Comparing Wine Quality in Wines Produced in Conventional TBin vs. GOfermentor

Michael Heny

Michael Shaps Wineworks

Summary

The purpose of the WRE is to promote innovation through experimentation and education in the wine industry. This mandate includes testing and sharing outcomes with winemakers on new products and equipment. In 2019, the WRE was invited to take part in a collaborative study demonstrating the use of the GOfermentor. This piece of equipment includes a permanent base and single-use liner that uses programmed inflation to mix red wine fermentations. Benefits of this approach are thought to be less potential for microbial spoilage and less oxygen exposure. In this study, Chambourcin was fermented side by side in a GOfermentor and a TBin. There was little difference in finished chemistry between the two wines, with the GOfermentor wine showing slightly lower tannins and color. The overall impression of the users was that this technology may be helpful for a small winery with little staff and few fermentations, however for the larger winery, the need for complicated machinery and logistics of liner disposal were cumbersome.

Introduction

The purpose of the WRE is to promote innovation through experimentation and education in the wine industry. This mandate includes testing and sharing outcomes with winemakers on new products and equipment. In 2019, the WRE was invited to take part in a collaborative study demonstrating the use of the GOfermentor. The study was sponsored by the inventor of the product, including provision of the equipment and a stipend for grape purchases. All lab testing was done by the WRE.

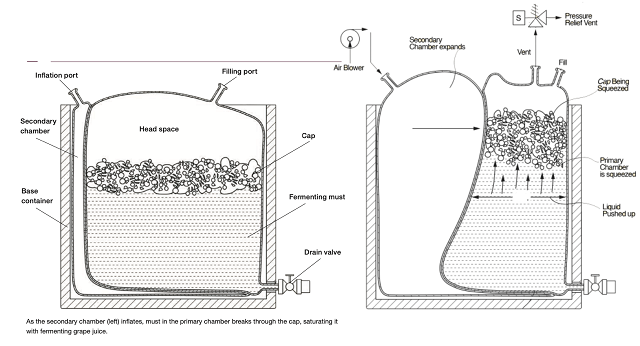

The GOfermentor is a one-ton fermentation vessel that includes a GOBase and GOliner. The GOBase is a large, rigid, reusable open topped container that looks much like a TBin. This base holds the GOliner, a recyclable plastic liner comprised of two connected chambers, one that holds must and one that inflates with air based on a programmed schedule. When the second chamber inflates, it pushes against the chamber holding must, effectively breaking up the cap and mimicking the action of a punchdown (Figures 1&2). Air inflation occurs on a timed schedule programmed into a controller box. The same squeezing mechanism can be used (under different instructions from the controller) to press juice at the end of fermentation. According to the manufacturer’s website, this air-filled chamber can also act as a bladder press for white grapes1,2. The website for the manufacturer (www.gofermentor.com) includes several helpful videos for understanding the functioning of this equipment.

The GOliner is filled through a port, so a must pump is the most efficient method to fill the liner. If a winery does not have a must pump, the bag can also be slit to fill directly, then resealed, however this leads to additional potential for oxygen ingress. The GOliner includes an exhaust port for CO2, a port for a temperature probe as well as a specialized port for sampling. The apparatus comes with a sampling gun that allows the winemaker to draw off a sample without opening the bag and exposing it to air. An additional accessory plate heat exchanger is also available for temperature control1,2.

According to the manufacturer’s website2, the Gofermentor offers several potential advantages. The GOliner itself is sterile, and is not re-used, meaning that no contaminating microorganisms are introduced into the fermentation from the fermentation vessel. The fermentation occurs in a closed environment, which precludes contamination from airborne microbes or fruit flies as well as excluding oxygen that leads to volatile acidity and oxidation of fruity thiols. Automation of the schedule for cap management frees up crew time and allows for more frequent management than is possible in most wineries. Less water is used in cleaning, as the GOliner is replaced for each fermentation. The liners themselves are made from a corn-based plastic without plasticizers, so they are 100% recyclable in principle.

There are, however, some potential drawbacks. Each GOfermentor costs $2500, uses a consumable liner for each fermentation and requires access to an outlet for proper functioning. In practice, recycling the liner involves thoroughly cleaning the bag of all pomace and shipping it back to the manufacturer for processing. The purpose of this study was to evaluate the ease of use and quality of resulting wine, including volatile acidity, phenolic extraction and varietal character as well as logistics of how well the GOfermentor fits into the workflow of a production scale winery. Two other trials were also run using the GOfermentor Junior to press white wine and attempt whole cluster fermentation. These are detailed in separate reports.

Methods

The standard procedure of the winery was employed for all winemaking operations with the sole exception of the fermentation vessel. Fruit was hand harvested and refrigerated overnight prior to destemming into a must pump, which pumped must into a TBin or the GOfermentor. Fermentations received 30 ppm SO2and 0.2 ml/L Color Pro (Scottlabs) at crush. Must was inoculated the following day with 0.15 g/L ICV GRE yeast rehydrated in GoFerm (Scottlabs). Cap management for the TBin included two punchdowns per day. The GOfermentor was programmed to also complete two punchdowns per day. Sugar (10 g/L) and DAP (0.5 g/L) were added on the third day of fermentation. Fermentation was monitored daily, and pressed at the completion of sugar depletion, after 7 days. The TBin was drained and pressed through a Europress. The GOfermentor was pressed using the built-in press function. Pressed wine was allowed to settle for one day prior to transfer to barrels of the same age and cooper for malolactic fermentation. Wine was treated with sulfur dioxide after completion of malolactic fermentation, roughly one month later. SO2 was monitored monthly with adjustments to a common target free SO2.

