Moderating acidity with malolactic fermentation in sparkling wine base (2020)

Matthieu Finot

King Family Vineyards

“Sparkling wines can be made in different ways but they all have one thing in common: the quality of the sparkling wines always depends on the quality of the base wine”1.

(Maximilien Bernardeu, Station Oenotechnique de Champagne)

Summary

In 2020, King Family Vineyards harvested Chardonnay for sparkling wine base with higher pH and lower Brix than would normally be desired for sparkling wine base. Much of the acidity was also attributed to malic acid. Concern arose that this base wine, once acidulated to assist in microbiological stability, would have a very high TA and unbalanced acidity. In this experiment, several barrels of sparkling wine base were allowed to go through malolactic fermentation to determine if shifting the acid profile would produce a more pleasing acid balance. Two separate lots were used, with several barrels per lot. Malolactic fermentation led to higher volatile acidity (0.27 g/L in control vs. 47 g/L in wine that went through malolactic) as well as higher pH (3.18 v.s 3.43). Wines were significantly different in a triangle test, however they did not have any decrease in the perception of acidity. Malolactic fermentation shifted the chemical profile away from that which is most desired for sparkling wine base without the desired change in sensory characteristics, and is therefore not desired in this application.

Introduction

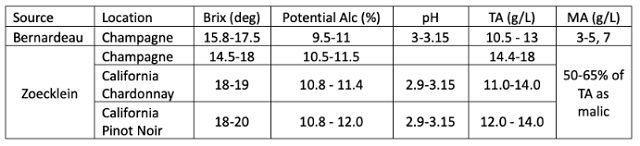

Good quality sparkling wine is produced all over the world from many different grape varieties. Despite the diversity of origin, most quality sparkling producers follow a similar set of general principles for the production of the base wine. Some of these principles are the same as would be employed for the production of still wines, but some are different because of the way this wine will eventually be utilized. The overall winemaking goal for sparkling wine base is the production of a fresh, elegant, clean wine with low aromatic or varietal character1,2. Decisions made at each step of grape processing help achieve these overall winemaking goals. Grapes are harvested early to retain acidity (freshness) and prevent rot4. The decision when to harvest is made based on fruit chemistry targets (Table 1) as well as the condition of the fruit. If the fruit is underripe, it may lead to vegetal characteristics which will be amplified when sparkled, however if it is overripe, it may lead to heaviness not desired for sparkling1–4. In warm regions, a sugar: acid ratio of 15-20 (with sugar expressed in grams per liter) may be used as a guideline for harvest decisions3.

Table 1: Fruit chemistry targets for sparkling wine base1–3

Sparkling wine grapes are pressed as whole clusters to minimize maceration with skins that might decrease the pH and increase phenolics (which lead to bitterness and browning), minimize pigment extraction and extraction of polyphenoloxidase enzymes found in skin. Pressing as whole clusters also allows stems to assist in drainage during a gentle press program1,2,4. Most modern presses include a program for pressing sparkling wines. These programs are designed to be gentle enough to extract pulp with little incorporation of skin components. The volume of juice recovered during gentle pressing (cuvée) is used for sparkling wine base while juice extruded during the later part of the program (taille) is diverted for other uses. The diversion decision may be based on press pressure (usually at 100kPa or 1 bar), target volumes, a shift in pH, or shift in the flavor profile1,3. In Champagne, 2550 liters of juice is expected from 4 metric tons of grapes. It is expected that 2050 liters will be used for cuvée and the remaining 500 liters will make up the taille1,2.

In many ways, the fermentation of sparkling wine base is the same as for still wine. Fermentation can occur in stainless steel vessels or in neutral oak barrels, which add structure to the wine3. Newer oak barrels are usually avoided as tannins and oak flavors are not desired. Cooler fermentation temperatures lead to development of fruity and floral aromatics desired for sparkling Rosé while warmer temperatures lead to more austere aromatic profile with less floral character more desired for Brut style sparkling3.

