Preventing malolactic fermentation during aging in sparkling wine base (2021)

Matthieu Finot

King Family Vineyards

Summary

Sparkling wine base is one of several examples of low SO2 white wines for which malolactic fermentation is not desired. Chitosan is one alternative to SO2 that may help prevent malolactic fermentation in barrel fermented white wines. In this experiment, two different approaches to chitosan treatment were explored as a way of preventing malolactic fermentation in sparkling wine base: addition at the beginning of fermentation, and addition at the end of fermentation. The experiment was replicated in two different lots of fruit with two control barrels and three of each treatment barrel per lot. Neither of the chitosan treatments was sufficient to consistently prevent malolactic fermentation. Wines that underwent malolactic fermentation consistently had higher pH and acetic acid values. Wines were significantly different in triangle testing with wines that underwent malolactic fermentation receiving lower descriptive scores for perception of acidity and higher descriptive scores for lactic character and volume/body.

Introduction

In 2020, Matthieu Finot experimented with using malolactic fermentation in sparkling wine base to moderate the high malic acids of the vintage. During the 2020 experiment, some control (non-ML) barrels still went through malolactic fermentation despite addition of 23 ppm SO2 at crush, 3 g/hL of Stab Micro M and 3 g/hL SO2 at the completion of alcoholic fermentation. Malolactic fermentation predictably led to a change in sensory profile from highly acidic to creamy/buttery as well as increases in volatile acidity and pH. Sparkling wine base is not the only example of white wines for which malolactic fermentation is not desired. With increasing emphasis on lowering SO2 rates, what other avenues are available to prevent unwanted malolactic fermentation?

Several conditions can inhibit or prevent malolactic fermentation1 including:

- Cold temperature (below 10°C)

- Early and frequent racking

- Early clarification (before and after fermentation)

- Acidification if pH is high

- Minimal maceration time

- Avoidance of sur lies maturation

- Maintaining total SO2 above 50 ppm

- Use of lysozyme (more effective at high pH)

- Chitosan fining

Several of these factors, including cold temperature, low pH, direct press, are already in place for sparkling wine production at King Family, while others, such as racking off lees and higher SO2 rates, are not well applied to sparkling wine base.

Another possible approach is to treat the wine with chitosan. Chitosan is a naturally occurring molecule that can also be produced by the de-acetylation of chitin using NaOH or chitinase enzymes2. Chitin is the second-most common polymer found in nature (after cellulose), making up the cell walls of fungi and shells of crustaceans and is thus readily available as a renewable resource3. Chitosan has been used worldwide at nearly every stage of wine production including vineyard applications, on grapes during transport and storage, at crush, after fermentation and during aging of wine4. During fermentation and aging, chitosan binds to the cell walls of gram negative bacteria (such as Oenococcus and Lactobacillus), causing possible disruption of their cell membranes, ATP leakage, and sedimentation5,6. Manufacturer’s recommendations include using chitosan for prevention of malolactic fermentation. In 2021, the maximum allowable rate of chitosan addition was raised from 10 grams/100 liters to 500 grams/100 liters, allowing for more freedom in use of this antimicrobial agent.

In this experiment, two different approaches to chitosan treatment were explored as a way of preventing malolactic fermentation in sparkling wine base:

-

Treatment 1: 15 g/hL Stab Micro M was added at the beginning of fermentation to decrease the overall population of Oenocccus (as per recommendation of product representative)

-

Treatment 2: 0 g/hL Stab Micro M at the beginning of fermentation with 7 g/hL at the completion of fermentation. Wine was then aged on lees without racking off chitosan.

Both treatments were compared to a control that received no chitosan treatment.

Methods

This experiment was replicated in two separate lots of fruit. For each lot (KFV 2 and CO3), the standard protocol of the winery was followed with the sole exception of the addition of chitosan (Stab Micro M).

KFV 2

Grapes were harvested on 8/14, chilled overnight, then whole cluster pressed using a gentle press cycle with the addition of 18 ppm SO2. Light pressings only were used for sparkling wine base. Cuvée was separated from taille after 2/3 the expected volume had been extracted. After two days of cold settling, juice was racked to neutral French oak barrels. The following day, juice was inoculated with 15 g/hL DV10 yeast rehydrated in 15 g/hL Oenostim. Juice was also chaptalized with 5 g/L sugar. At the completion of fermentation, 22 g/hL SO2 was added. Additional SO2 (2 g/hL) was added on 11/18 and 1/25.

