Thiols are affected by all stages of winemaking

Thiols are affected by all stages of winemaking

Several WRE experiments in the 2018-2019 season were focused on increasing varietal thiols in aromatic white and rosé wines. These volatile compounds contribute to the varietal character of Virginia wines such as Sauvignon Blanc, Petit Manseng, and Riesling as well as varieties used to produce red and rosé wines. There are several steps in the winemaking process from vineyard to bottle that affect the production, protection and perception of thiols in the finished wine, and therefore several points of intervention for winemakers to consider if they want to increase the impact of these compounds.

“Volatile” or “varietal” thiols are a specific class of sulfur containing chemicals present in wine at very low concentrations. (They are measured in ng – that’s 1/1000th of a microgram, which is 1/1000th of a mg!) They were first identified in wine in late 1990’s as those “contributing toward typical aroma of Sauvignon Blanc” (Darriet and Tominaga 1995,Tominaga et al 1996) and, in recent years, have come to be seen as essential to the varietal character of this grape (Benkwitz et al 2012). These are not to be confused with other sulfur-based compounds that contribute to reductive odors and flavors such as cooked leaks, asparagus, and onions. (Another word for thiol is mercaptan. There are several kinds.)

Very high levels of varietal thiols characterize New Zealand Sauvignon Blanc and drive this style of wine (Coetzee 2018 Wines and Vines). Levels in other regions are lower, but are still above the threshold of perception. Varietal thiols have since been reported above the threshold of perception in a number of different varieties including: Gewürtzaminer, Muscat, Riesling, Pinot Gris, Colombard, Chenin blanc, Sauvignon blanc, Sémillon, Petit Manseng, Chardonnay, Merlot, Cabernet Sauvignon, Cabernet Franc, Grenache, Syrah, Cinsault, Mourvèdre, Pinot Noir, and Malbec (Tominaga et al 2000, SARCO lab, Bouchilloux et al 1998). Aromatic analysis of Provencal rosé by Masson and Schneider (2009) identified four molecules responsible for the fruity and amylic notes of these wines; two are thiols.

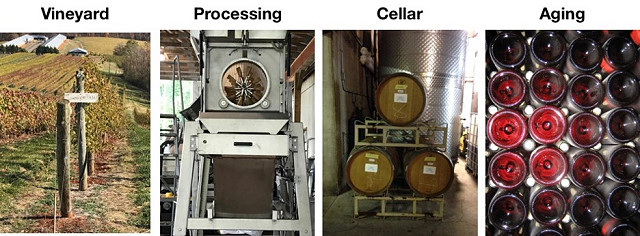

The three varietal thiols that are primarily responsible for the tropical fruity aromas of these wines are shown in Table 1. Each has a very low threshold of detection and can have different perception depending on its concentration. At lower concentrations, 4MMP smells like boxwood and broom, but at high concentrations it smells like cat urine. A3MH is “fruity” at lower concentrations and “sweaty” at high concentrations. In addition to fruit aromas, thiols can also contribute “green” odors such as green pepper and stalky attributes and can enhance the perception of methoxypyrazine (which is also present in Sauvignon Blanc) (Coetzee 2018). Bruce Zoecklein recalled being puzzled at the reduction in perception of methoxypyrazine when first testing microoxygenation, since the measured levels of methoxypyrazine were not decreasing. Eventually the team came to realize that microoxygenation was oxidizing the thiols, which were amplifying the perception of pyrazine (Zoecklein, personal communication).

Concentrations of thiols in aromatic wines can vary widely. For example, 3MH levels have been reported from 29-20,000 ng/L (Coetzee 2018). However the effect of minor differences in thiols concentration has not yet been reported in the literature. One study reported that a difference in 3MH between 0 and 875 ng/L did not greatly affect the aroma of a Sauvignon Blanc (Coetzee 2018), indicating that though these molecules have low sensory thresholds, discrimination among levels may be much less sensitive.

Since the discovery of varietal thiols, many studies have been conducted examining the effect of vineyard and winery practices on their production.

In the vineyard, several factors affect production of thiol precursors.

Precursors

Varietal thiols are not present in volatile forms in grapes or juice, but rather as precursors bound to other compounds that must be released by yeast enzymes during fermentation in order to be aromatic.

Several precursor molecules have been identified as potentially important to the production of varietal thiols in wine. Prime candidates include a cysteine conjugate of 3MH, and a glutathione conjugate of 3MH that are present in varying concentrations in must and are resistant to oxidation until cleavage. This means that they are relatively protected at juice stage and only vulnerable after fermentation.

Other candidate precursors include (E)-2-hexanal and other C6 compounds. These are released as anti-microbial compounds when the plant cells are damaged and are toxic to Saccharomyces. During fermentation, the yeast convert the toxic compounds into less toxic compounds by combining them with glutathione (which is present in grape must) to form Glut-3MH. Glut-3MH is a thiol precursor that can then be converted to varietal thiols. C6 compounds can only become thiol precursors if a sulfur containing compound is available, leading to several ideas about way to increase sulfur early in fermentation, including bubbling H2S! (Coetzee 2018).

Even if precursors are present in high concentrations, that is not a guarantee of a highly aromatic wine. When testing 55 different juice/wine pairs Pinu et al (2012) found no correlation between the precursors in juice and the final thiols in wine. Conversion yield of any of these compounds is very poor (0.1% to 12%). Though much remains to be known about the relationship between thiol precursors and final thiol concentrations, several practical steps in winemaking have been shown to be important in thiol production in wines.

