Comparing chemical and sensory effects of destemmer rate in Cabernet Franc and Petit Verdot (2021)

Kirsty Harmon

Blenheim Vineyards

Summary

Most wineries destem red grapes as part of standard operations for red wine processing. Destemming operations require adjustments based on the type and quality of the fruit. In this experiment, the auger speed (feed rate) was varied from 1 (slow) to 5 (fast) while basket speed remained the same (6), leading to an estimated difference in production speed of 2 tons/hour vs. 5 tons/hour. The experiment was conducted for both Cabernet Franc and Petit Verdot. There were no measurable differences in wine chemistry or phenolics between treatments in either variety. There were also no sensory differences between the wines as measured with a triangle test or descriptive scores. In this case, faster operations had no negative impact on wine quality.

Introduction

The purchase of a destemmer is one of the most expensive, but potentially most impactful purchases a winery makes. Most wineries destem red grapes as part of standard operations for red wine processing. By removing stems from grapes prior to fermentation, the winemaker minimizes the uptake of unwanted stem materials such as phenols, lipids, potassium and water1,2. Stems can also contain hexanol and other C6 compounds that lead to “leafy” vegetal perception.

Most modern destemmers use a mechanism consisting of a cylindrical cage with perforated sides coupled with rubber-tipped beaters arranged in a spiral pattern along a circular axis to remove grapes from stems. In this arrangement, grapes are drawn into the cage by the rotation of a central auger. Once in the cage, the beaters press the grapes against the sides of the cage. The grapes are small enough to exit through the perforations while stems are moved down the cage by the rotation of the arms. Stems exit through the far end of the cage while grapes drop through the perforations into the waiting fermentation vessel1,3.

Several characteristics of destemmer construction have been shown to affect resulting wine quality. Beaters with rubber tips are gentler and lead to less breakage of berries and stems than steel tipped beaters3,4. If the basket and auger rotate in opposite directions, removal of berries is more efficient, however, there is more shearing and pinching between the cage and the shaft, leading to stem breaks and berry damage5,6. If perforations in the side of the cage are larger in size, more jacks may be able to sneak through, however, if they are too small, more berries are ejected out the end of the cage with the stems3. Destemmers also function more efficiently when they are near capacity, as this keeps grapes from spending too much time in the cage, which allows more jacks to sneak through3.

Despite which destemmer is purchased, adjustments must always be made based on the fruit material itself. Higher overall application of energy (faster speed) will lead to more berries separated from their stems, however this same energy will potentially lead to stem and seed breakage3,5. Most destemmers allow for adjustment in the speed of both the shaft (feed rate and beater rotation) and the basket. The cage should rotate slower than the shaft7. Too slow of a feed rate leads to stems and berries spending too long in the cage, leading to greater quantity of stalk debris (jacks) in the fermentation vat. However, if beaters rotate too quickly, berries burst and stalks shred7–9. Christman5 recommends a ratio of speed between the shaft and the basket between 1:8 and 1:10 with shaft rotation at 350-500rpm (but, others recommend 220-260 rmp9). Unfortunately most destemmer speed dials are not labeled in a way that allows for this determination. Taken all together, practically this means:

-

If you have too many berries ejecting from the end of the cage, you may need to increase the beater speed or switch to a cage with larger perforations.

-

If you have too many burst berries or shredded stalks (jacks), try decreasing the speed of the beaters.

One last parameter that affected wine quality was the rate of fruit delivery. “Overfeeding”, meaning fruit delivery that occurred too quickly, led to machine jamming as well as variable rates of movement through the shaft, with too rapid movement when just after fruit loading and too slow fruit movement in between fruit loading events. For this reason, it is better to use a fruit conveyer or have a person raking fruit into the hopper than delivering fruit from harvest bins all at once.

Blenheim vineyards purchased a new destemmer before the 2021 harvest. When optimizing the settings, an attempt was initially made to try to reduce the amount of jacks entering red wine fermentations and maximizing the proportion of uncrushed whole berries. Initial inquiries to the manufacturer resulted in a recommendation to run the destemmer at 2 tons/hour. However, this slow speed was likely to impact processing when larger volumes of fruit were harvested. The purpose of this experiment was to determine if faster destemmer speed led to higher levels of astringency and bitterness and lower fruitiness associated with increased jacks and added crushing of fruit. As different varieties have different physical properties, the same protocol was followed for Cabernet Franc and Petit Verdot.