T1: 15 g/hL Stab Micro M was added on 8/21/22

T2: 7 g/hL of Stab Micro M was added on 9/7/22

CO3

Fruit was harvested on 8/9, chilled overnight, then whole cluster pressed using a gentle press cycle with the addition of 19 ppm SO2. Light pressings only were used for sparkling wine base. Cuvée was separated from taille after 2/3 the expected volume had been extracted. After two days of cold settling, juice was racked to neutral French oak barrels. Juice was inoculated with 15 g/hL DV10 yeast rehydrated in 15 g/hL Oenostim on 8/14. Juice was also chaptalized with 10 g/L sugar and 1 g/L tartaric acid was added at this time. At the completion of fermentation, 22 g/hL SO2 was added. Additional SO2 (2 g/hL) was added on 11/18 and 1/25.

T1: 15 g/hL Stab Micro M was added on 8/19/22

T2: 7 g/hL of Stab Micro M was added on 9/15/22

Sensory analysis for this experiment was completed as two flights. Each flight was a comparison of a wine that did not undergo malolactic fermentation (“no ML”) with one that did (“full ML”). Flight 1 included wine from KFV 2 fruit while Flight 2 included wine from CO3 fruit. Sensory analysis was completed by a panel of 21 wine producers for flight 1 and 20 wine producers for flight 2. Wines were presented blind in randomly numbered glasses. Tasters were presented with three wines, two of one type and one of another, and asked to identify which wine was different (a triangle test). Participants were asked to identify which wine was different (a triangle test). There were four tasting groups per flight with the unique wine in the triangle test balanced among the groups. For both flights, participants were asked to score each wine on a scale of 0 to 10 for perception of acidity, perception of volatile acidity, lactic character, and volume/body. The descriptor “lactic character” was defined with specific terms “sauerkraut, parmesan cheese, yogurt, and butter”. They were also given open ended questions to describe the wines. Results for the triangle test were analyzed using a one-tailed Z test. Descriptive scores were analyzed using repeated measures ANOVA.

Results

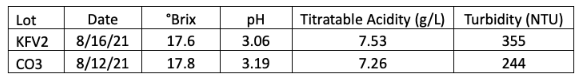

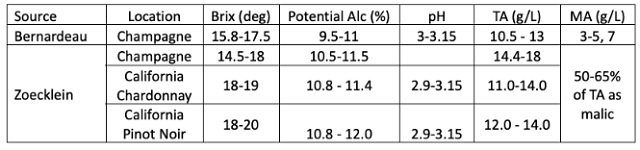

Both lots of fruit were harvested with chemistry consistent with use as sparkling wine base (Table 1), according to the guidelines put forth by Zoecklein1 and Bernardeau2 (Table 2). However, both lots had somewhat lower titratable acidity than recommended, and the pH of the CO3 lot was slightly higher than desired, both reasons to prevent malolactic fermentation.