Extraction

The first step is to extract as many thiol precursors as possible. Sixty percent of Cys-3MH is localized in grape skins while Cys-4MMP is present in both skin and pulp. Prolonged skin contact coupled with higher fermentation temperature was shown to increase 3MH in Merlot and Cab Sauv (Roland et al 2011). In the same study, harder pressing (2 atm) was shown to extract higher levels of 3MH precursors from Sauvignon Blanc and Melon B grapes, however care must be taken as higher extraction of phenols with high pressure could lead to oxidation later. Skin contact and extraction enzymes are also thought to increase extraction of thiol precursors (Chauffour webinar).

Stabulation of juice lees and enzyme treatment are also thought to increase the extraction of thiol precursors from juice pulp, but with mixed results. The Applied Research Cooperative of Laffort tested the effects of stabulation and enzyme treatment through a multi-site trial including 21 different locations in 2016, including two trials submitted by the WRE. Here only 12 of the 21 wines showed a significant difference between trials and controls in a triangle test, and preferences were split between stabulated and non-stabulated wines. ENose analysis of a subset of these wines done by Bruce Zoecklein showed significant differences while analysis of thiol molecules showed mixed results; of 8 trial wines tested, 5 showed increase in thiols with stabulation, 1 showed a decrease, and 2 had no significant difference between stabulated and non-stabulated wine. Treatment with thiolase enzyme had a larger effect on thiols than stabulation in 3 of 4 wines tested (Laffort, n.d)

Additions

Addition of specialized nutrients may also increase thiol production. Yeast nutrients are routinely added to fermenting must to augment nitrogen for yeast metabolism. Several enological companies have now begun to offer yeast nutrients specially formulated to enhance aromatics of the wine, including formulations to increase thiols. Stimula Sauv Blanc from Scott Labs is formulated to “optimize the uptake of 3MH and 4MMP precursors” as well as stimulate their conversion to thiols in the yeast. AEB sells Fermoplus Tropical with similar description. Three WRE trials were done this year using these products.

In addition to nutrients, Larcher et al (2015) showed the addition of grape tannin containing a significant concentration of S-glutathionylated (GSH-3MH) and S-cysteinylated (Cys-3MH) to fermentation of Meuller-Thurgau and Sauvignon Blanc musts produced wines with higher levels of 3MH and 3MHA. Informal sensory analysis in this study found that the Sauvignon wines produced with the tannin addition were often richer with increased ‘“fruity/green”’ notes, as would be expected with higher thiol concentrations.

Fermentation factors

As mentioned above, yeast are needed to convert thiol precursors to aromatic molecules through action of beta-lyase endopeptidase enzymes. Another enzymes, acetyl-transferase, is needed to convert 3MH to 3MHA. In a study of Bordeaux Sauvignon Blanc, Dubourdieu et al (2006) found variation in the conversion ability between yeast strains. The genetic basis of precursor conversion has been described (Howell et al 2005, Thibon et al 2009) and a family of genes has been identified as responsible. There can be up to 25-fold difference in expression of thiols from one yeast strain to another (BZ, pers comm). Enological companies now market specific yeast strains as “thiol producing”, because they have high number of these genes. Expression of these genes can be turned off by high levels of nitrogen in the juice (Thibon et al 2009), so addition of DAP can decrease thiol release.

Several studies show that fermentation temperature affects thiol release, but guidelines are highly variable (Roland et al 2011). Masneuf-Poumarede et al (2006) tested the effect of temperature and yeast strain on thiol production in Sauvignon Blanc and found temperature had an effect regardless of yeast strain, with higher levels of thiols produced in fermentations conducted at 68F (20 C) compared to 55 F (13 C). In their Sauvignon Blanc style guide, Scottlabs recommends an increase in temperature from 59F (15 C)-65F (18 C) degrees for mineral driven Sauvignon Blanc to 65 (18 C) -72 F (22 C) degrees for tropical Sauv Blanc.

Protection

Once thiols have been produced through fermentation, they must be protected from oxidation because once oxidized, thiols lose their aroma. Thiols are oxidized as part of the following pathway:

Since thiols are present in such small amounts, a small amount of oxidation can cause a big effect on aroma. However, understanding these steps give us several targets for intervention to protect thiols from oxidation:

Aging

Even when bottled, 3MH and 3MHA continue to evolve. Based on reports that the intense tropical fruit aromas of New Zealand Sauv Blanc diminished rapidly in the bottle, Herbst-Johnstone et al (2011) monitored the evolution of 3MH and 3MHA as well as levels of glutathione and SO2 in bottled wine stored in the dark at 15 degrees C for 7 months. They found 3MHA (passionfruit, guava) was the least stable, declining steadily. 3MH decreased only slightly in the first 3 months, then increased in the last 4 months. The authors hypothesize 3MHA is hydrolyzing back to 3MH during this time. Glutathione concentrations also declined to the point they were no longer protecting the thiols after the first year while SO2 remained stable.

