The Effect of Toasted and Untoasted Oak Chips and Granular Oak Additions to Red Must (2016)

Emily Pelton

Veritas Vineyards and Winery

Summary

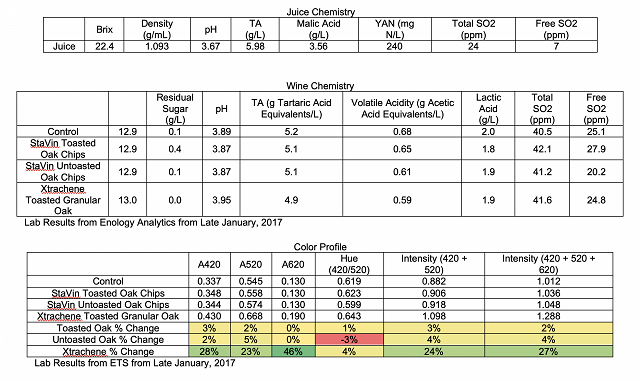

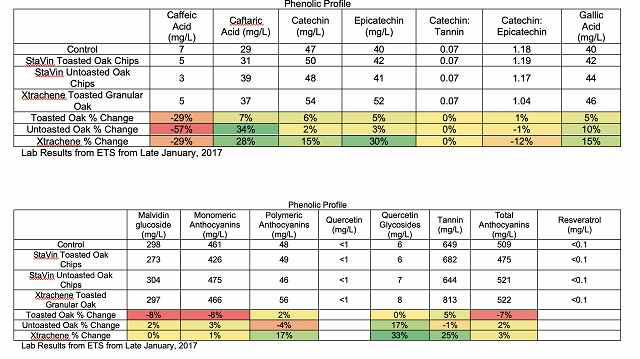

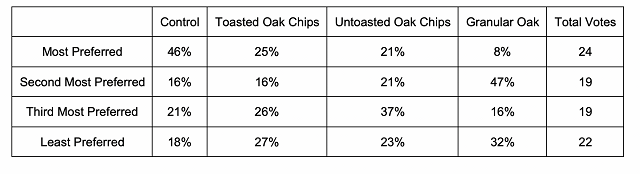

This study examines the impact of toasted and untoasted granular oak additions to Petit Verdot must. Petit Verdot grapes were sourced identically and processed identically into 4 separate fermentation vessels, one without oak additions, one with untoasted oak chip additions, one with toasted oak chip additions, and one with Xtrachene medium toast French granular oak additions. All other treatments were kept the same between wines. The Xtrachene granular oak exhibited the greatest increase in color intensity, tannin content, and polymeric anthocyanins (suggesting more color stability). Color was only slightly improved by oak chips. Untoasted oak chips and Xtrachene toasted granular oak exhibited an increase in caftaric acid, catechin, epicatechin, and gallic acid. Oak consistently lowered caffeic acid, although the numbers are very small. Anthocyanin extraction was not enhanced by oak, and was even lowered by toasted oak chips. In general, oak saw increases in color, catechin, epicatechin, and tannin, with granular oak resulting in the largest increases. In general, people preferred the control wine. The second-most preferred and least-most preferred wines were made with Granular Oak. No strong trends were found for the descriptors used in this study. The Granular Oak treatment seemed to increase Bitterness, Fruit Intensity, and Astringency more than the other treatments. Toasted Chips appeared to increase Fruit Intensity, along with Granular Oak. However, these tendencies were weak. Wines made with Granular Oak were often described as being oaky or smoky.

Introduction

Oak adjuncts are often marketed to add volume to the palate, reduce vegetal characters, increase fruit character, and help with anthocyanin stability (Mitham 2010; Xtrachêne 2015; StaVin Inc.). Although they can impart oak aromas, not all kinds of oak adjuncts are marketed to have this impact. Untoasted oak, for example, may contain more hydrolysable tannins while imparting less oak aroma to wines. Additionally, the extractability of oak is measured in great part by the surface area of the adjunct, with granular oak having the highest level of extractability (Xtrachêne 2015; StaVin Inc.).

Although some have found that wine aged with oak chips tends to result in quicker development of polymerized tannin and overall aging factors than wine aged in barrels (del Alamo Sanza et al. 2004), others have found that the effects of adding oak chips to must do not result in consistent organoleptic and phenolic qualities, and are often indistinguishable from control wines (Zimman et al. 2002; García-Carpintero et al. 2011). In one study, oak chips during fermentation had no discernable effect, and varied depending on the site and fermentation. Some fermentations showed decreases in color and polymeric pigment, but others showed increases. In general, free anthocyanins decreased from the use of oak chips, possibly due to adsorption onto the oak chips (Zimman et al. 2002). This study had poor replications and variable control, however. In another study, oak chips reduced the extraction of total phenols during fermentation, although phenolic composition did not differ greatly between treatments (Zimman et al. 1999).