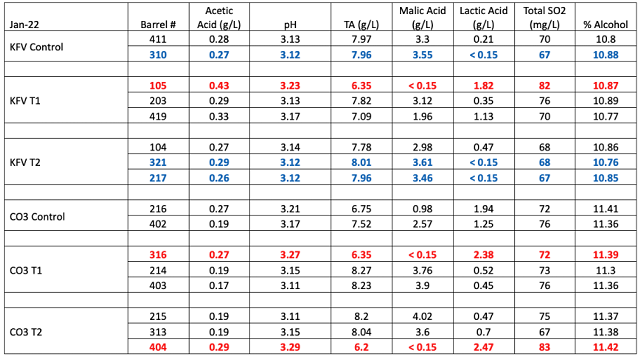

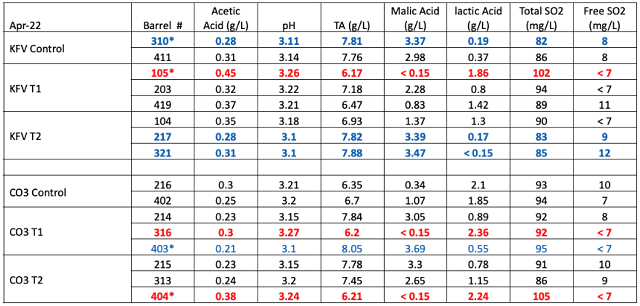

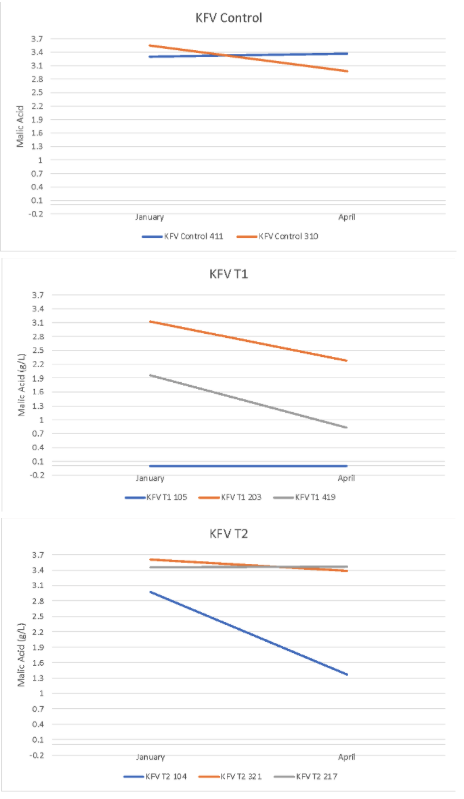

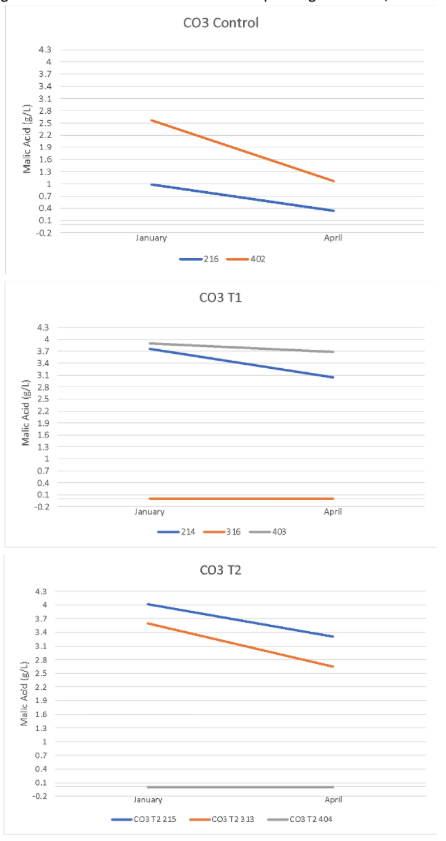

Fermentation kinetics were not affected by treatment (Figure 1, some data not shown). At the completion of fermentation, wine in several of the barrels had already undergone full malolactic conversion (Table 3, data shown in red), with 13 out of 16 of the barrels undergoing some malolactic fermentation. At the time of sampling in January, all barrels had total SO2 levels above 50 ppm, seen as a benchmark for preventing malolactic fermentation. Wine continued to decline in malic acid levels between January and April (Table 4, Figures 2 & 3). None of the treatments was sufficient to prevent malolactic fermentation in all of the replicates.

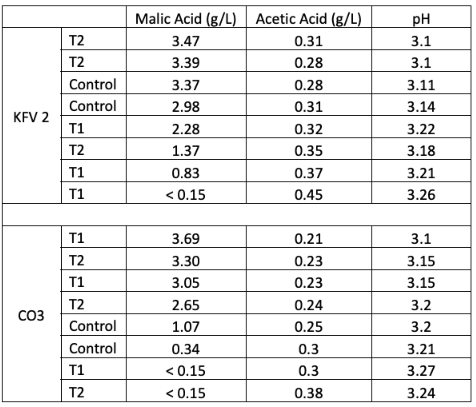

To determine if there was a consistent trend in malic acid fermentation based on treatment, barrels were sorted for levels of malic acid (Table 5). For both lots, as malic acid decreased, there was a general trend of increased pH and volatile acidity. Zoecklein (2002)1 recommends base wine to have a pH<3.3 and volatile acidity < 0.60 g/L for high quality sparkling production. All of the values shown here are still within that range. There was no consistent trend in malic acid depletion by treatment.