Production of wine with high tropical fruit aromas requires care in all steps of the winemaking from the vineyard to the bottle. The molecules responsible for this style of wine are present in very small concentrations, have low perception thresholds, and are vulnerable to loss due to oxidation. Though the mechanism of their production is not yet fully understood, some tools are available for the vigneron to make informed choices to produce the style of choice:

References

Four experiments were done in the 2018-2019 season exploring the optimization of thiols in aromatic wines

Thiols have become a defining characteristic of aromatic Sauvignon Blanc wines. Early defoliation in the fruit zone has been shown to increase thiol production in South African Sauvignon Blanc (Šuklje et al 2104). In this study, leaves were removed from the east side of the fruit zone immediately after fruit set. Control rows had no leaf pulling. Resulting wines showed no differences in major chemistry, however wines with leaves pulled had lower concentration of thiols. Sensory analysis of resulting wines showed higher thiol intensity in control wines, with these wines also scoring significantly higher for aromatic intensity and acidity.

Thiols have been shown to be important contributors to varietal character in Sauvignon Blanc (Tominga et al 1998). Šuklje et al (2014) showed that defoliation of the fruit zone just after fruit set (when berries were peppercorn size) led to wines with higher thiols and lower methoxypyrazine than controls. In the same study, sensory analysis by a trained panel showed that defoliation was associated with fruity descriptors such as tropical, passionfruit, grapefruit, and pineapple while the shaded control was associated with “green” descriptors such as cooked beans/peas, acidity and green pepper. Sukje et al (2014) undertook their work in the Overberg region of South Africa. This study aims to determine if these results are transferable to Oregon Sauvignon Blanc.

Immediately following fruit set, 100 % of leaves were pulled from the morning (east) side of the fruit zone in every other row of 4 identical rows of Sauvignon Blanc (Musque Clone 101-14 rootstock). Two rows had zero leaf pull throughout, though these rows were monitored for signs of disease or mildew pressure, neither of which presented during the growing season. The two lots were picked separately but identically on the same day into 4 x 16A non slotted macrobins (2 trial, 2 control). Immediately following harvest each bin was treated with 10mg/L SO2 and cooled overnight at 6°C. The following day each lot was pressed separately but identically with the addition of 37ppm SO2 and transferred to separate 500L stainless steel tanks. Juice was fined with 10 g/hL NBI (chitosan) and 12.9 g/hL bentonite, then cold settled (6°C) for 48 hours, after which they were racked into another set of 500L stainless steel tanks. After 48 hours the temperature increased to 12°C and both tanks were inoculated with 20g/hL Excellence FTH yeast (Lamothe Abeit) rehydrated in 30 g/hL Go Ferm. After 36 hours, signs of fermentation were present and YAN was increased by 100mg N/L using DAP. Both lots were fermented dry and 8g/hL Extralyse was added. Eleven days following Extralyse, 35ppm SO2 was added and both tanks were moved to storage at 12°C. Both tanks were stored with identical head space and are layered with argon once a week until sampling for analysis.

Wines were tasted at sensory session conducted in January 2019 by 27 winemakers and other production staff. No formal training was conducted, however informal standards of “bell pepper”, “passionfruit”, “grapefruit” and “boxwood” were provided. All samples were presented in clear glasses with random three-digit numbers. Two glasses were presented, each with 2 ounces of wine. Panelists were asked to identify which of the wines had more perceptible thiols (a paired difference test), then to evaluate each wine for aromatic intensity, green aromas, fruit intensity, and acidity. To prevent the dumping effect, panelists were also given two opportunities to write their own descriptors, in conjunction with the triangle test and in a comment box at the bottom of the scoring sheet.

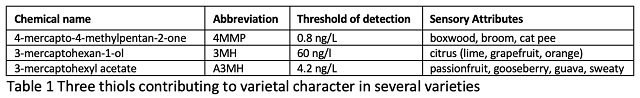

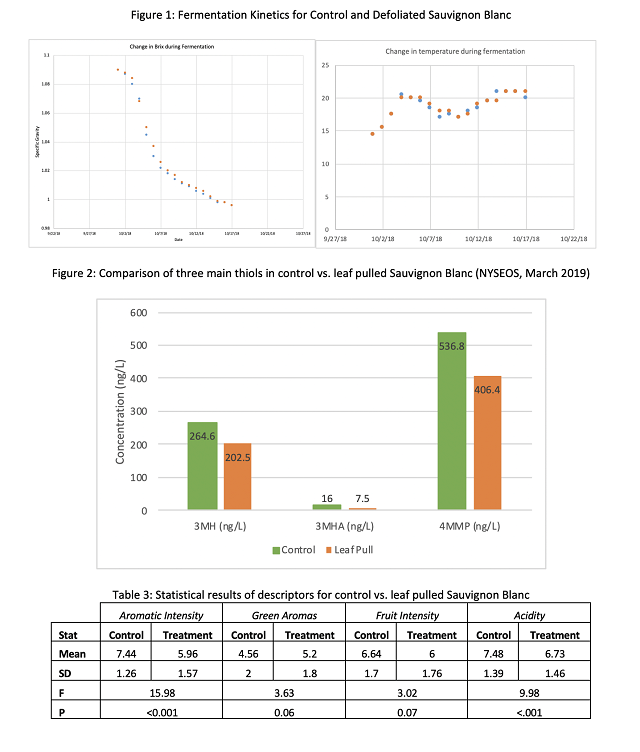

Juice chemistry is shown in Table 1 and finished wine chemistry is shown in Table 2. The difference in Brix found in the fruit (21.2 in control vs. 21.7 in treated) translated to a difference in alcohol in the finished wine (13.1 vs. 13.5%). All other juice and wine chemistry measurements are very similar. Fermentation progressed at the same rate in both tanks with little difference in temperature (Figure 1).