Ellagic acid and other oak constituents may act as antioxidants, protecting other phenolic compounds from degrading (Vivas and Glories 1996; Puech et al. 1999). It does not appear that polymeric, stable pigment derived from oak tannins are formed; however, the study in question was was performed on model wine and the necessary precursors were just not available for the formation of polymeric pigment (Jordão et al. 2006). This antioxidant effect of ellagic acid could be an indirect mechanism for the formation of stable polymeric pigment from oak extracts. Indeed, one study found that ellagic tannins speed up the condensation of procyanidins and reduce the degradation of condensed tannins and anthocyanins (Vivas and Glories 1996) (this reduction of tannin degradation is contrary to the findings of Jordão et al. 2006). Ellagic tannins are more oxidizable than some wine phenolic compounds such as catechin, due to more hydroxyl groups in ortho positions per mole. However, these ellagitannins are also stronger oxidants, which result in more peroxide production and thus more aldehyde production. This may improve the formation of polymeric pigment during wine aging through acetaldehyde bridging. However, solutions with both catechin and ellagitannins produce less peroxides and consume oxygen slower than solutions with these compounds on their own. The authors suggest this rapid consumption of oxygen, followed by a large inhibition in consumption, is due to competitive inhibition of catechin with ellagitannins (Vivas and Glories 1996). This explanation needs further study: there must be some way in which the two compounds together inhibit iron cycling. The authors also suggested that ellagic tannins may act as antioxidants to protect catechin. Regardless, in this study ellagic tannins increased color intensity, helped form polymeric pigment, and led to decreased browning compared to oxidizing a control wine (Vivas and Glories 1996).

The effects of oak tannin on color stability in wine from true oak is also questionable. Condensed tannins are present only in low levels in oak heartwood, and are not likely to contribute much to wine, because wine has high levels of these naturally from grapes and the contribution from oak would be minimal (Puech et al. 1999). Condensed tannins (flavan-3-ols) are the phenolic compounds that are most responsible for forming polymeric pigment in wine. Ellagitannins are hydrolysable tannins, and it is unclear from a mechanistic sense how they would polymerize with anthocyanins. Furthermore, ellagitannins are only found in very low levels in oak-aged wines, despite being highly soluble. Toasting wood reduces the levels of ellagitannins at the toasting layer, resulting in less available to be extracted. Additionally, wines extract much less ellagitannins from wood than would be expected theoretically. Ellagitannins may also interact with polysaccharides and yeast proteins and mannoproteins, and as a result may be fined out of wine with yeast lees. Polymerization products are generally not from ellagitannins, and instead of polymerizing with anthocyanins and phenolics they appear to react with ethanol to form hemiketal derivatives. This also seems to occur instead of their reacting with oxygen and scavenging radicals, suggesting that their antioxidant effect may not be as pronounced as was previously thought (Puech et al. 1999).

Although winemakers use oak in part to stabilize color, it appears that the main benefit in oak adjunct use in winemaking is to mask or adsorb unwanted aromatics in wine, such as vegetal aromas. It is unlikely that much stabilization occurs from oak chips, due to the low concentrations of hydrolysable tannin that is added and because furfural, an oak compound that can condense with anthocyanins, is extracted at low concentrations as well. Additionally, some mouthfeel effects from oak also seem possible (Mitham 2010). However, added color stability is possible, but consistency in these results seems to be lacking. Oak adjuncts, in general, are very inconsistent in their results. This study examines the impact of different sources and kinds of oak added during crush on the chemical and sensory properties of wine.

Results and Discussion

The Xtrachene granular oak exhibited the greatest increase in color intensity, tannin content, and polymeric anthocyanins (suggesting more color stability). Color was only slightly improved by oak chips. Untoasted oak and Xtrachene toasted oak exhibited an increase in caftaric acid, catechin, epicatechin, and gallic acid. Oak consistently lowered caffeic acid, although the numbers are very small. Anthocyanin extraction was not enhanced by granular oak, and was even lowered by toasted oak. In general, oak saw increases in color, catechin, epicatechin, and tannin, with granular oak resulting in the largest increases. In general, people preferred the control wine. The second-most preferred and least-most preferred wines were made with Granular Oak. No strong trends were found for the descriptors used in this study. The Granular Oak treatment seemed to increase Bitterness, Fruit Intensity, and Astringency more than the other treatments. Toasted Chips appeared to increase Fruit Intensity, along with Granular Oak. However, these tendencies were weak. Wines made with Granular Oak were often described as being oaky or smoky.