Methods

Cabernet Franc

Cabernet Franc fruit was harvested from Reeds Vineyard in Lynchburg, Virginia on 9/25, refrigerated overnight before processing. Lugs were unloaded onto a gooseneck conveyor without sorting for transport to the destemmer.

A Scharffenberger AS 05 destemmer with a polyethylene basket was used for this experiment. There is no crusher on this destemmer. The machine has separate speed controls for basket speed(1-9) and auger speed(1-10). For this experiment, the auger speed (feed rate) was varied. For the "slow" treatment the auger was set to 1 and the basket speed was set to 6. For the "fast" treatment the auger speed was increased to 5 (out of 10) and the basket speed remained the same at 6. The elevator speed for both treatments was adjusted to avoid overloading the hopper, with an estimated 2 tons/hour for the slow treatment and approximately 5 tons/hr for the fast treatment.

Fruit was processed into TBins with the addition of 50 mg/L SO2, then placed in a climate controlled warehouse overnight. Bins were inoculated with 75 g EC1118 per bin (0.14 g/L with an estimated 515 liters per bin) the next day, along with addition of 1.36 g/L tartaric acid. Bins were punched down twice daily with addition of 7 g/L sugar two days after inoculation. Fermentation was complete on 10/11. Bins were pressed at the completion of fermentation. For the experiment, free run wine was removed from the bins and sent to barrels prior to pressing, then inoculated for malolactic fermentation with 1 mg/L MBR Process. Malolactic fermentation was complete on 10/26. SO2 (100 mg/L) was added on 11/8 and wine was aged on lees until sensory analysis.

Petit Verdot

Petit Verdot fruit was also harvested from Reeds Vineyard in Lynchburg, Virginia on 9/25, refrigerated overnight before processing. All processing methods were the same as for Cabernet Franc with the exception of addition rates. Petit Verdot received 1.04 g/L tartaric acid and was not chaptalized.

Sensory Analysis

Sensory analysis was conducted in two flights, one for each variety. For each, wines were evaluated by a panel of 17 wine producers. Wines were presented blind in randomly numbered glasses. Tasters were presented with three wines, two of one type and one of another, and asked to identify which wine was different (a triangle test). There were three tasting groups with the unique wine in the triangle test balanced between groups. Tasters were then asked to score each wine on a scale of 0 to 10 for fruit intensity, green character, bitterness, and astringency. They were also given open ended questions to describe the wines. Results for the triangle test were analyzed using a one-tailed Z test. Descriptive scores were analyzed using repeated measures ANOVA.