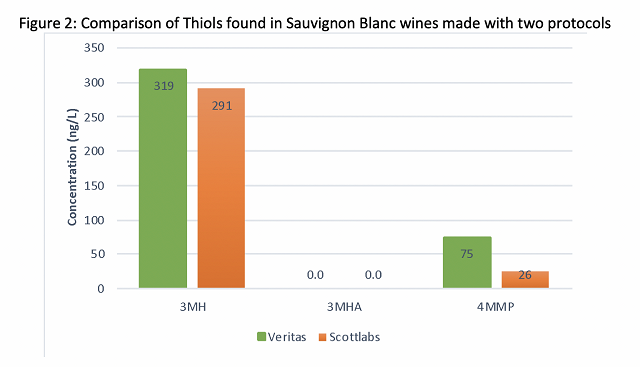

Concentration of three main thiol compounds, 3MH, 3MHA and 4MMP were measured by NYSEOS in March of 2019 (Figure 2). All three compounds were found above the sensory threshold of detection in both treatments. Levels of all three compounds were higher in the control than the leaf pull treatment. In a paired difference test, 22 of 27 respondents chose the control wine as having higher perceptible thiols with comments that both wines had intense thiols, citing citrus, passionfruit and grapefruit as descriptors that helped make their choice. This is a significant difference (Z=2.46, p=0.0069). Table 3 lists results of repeated measures ANOVA for each descriptor. The control wine scored higher for both aromatic intensity and acidity, though the means for these descriptors were very similar, indicating a consistent but small difference.

In this study, partial defoliation led to a decrease in measurable thiol concentration as well as perception to thiol intensity. This is contrary to the expected findings, as outlined by Šuklje et al (2014).

References

Thiols have become a defining characteristic of aromatic Sauvignon Blanc wines. Enological companies have developed specialized nutrients to increase thiol production during fermentation. In this study, fermentation using Stimula Sauv Blanc, a yeast nutrient specialized for thiol production is compared to fermentation using Fermaid O, a non-specialized yeast nutrient. Resulting wines had very similar general chemistry and thiol content. Triangle difference testing concluded the wines were different, however scores for thiol intensity were not significantly different between wines. Some fruity and floral esters were higher in the wine produced using Stimula Sauv Blanc.

Grassy, bell pepper, box tree, broom, grapefruit and passionfruit are all descriptors used for the varietal character of Sauvignon Blanc. The chemicals that are responsible for this varietal character, 4MMP, 3MH and 3MHA have been described by Tominaga et al (1998). These chemicals are not present in grape juice, but rather precursors are transformed during the course of fermentation by yeast cells (Pinu et al 2012). The production of thiols requires that precursors are available in the fermentation and can be transported into yeast cells. Yeast cells must also have the cellular machinery to perform the transformation. As the base of knowledge surrounding production of aromatic thiols in Sauvignon Blanc (and other aromatic wines) has grown, so has interest in the mechanisms that convert precursors into aromatic compounds and how these can be used to maximize expression of thiols in the wine.

Yeast nutrients are routinely added to fermenting must to augment nitrogen for yeast metabolism. Several enological companies now offer yeast nutrients specially formulated to enhance aromatics of the wine by supplying components to optimize yeast metabolism. Stimula Sauv Blanc from Scott Labs is formulated to “optimize the uptake of 3MH and 4MMP precursors” as well as “stimulate their conversion to thiols in the yeast”. Product information includes the recommendation to add these nutrients early in fermentation to avoid catabolite repression and increase transporter efficiency. This study compares thiol production and perception in Sauvignon Blanc treated with Stimula Sauv Blanc compared to Fermaid O, the standard nutrient used by the winery.

Grapes were harvested and processed according to the standard protocol of the winery with addition of nutrient the only difference between lots. One lot received 20 g/hL Fermaid O (8 ppm Nitrogen) while the other lot received 30 g/hL Stimula Sauv Blanc (12 ppm Nitrogen), as per manufacturer’s instructions. Nutrients were added one day after inoculation. All other aspects of winemaking remained the same. Briefly, fruit was lightly crushed without destemming and pressed to tank. Juice was cold settled and fined with Claril SP and Stab Micro M with racking in between. Fined juice was then racked to two separate but identical concrete eggs for fermentation. Juice was inoculated with 15 g/hL Zymaflore X5 (a thiol-releasing yeast) rehydrated in 20 g/hL Superstart Blanc. Prior to the onset of fermentation, 1.25 g/L tartaric acid, 0.4 g/L malic acid and 15 g/L sugar were added. Fermentations took place at cellar temperature (without cooling) and were monitored for brix and temperature daily. At the completion of fermentation 50 ppm SO2 was added. Wine was aged on lees with stirring with SO2 and pH monitoring.

Wines were tasted at a sensory session conducted in January 2019 by 30 winemakers and other production staff. No formal training was conducted, however informal standards of “bell pepper”, “passionfruit”, “grapefruit” and “boxwood” were provided. All samples were presented in clear glasses with random three-digit numbers. Three glasses were presented, each with 2 ounces of wine. Panelists were asked to identify which of the three wines was different (a triangle difference test), then to evaluate each wine for thiol intensity. To prevent the dumping effect, panelists were also given two opportunities to write their own descriptors, in conjunction with the triangle test and in a comment box at the bottom of the scoring sheet.