Results

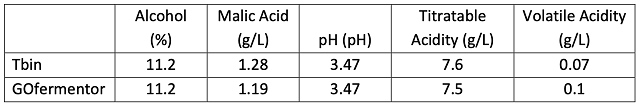

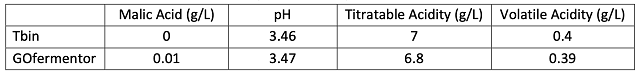

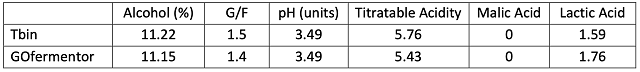

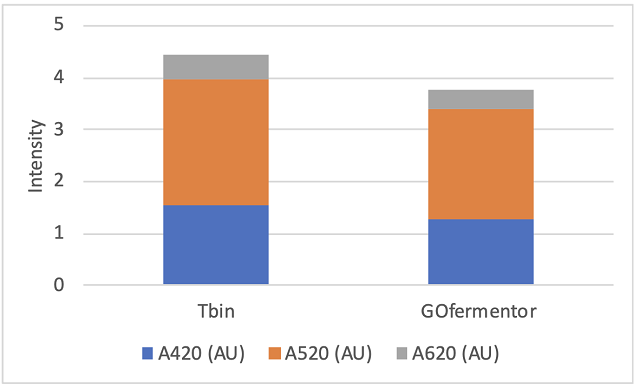

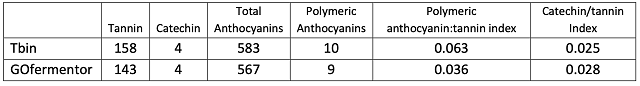

Grapes were harvested with 19.3°Brix, pH of 3.21 and TA of 7.6 g/L. Both lots completed alcoholic fermentation in 7 days, with very similar chemistry after pressing (Table 1). Both lots completed malolactic fermentation by 10/31, within 6 weeks of pressing. Chemistry of the wines was again very similar (Table 2). Chemistry after aging assessed by an outside lab had some differences from in-house data, most notably the level of residual sugar (Table 3). These data were taken after three months, during which time considerable volatile acidity had accumulated. Differences in titratable acidity from initial are likely due to loss of CO2 after fermentation. Wine fermented in the GOfermentor had slightly less color intensity (Figure 1), with an overall intensity of 3.77 compared to 4.44 for the TBin fermented wine. The manufacturer pointed out that the suggested program for red wine fermentation is not two punches per day, as was used in this study, but four, allowing for greater extraction of phenolics and color, so lower color may be due to fewer cycles of squeezing than the manufacturer recommended. However, color may also have been affected by lower overall oxygen availability during fermentation. Oxygen contributes to color fixation. The wine fermented in the GOfermentorhas lower tannin, anthocyanin, ratio of polymeric anthocyanin:tannin. Both wines had very low proportion of polymeric anthocyanins, so the ratio difference is due to lower tannin in the GOfermentor.

Impressions of the user and manufacturer response

The users felt that, once the unit was set up, it was easy to use. However, they encountered some difficulties with the equipment early on. The venting assembly appeared to be cracked, which might have interfered with the effectiveness of punchdowns (the wine bag built up notable pressure due to lack of venting, not allowing adequate breakup of the cap). There was also some concern about the disposal of the bag. In the normal flow of the winery, a pomace pile is used to dispose of spent grape materials. In this case, those materials were in a biodegradable plastic bag, which could not be added to that pile (which is subsequently used for fertilizer). In general, though the GOfermentor may be a great option for a smaller winery, it did not fit well in the workflow of this larger winery. The manufacturer pointed out that the suggested program for red wine fermentation is not two punches per day, as was used in this study, but four, allowing for greater extraction of phenolics and color.

Figure 1: Setup and cap management of the GOfermentor (from https://www.gofermentor.com)

Figure 2: A GOfermentor in action

Table 1: Post-alcoholic fermentation chemistry for wines fermented in TBin and GOfermentor (in-house data)

Table 2: Post-malolactic fermentation chemistry for wines fermented in TBin and GOfermentor (in-house data)

Table 3: Chemistry after three months of aging for wines fermented in TBin and GOfermentor (reported in g/L unless otherwise noted)(ICV Labs)

Figure 3: Color intensity for wines fermented in TBin and GOfermentor (ICV Labs)

Table 4: Phenolic measurements for wines fermented in TBin and GOfermentor (mg/L)(ETS Labs)

References

(1) Carey, R. GOfermentor Enables Quality Improvement. Wines and Vines, 2016.

(2) Gofermentor, a revoluion in winemaking https://www.gofermentor.com.