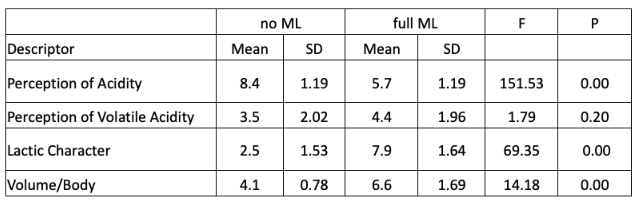

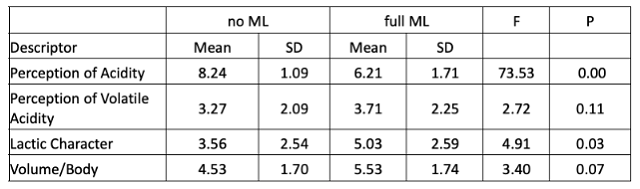

In a triangle comparing “no ML” to “full ML” wines from KFV2 fruit, 11 out of 21 respondents were able to distinguish which wine was different, indicating the wines were nearly significantly different (Z=1.62, p= 0.053). Malolactic fermentation led to significantly lower scores for acidity and significantly higher scores for lactic character and volume/body. Perception of volatile acidity was not significantly different. Open ended questions indicated that tasters felt the Chardonnay that went through full malolactic had lactic, or even cheesy characteristics (Table 6).

In a triangle comparing “no ML” to “full ML” wines from CO3 fruit, 17 out of 20 respondents were able to distinguish which wine was different, indicating the wines were significantly different (Z= 4.66, p= 0.00). Once again, the wine that underwent full malolactic fermentation had significantly lower score for perception of acidity and a significantly higher score for lactic character without significant differences in te perception of volatile acidity (Table 7).

Table 1: Fruit chemistry for two lots of sparkling wine base (in-house data)

Table 2: Fruit chemistry targets for sparkling wine base7-9

Figure 1: Fermentation kinetics for two lots of sparkling wine base (in-house data)

Table 3: General chemistry for several barrels of each treatment for two lots of sparkling wine base (ICV labs Jan 2022)

Table 4: General chemistry for several barrels of each treatment for two lots of sparkling wine base (ICV labs Jan 2022)

Figure 2: Change in malic acid for three treatments of sparkling wine base, Lot KFV2 (ICV labs)

Figure 3: Change in malic acid for three treatments of sparkling wine base, Lot CO3 (ICV labs)

Table 5: Relationship of treatment, malic acid, VA and pH (ICV Labs, April)

Table 6: Statistical analysis for descriptive scores from blind sensory analysis of Chardonnay

Table 7: Statistical analysis for descriptive scores from blind sensory analysis of Chardonnay

References

(1) Malolactic Fermentation: Importance of Wine Lactic Acid Bacteria in Winemaking; Morenzoni, R., Ed.; Lallemand Inc.: Montreal, 2015.

(2) O’Kennedy, K. Chitin, Chitinase, Chitosan ... Wineland Magazine, 2019.

(3) Malerba, M.; Cerana, R. Recent Advances of Chitosan Applications in Plants. Polymers 2018, 10 (2), 118.

(4) Barrett, L. Microbial Stability and Control: EnartisStab Micro (Chitosan) Application during Wine Maturation, 2019.

(5) Taillandier, P.; Joannis‐Cassan, C.; Jentzer, J.-B.; Gautier, S.; Sieczkowski, N.; Granes, D.; Brandam, C. Effect of a Fungal Chitosan Preparation on Brettanomyces Bruxellensis, a Wine Contaminant. Journal of Applied Microbiology 2015, 118 (1), 123–131.

(6) Chung, Y.; Su, Y.; Chen, C.; Jia, G.; Wang, H.; Wu, J. C. G.; Lin, J. Relationship between Antibacterial Activity of Chitosan and Surface Characteristics of Cell Wall. Acta Pharmacol Sin 2004, 5.

(7) Zoecklein, B. W. A Review of Methode Champanoise Production. Virginia Cooperative Extension 2002, No. Publication 463-017W.

(8) Bernardeau, M. Key Points to Sparkling Methode Traditionelle, 2017.

(9) Bernardeau, M. Base Wine Optimization Techniques: Key Tips for Award Winning Sparkling Rose Wines, 2018.