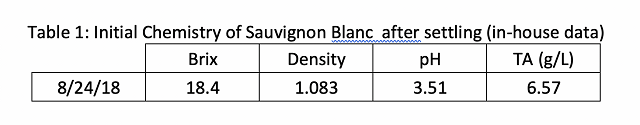

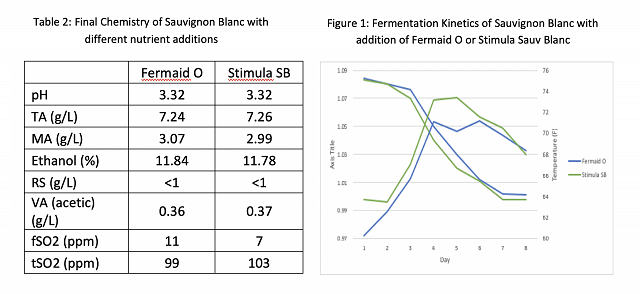

Table 1 reports the initial juice chemistry after settling. Wine chemistry after fermentation was the same for both lots (Table 2). Fermentation kinetics were very similar, though the temperature in the Stimula Sauv Blanc treatment was several degrees warmer during days 4 and 5 (Figure 1).

The concentration of three main thiol compounds, 3MH, 3MHA and 4MMP were measured by NYSEOS in March of 2019 (Figure 2). Two of the three (3MH and 4MMP) were found above the sensory threshold of detection in both treatments, and in equal amounts between treatments. 3MHA was not detected in these samples. In a triangle test 18 out of 30 respondents were able to distinguish which wine was different. This is a significant difference (Z=3.11, p<0.001). There were no consistent patterns in descriptors given for the difference perceived. Fermaid O had a mean thiol intensity of 5.24 (SD=1.75) and Stimula Sauv Blanc had a mean thiol intensity of 4.65 (SD=1.54). These scores were not significantly different.

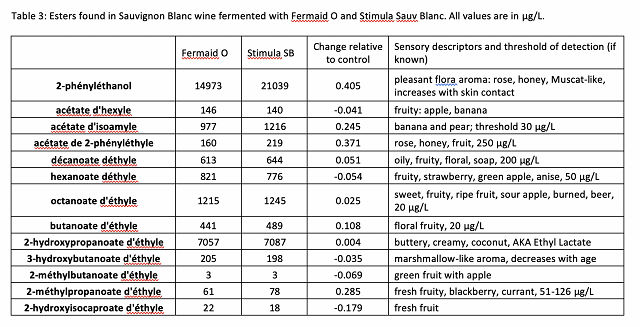

Esters were also analyzed by NSEOS in March of 2019 (Table 3). The wine fermented with Stimula Sauv Blanc had higher levels of esters in general, with notably higher amounts of esters contributing to pleasant floral aromas (2-phenylethanol).

Wines produced from fermentation with Fermaid O and Stimula Sauv Blanc were different, however there were no large differences in thiol intensity or concentration. Wines produced with Stimula Sauv Blanc had higher levels of some fruity and floral esters which may have contributed to this difference.

References

Pinu, F. R., S. Jouanneau, L. Nicolau, R. C. Gardner, and S. G. Villas-Boas. (2012) “Concentrations of the Volatile Thiol 3-Mercaptohexanol in Sauvignon Blanc Wines: No Correlation with Juice Precursors.” American Journal of Enology and Viticulture 63, 3: 407–12.

Tominaga, T., A. Furrer, R. Henry, and D. Dubourdieu. (1998). Identification of new volatile thiols in the aroma of Vitis vinifera L. var. Sauvignon blanc wines. Flav. Frag. J. 13:159-162.

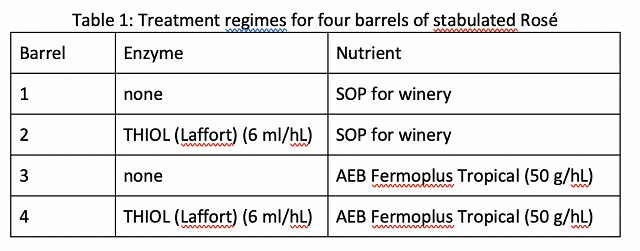

Based on results of previous studies of stabulation focusing on thiol production in rosé and Sauvignon Blanc, Cardinal Point has decided to adopt stabulation in the production of its Cabernet Franc based rosé. To develop the protocol, several elements of a thiol-producing approach were tested individually and in concert including use of THIOLS (Laffort) enzyme and Fermoplus Tropical (AEB) nutrient. All treatments in the trial received stabulation, with addition of enzyme and nutrient both separately and together. Finished wine chemistry was the same for all treatments. In a ranking test for aromatic intensity, the wine treated with both enzyme and specialized nutrient ranked significantly higher than the other treatments, however there were no significant differences among the wines for descriptors of thiol intensity or green/herbal quality.

The character of Provençal style rosé is partially determined by the presence of thiols in the wine (Masson and Schneider 2009). SARCO lab has previously reported thiols (3MH and 3MHA) in rosé wines produced from a number of grapes including Merlot, Cabernet Franc, and Cabernet Sauvignon, irrespective of geographic origin. There are many steps in the production of wine that affects thiol expression, including interventions in the vineyard as well as the winery. Stabulation and enzyme treatment are both interventions designed to increase the extraction of thiol precursors from the juice pulp. Specialized yeast nutrients are also available to enhance aromatics of the wine by supplying components to optimize yeast metabolism.