Methods

Petit Verdot fruit was hand harvested into harvest bins and then stored in refrigerated trucks overnight at a temperature of around 40°F. The following day the fruit was processed through a destemmer and across a sorting table into three separate T-bins. During the destemming process the 1st bin received 5.5g/L (8 pounds per ton) of Stavin untoasted oak chips gradually as the bin filled (French oak, seasoned 3 years). The second bin received 5.5g/L (8 pounds per ton) of Stavin toasted oak chips, added gradually as the bin filled (toasted French oak, 3 years seasoned). The 3rd bin received no addition of oak and become the control for the trial. The 4th bin received 4g/L Xtrachêne toasted French granular oak (aged two years and thermally treated).

The bins once full were moved into refrigerated trucks where they began 1-2 days of cold soak. The bins received enzyme Color Pro at 80ml/ton and were then moved into a heating trailer and warmed to around 65°F. Once at the required temperature yeast ICV D254 was added at 20g/hL along with Fermoplus Energy Glu at 5 g/hL to begin active fermentation. Both temperature and Brix were recorded daily. All four T bins were treated the same with 3 punch downs daily during mid fermentation and 2 towards the end of the ferment. Fermentation and cold soak took a period of 10 days, after which these wines underwent an extended maceration from 10/18-11/15. Halfway through extended maceration, malic acid had dropped to 1.68 g/L. The bins were gassed daily with argon. The bins were all pressed off on the same day (11/15) to ensure equal maceration times.

The wine was then moved into four identical red neutral barrels for ageing. ML bacteria PreAc 450 was added at 1g/hL to begin malolactic conversion. Once the wine had completed malolactic conversion (11/21), 40ppm of sulfur dioxide was added to protect the wine as it ages. On 11/22 0.5 g/L tartaric acid was added. On 12/6 another 0.5 g/L tartaric acid was added.

This project was tasted on April 26. In order to balance the data set to perform statistical analysis for descriptive analysis, any judge who had not fully completed the descriptive analysis ratings were removed. In order to then make the amount of judges between groups equivalent, one judge from group 1 was transferred to group 2, and 2 judges from group 1 was eliminated. This resulted in a final data set of 3 groups, each with 4 judges (considered as replications within groups, and groups were considered as assessors). Data was analyzed using Panel Check V1.4.2. Because this is not a truly statistical set-up, any results which are found to be statistically significant (p<0.05) will be denoted as a “strong trend” or a “strong tendency,” as opposed to general trends or tendencies. The statistical significance here will ignore any other significant effects or interactions which may confound the results (such as a statistically significant interaction of Judge x Wine confounding a significant result from Wine alone). The descriptors used in this study were Fruit Intensity, Herbaceous/ Green, Overall Aromatic Intensity, Bitterness, Astringency, and Body.

References

del Alamo Sanza, M., Domínguez, I.N., Cárcel, L.M.C., and Gracia, L.N. 2004. Analysis for low molecular weight phenolic compounds in a red wine aged in oak chips. Analytica Chimica Acta. 513:229-237.

García-Carpintero, E.G., Gallego, M.A.G., Sánchez-Palomo, E., and González-Viñas, M.A. 2011. Sensory descriptive analysis of Bobal red wines treated with oak chips at different stages of winemaking. Australian Journal of Grape and Wine Research. 17: 368-377.

Jordão, A.M., Ricardo-da-Silva, J.M., and Laureano, O. 2006. Effect of oak constituents and oxygen on the evolution of malvidin-3-glucoside and (+)-catechin in model wine. Am. J. Enol. Vitic. 57:377-381.

Mitham, P. 2010. Oak adjuncts in red ferments. How winemakers add oak early to improve aroma and texture. Wines and Vines. September. https://www.winesandvines.com/template.cfm?section=features&content=78082 Accessed 2/7/2017.

Puech, J.-L., Feuillat, F., and Mosedale, J.R. 1999. The tannins of oak heartwood: structure, properties, and their influence on wine flavor. Am. J. Enol. Vitic. 50:469-478.

StaVin Inc. Fermentation Oak Chips and Granular. http://www.stavin.com/tank-systems/fermentation-oak-chips-and-granular. Accessed 2/7/2017.

Vivas, N. and Glories, Y. 1996. Role of oak wood ellagitannins in the oxidation process of red wines during aging. Am. J. Enol. Vitic. 47:103-107.

Xtrachêne. 2015. Catalogue. http://www.xtrachene.fr/images/actualites/XC-Catalogue-EN.pdf. Accessed 2/8/2017.

Zimman, A., Fennedy, J.A., Joslin, W., Lyon, M.L., Meier, J., and Waterhouse, A.L. 1999. Phenolic extraction in commercial scale maceration trials II. American Journal of Enology and Viticulture. 50:364-384. Abstracts and Reviews.

Zimman, A., Joslin, W.S., Lyon, M.L., Meier, J., and Waterhouse, A.L. 2002. Maceration variables affecting phenolic composition in commercial-scale Cabernet Sauvignon winemaking trials. Am. J. Enol. Vitic. 53:93-98.