ice to prevent the oxidation of thiols into odorless compounds. Add SO2 promptly after the completion of fermentation and keep free SO2 above 25 ppm. Glutathione-based products may also be helpful to retain thiols.

References

(1) Masson, G.; Schneider, R. Key Compounds of Provence Rosé Wine Flavor. Am J Enol Vitic. 2009, 60 (1), 116–122.

(2) Report | ARC by Laffort. https://arcbylaffort.com/stabulation-report/ (accessed 2018-12-13).

(3) Benkwitz, F.; Tominaga, T.; Kilmartin, P. A.; Lund, C.; Wohlers, M.; Nicolau, L. Identifying the Chemical Composition Related to the Distinct Aroma Characteristics of New Zealand Sauvignon Blanc Wines. American Journal of Enology and Viticulture 2012, 63 (1), 62–72.

(4) Jackson, R. S. Wine Science: Principles and Applications, 4 edition.; Academic Press: Amsterdam, 2014.

(5) Tominaga, T.; Baltenweck-Guyot, R.; Gachons, C. P. D.; Dubourdieu, D. Contribution of Volatile Thiols to the Aromas of White Wines Made From Several Vitis Vinifera Grape Varieties. Am J Enol Vitic. 2000, 51 (2), 178–181.

(6) Ferreira, V.; De La Fuente, A.; Sáenz-Navajas, M. P. Wine Aroma Vectors and Sensory Attributes. In Managing Wine Quality; Elsevier, 2022; pp 3–39.

(7) Coetzee, C.; Rafael, S.; CA; vines.com. Grape-Derived Fruity Volatile Thiols. Wines & Vines. http://www.winesandvines.com/features/197002 (accessed 2018-12-17).