The Applied Research Cooperative of Laffort tested the effects of stabulation and enzyme at 21 different winery locations in 2016, including two trials submitted by the WRE. In these trials, 12 of the 21 wines showed a significant difference in a triangle test, though preferences were split between stabulated and non-stabulated wines. ENose analysis showed significant differences between stabulated and non-stabulated wines, indicating the treatment did have an effect. Thiol analysis showed mixed results; of 8 trial wines tested, 5 showed increase in thiols with stabulation, 1 showed a decrease, and 2 had no significant difference between stabulated and non-stabulated wine. Treatment with thiolase enzyme had a larger effect on thiols than stabulation in 3 of 4 wines tested (Laffort, n.d.). Addition of specialized nutrition to this protocol could further enhance aromatic expression.

Based on results of previous studies on stabulation focusing on thiol production in rosé and Sauvignon Blanc, Cardinal Point has decided to adopt stabulation in the production of its Cabernet Franc based rosé. To develop the protocol, several elements of a thiol-producing approach were tested individually and in concert. Laffazyme THIOLS (Laffort) is a “pectolytic enzyme blend with secondary activity designed to proficiently increase yeast aromatic thiols revelation”. According to product information, this enzyme has been shown to have a statistically significant effect on 3MH and 3MHA thiols in the resulting wine and is designed to be used in conjunction with stabulation. Fermoplus Tropical (AEB) is a yeast autolysate nutrient that is formulated to increase amino acid uptake and increase production of an “aromatic tropical profile”.

Fruit was crushed and destemmed into TBins, layering pressing enzyme with Fermotan (AEB), SO2and CO2 to prevent oxidation. After maceration, fruit was pressed to tank with CO2 in the press and the pan. After pressing, the tank was cooled to 32°F for 4 days of stabulation with twice daily anaerobic stirring followed by blanketing with CO2. To accomplish this, a CO2 regulator was set to very slowly trickle gas into the must continuously. The tank was mixed twice per day by turning up the gas pressure to a “boil”, then turning on the mixer for one minute. The tank was then allowed to warm to 50°F prior to racking off stabulation lees. After racking, juice was transferred to 4 experimental barrels, each to be treated according to the regime found in Table 1.

Each barrel was inoculated with X-5 (a thiol-producing yeast) at 20 g/hL and chaptalized at a rate of 16 g/L (for a total of 3600 grams per barrel) prior to the onset of fermentation. A juice panel showed YAN = 104. Nutrient additions included 12.5 g/hL Fermaid K and 12.5 g/hL DAP added at the beginning of fermentation and again at at ⅓ brix depletion. For barrels 3 and 4, Fermaid K was replaced by an equal amount of Fermoplus Tropical. DAP addition remained the same for all barrels. The overall nitrogen impact of Fermaid K is 25 ppm whereas the overall nitrogen impact of Fermoplus Tropical is 27 ppm. In addition, 30 g/hL Polymust Rosé was added to all barrels two days after inoculation for protection against oxidation. All barrels underwent fermentation in the same ambient temperature environment. Fermentations were monitored daily for brix and temperature. Upon completion of fermentation, 25 ppm SO2 was added, barrels were topped and wine was aged on lees. SO2 was adjusted to a common target as needed.

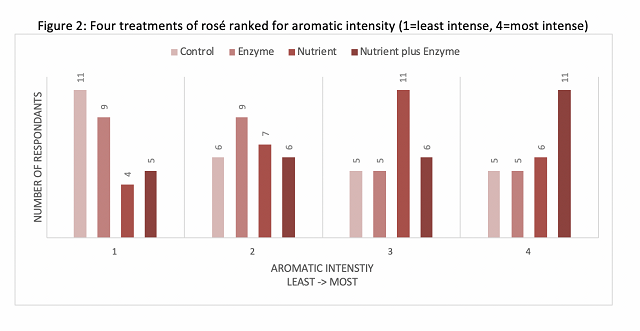

Wines were tasted at sensory session conducted in January 2019 by 28 winemakers and other production staff. No formal training was conducted, however informal standards of “bell pepper”, “passionfruit”, “grapefruit” and “boxwood” were provided. All samples were presented in clear glasses with random three-digit numbers. Four glasses were presented, each with 2 ounces of wine. Panelists were asked to rank the wines in order of aromatic intensity, then to evaluate each wine for thiol intensity and green/herbal character. To prevent the dumping effect, panelists were also given two opportunities to write their own descriptors, in conjunction with the ranking test and in a comment box at the bottom of the scoring sheet.