Results

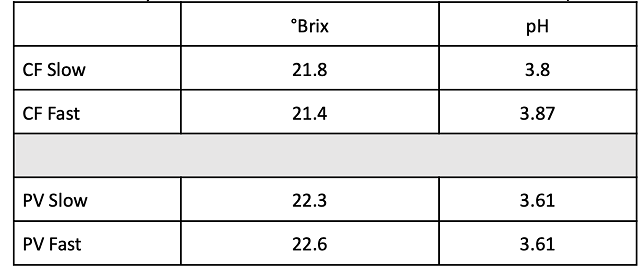

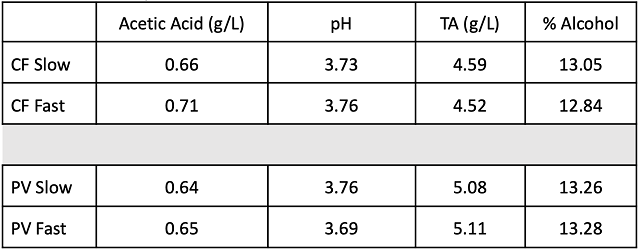

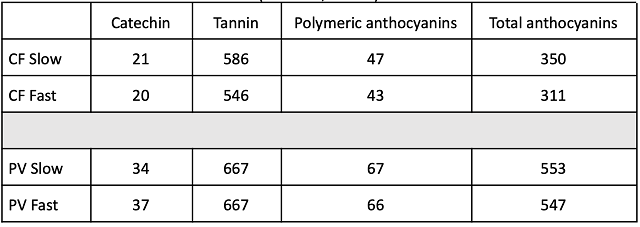

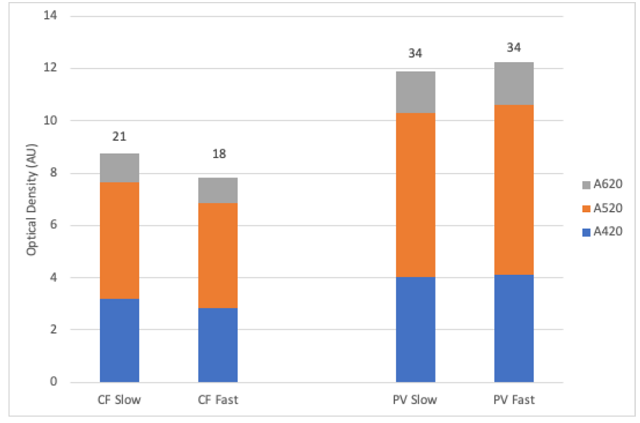

There were no notable differences in beginning fruit chemistry between treatments in Cabernet Franc nor Petit Verdot (Table 1). The experimenter noted that there were no large observable differences in the appearance of the must after processing (i.e. There were not more jacks or more shredded fruit in the fast treatment). Wine chemistry (Table 2) and phenolic measurements (Table 3) were also nearly identical between treatments.

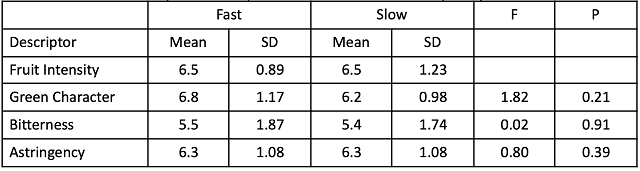

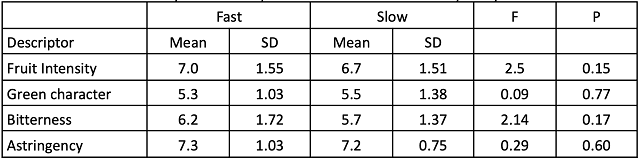

In a triangle test of comparing fast vs. slow treatments of Cabernet Franc, 7 out of 17 respondents were able to distinguish which wine was different, indicating the wines were not significantly different (Z=0.43, p= 0.33). There were also no significant differences in scores for fresh intensity, green character, bitterness, or astringency (Table 4). In the triangle comparing fast vs. slow treatment of Petit Verdot, 6 out of the 17 respondents were able to distinguish which wine was different, indicating the wines were also not significantly different (Z=-0.09, p= 0.50). Again, there were no significant differences in scores for fruit intensity, green character, bitterness or astringency (Table 5). Based on these findings, there was no measurable advantage to slower destemmer feed rate.

Table 1: Fruit chemistry for two treatments of Cab Franc and Petit Verdot (in-house data)

Table 2: Wine chemistry for two treatments of Cab Franc and Petit Verdot (ICV Labs, March)

Table 3: Phenolic measures (mg/L) for two treatments of Cab Franc and Petit Verdot

(ETS Labs, March)

Figure 1: Color intensity for two treatments of Cabernet Franc and Petit Verdot (ICVLabs, March). Free SO2 values (mg/L) at the time of sampling are listed at the end of the columns.

Table 4: Statistical analysis of descriptive scores from blind sensory analysis of Cabernet Franc

Table 5: Statistical analysis for descriptive scores from blind sensory analysis of Petit Verdot

References

(1) Jackson, R. S. Wine Science: Principles and Applications, 4 edition.; Academic Press: Amsterdam, 2014.

(2) Ribereau-Gayon, P.; Dubourdieu, D.; Doneche, B.; Lonvaud, A. Handbook of Enology Volume 1: The Microbiology of Wine and Vinifications, 2nd ed.; John Wiley & Sons: West Sussex, England, 2006.

(3) Phillips, C. Product Review: Destemmers. Wine Business Monthly 2005, June, 1.

(4) Catania, P.; Pasquale, C. D.; Morello, G.; Vallone, M. Influence of Grape Transport and Destemming Systems on the Quality of Chardonnay Wines. 2016, 8.

(5) Christmann, M.; Freund, M. Chapter 15 Advances in Grape Processing Equipment. In Managing Wine Quality Volume 1: Viticulture and wine quality; CRC Press, Woodhead Publishing Limited: New York, 2010.

(6) Destemming and Crushing Guidebook.

(7) Nordestgaard, S. Developments in Destemming and Sorting Technology. Grapegrower and Winemaker. June 2015, pp 97–102.

(8) Visonneau, E.; Vergnes, M. Chapitre 1: Etude Des Conditions d’utilization d’un Erafloir 1995-1997; Banque de donées des marériels viti-vinicoles; 2000.

(9) Visonneau, E.; Vergnes, M. Chapitre 5: Incidence de La Qualité de l’eraflage Sure al Qualité Des Vines; Banque de donées des marériels viti-vinicoles; 2000.