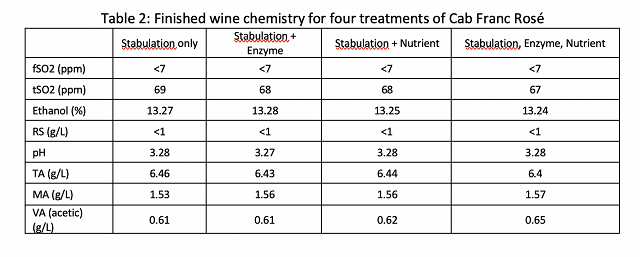

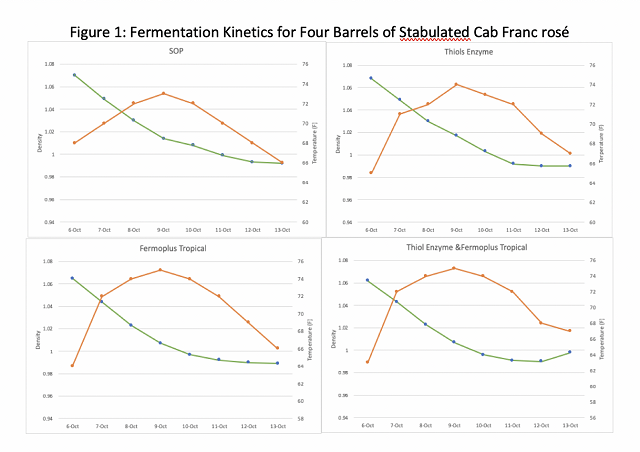

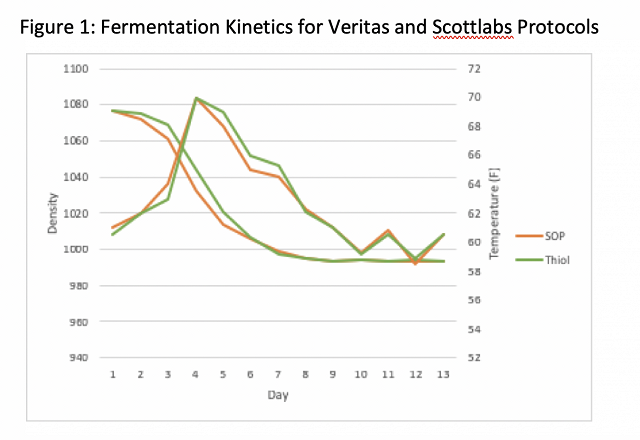

Treatments caused no differences in finished wine chemistry (Table 2). Fermentation kinetics can be seen in Figure 1. Barrels with Thermoplus Tropical had slightly higher maximum temperature (75°F vs. 74°F and 73°F for the other two barrels). The stabulation only barrel had slightly slower fermentation, reaching dryness two days after the other three barrels. This is consistent with its slightly cooler temperature.

In the ranking test, participants were significantly more likely to choose the wine treated with stabulation, enzyme and nutrient as the most aromatically intense (Friedmans Test: Q=10, P=0.03) (Figure 2). There were no significant differences in scores for thiol intensity or green/herbal quality among the wines.

Addition of THIOLS enzyme for release of aromatic components coupled with Fermoplus Tropical specialized yeast nutrient increased aromatic intensity in stabulated rosé.

References

Masson, G., and R. Schneider. (2009) “Key Compounds of Provence Rosé Wine Flavor.” American Journal of Enology and Viticulture 60(1):116–22.

“Report | ARC by Laffort.” Accessed December 13, 2018. https://arcbylaffort.com/stabulation-report/.

Thiols have become a defining characteristic of aromatic Sauvignon Blanc wines. Enological companies have developed specialized products to increase thiol production during fermentation and protection during aging. In this study, the standard protocol used at Veritas for production of Sauvignon Blanc is compared to the protocol recommended by Scottlabs. General wine chemistry was the same for both treatments. Wines were distinguished as different in a triangle test, with the Veritas protocol scoring higher in thiol intensity. Concentration of thiols and select esters were higher in the Veritas protocol wine.

Grassy, bell pepper, box tree, broom, grapefruit and passionfruit are all descriptors used for the varietal character of Sauvignon Blanc. The chemicals that are responsible for this varietal character, 4MMP, 3MH and 3MHA have been described by Tominaga et al (1998). These chemicals are not present in grape juice, but rather precursors are transformed during the course of fermentation by yeast cells (Pinu et al 2012). The production of thiols requires that precursors are available in the fermentation and can be transported into yeast cells. Yeast cells must also have the cellular machinery to perform the transformation. As the base of knowledge surrounding production of aromatic thiols in Sauvignon Blanc (and other aromatic wines) has grown, so has interest in the mechanisms that convert precursors into aromatic compounds and how these can be used to maximize expression of thiols in the wine.

There are many steps in the course of production that affect thiol expression in the finished wine, including interventions in the vineyard as well as the winery. Scottlabs “Tropical (Thiol) Profile” protocol takes advantage of several of these steps to maximize expression of thiols and prevent them from oxidation, including targeting a higher level of turbidity after racking, inoculating with a thiol-producing strain of yeast (such as QA23 or Alchemy II), fermenting at a relatively warm temperature, use of a specialized yeast nutrient (Stimula Sauv Blanc) and addition of a glutathione-rich antioxidant.

The standard protocol for Sauvignon Blanc production at Veritas Vineyard and Winery already employs some of these principles. This experiment compares the wine produced by the standard protocol for the winery with that produced when multiple aspects of the Scottlabs protocol were employed to determine if additional steps should be included in the future. This experiment is a comparison of the protocol as a whole, with several factors differing between lots.

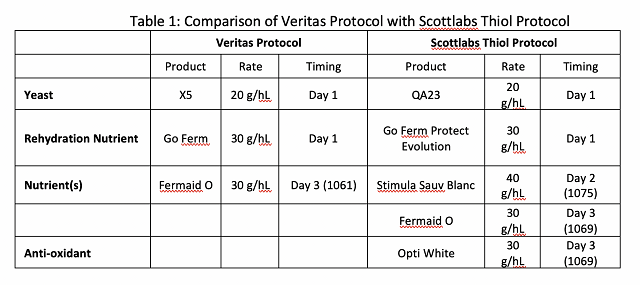

Fruit was crushed and destemmed into T-bins with an addition of 70ppm SO2. Bins were stored in a refrigerated environment overnight, then pressed with the press fraction cut at cycle 20. Juice was cold settled with the addition of 1.6 ml/hL Cinn Free for one day prior to racking to two stainless steel barrels. This was a small portion of a larger lot, so care was taken to avoid any bottom lees while racking. Both barrels were inoculated with 20 g/hL yeast rehydrated in 30 g/hL rehydration nutrient, and chaptalized with 0.5 g/L sugar the day after fermentation began. Table 1 shows the remaining additions to these barrels. Fermentations were monitored daily. At the completion of fermentation 45ppm SO2 was added.

Wines were tasted at sensory session conducted in January 2019 by 30 winemakers and other production staff. No formal training was conducted, however informal standards of “bell pepper”, “passionfruit”, “grapefruit” and “boxwood” were provided. All samples were presented in clear glasses with random three-digit numbers. Three glasses were presented, each with 2 ounces of wine. Panelists were asked to identify which of the three wines was different (a triangle difference test), then to evaluate each wine for thiol intensity. To prevent the dumping effect, panelists were also given two opportunities to write their own descriptors, in conjunction with the triangle test and in a comment box at the bottom of the scoring sheet.

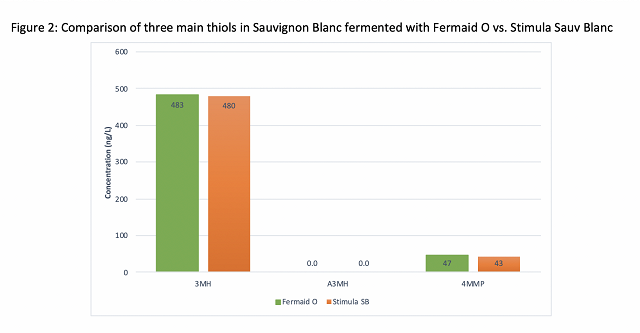

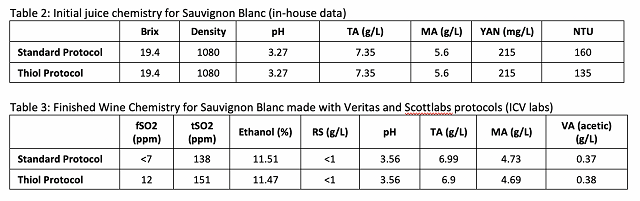

There was no difference in initial juice chemistry (Table 2). Fermentation kinetics (Figure 1) and finished wine chemistry (Table 3) were also very similar.

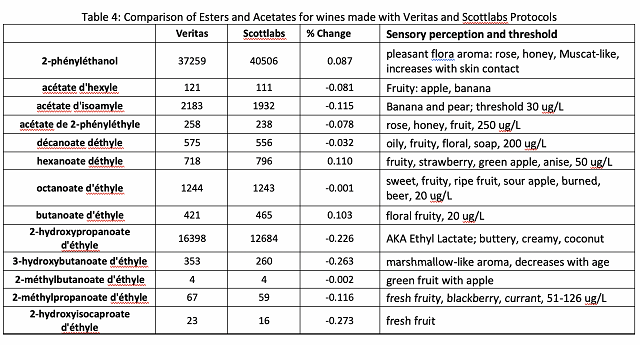

Concentration of three main thiol compounds, 3MH, 3MHA and 4MMP were measured by NYSEOS in March of 2019 (Figure 2). Two of the three (3MH and 4MMP) were found above the sensory threshold of detection in both treatments while 3MHA was not detected in these samples. The Veritas protocol had slightly higher 3MH but three times as much 4MMP. In a triangle test 25 out of 30 respondents were able to distinguish which wine was different. This is a significant difference (Z=5.62, p<0.001). The wine made with the Veritas protocol had a mean thiol intensity of 6.08 (SD=1.78) and Stimula Sauv Blanc had a mean thiol intensity of 4.92 (SD=1.42). These were significantly different (F=8.42, P=0.01). Esters were also analyzed by NSEOS in March of 2019 (Table 4). The largest proportional differences are lower levels of compounds lending fresh fruit and buttery/creamy/marshmallow sensations.

Wine made from the Scottlabs protocol was different from wine made from the Veritas protocol. The Veritas protocol wine had higher levels of 3MH and 4MMP and scored higher for thiol intensity. This wine also had slightly higher levels of select esters.

References

Pinu, F. R., S. Jouanneau, L. Nicolau, R. C. Gardner, and S. G. Villas-Boas. (2012) “Concentrations of the Volatile Thiol 3-Mercaptohexanol in Sauvignon Blanc Wines: No Correlation with Juice Precursors.” American Journal of Enology and Viticulture 63, 3: 407–12.

Tominaga, T., A. Furrer, R. Henry, and D. Dubourdieu. (1998). Identification of new volatile thiols in the aroma of Vitis vinifera L. var. Sauvignon blanc wines. Flav. Frag. J. 13:159-162.