Some sparkling wine producers allow the base wine to undergo malolactic fermentation while others do not1,3,4. This decision is likely driven both by stylistic concerns as well as base chemistry of the wine. Overall acidity levels may be much higher in cooler regions or vintages than warm ones, leading to a desire for malic acid depletion in cooler regions and retention in warmer regions3. Malic acid is generally thought to have more aggressive acidity than lactic acid, so malolactic fermentation can be used to modify the palate structure of the base wine3. Malolactic fermentation also allows for a more microbially stable product during bottle aging. However, wines that undergo malolactic fermentation often have higher levels of volatile acidity, due to the activity of the bacteria as well as longer time post fermentation prior to the addition of SO21. For more aromatic sparkling Rosé, malolactic fermentation is generally avoided2.

In 2020, King Family Vineyards harvested a large lot of Chardonnay over the course of more than a week. This fruit came in with higher pH and lower Brix than would normally be desired for sparkling wine base. Much of the acidity was also attributed to malic acid. Concern arose that this base wine, once acidulated to assist in microbiological stability would have a very high TA and unbalanced acidity. The decision was made to break the lot into three treatments and examine the chemical and sensory differences for each:

-

Tank fermentation without malolactic fermentation

-

Neutral barrel fermentation without malolactic fermentation

-

Neutral barrel fermentation with malolactic fermentation

Methods

Grapes were harvested on 8/20, chilled overnight, then whole cluster pressed with the addition of 23 ppm SO2. Light pressings only were used for sparkling wine base. Cuvée was separated from taille after 2/3 the expected volume had been extracted. The following day, 100 g/hL cream of tartar was added to precipitate excess tartaric acid. After two days of cold stabilization and settling, juice was racked to a stainless steel tank and several neutral French oak barrels. Juice was chaptalized with 30 g/L sugar and acidulated with 1.5 g/L tartaric acid at racking. The following day, juice was inoculated with 13 g/hL DV10 yeast. Bentonite (20 g/hL) and casein (10 g/hL) were added mid fermentation. The barrels also received an additional 18 g/L sugar mid fermentation while the tank did not.

For the tank fermentation and the barrels not designated for malolactic fermentation, 3 g/hL of Stab Micro M and 3 g/hL SO2 were added at the completion of alcoholic fermentation. For the barrels designated for malolactic fermentation, these additions were made after malic acid depletion was complete. Additional SO2 (22 g/hL) was added during aging. The tank was aged on lees with no stirring. Barrels were stirred once per week.

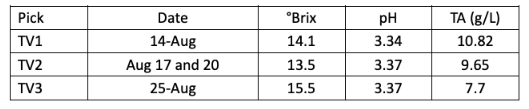

This experiment was conducted in two different lots of wine, from the same vineyard, picked up to a week apart (Table 2). Eight barrels were analyzed for each lot, with paired barrels of the same cooper and age in each treatment. Wine analysis is reported for both lots; sensory analysis was conducted on the TV2 lot only.

Sensory analysis of this experiment contained two flights. Sensory analysis of wine with alcoholic fermentation only vs. wine that went through full malolactic fermentation was completed by a panel of 26 wine producers (Flight 1). Comparison of wine fermented in a tank vs. a neutral oak barrel (Flight 2) was completed by 21 wine producers. Due to restrictions put in place during COVID-19, sensory analysis was completed using shipped samples. Each wine producer received three wines in identical bottles, filled on the same day, each coded with random numbers. Two of the bottles contained the same wine while the third bottle contained the different wine. Participants were asked to identify which wine was different (a triangle test). There were four tasting groups with the unique wine in the triangle test balanced among the groups. Participants were then asked to score each wine on a scale of 0 to 10 for fruit intensity, perception of acidity, lactic character, and volume/body. They were also given open ended questions to describe the wines. Results for the triangle test were analyzed using a one-tailed Z test. Descriptive scores were analyzed using repeated measures ANOVA.

Results

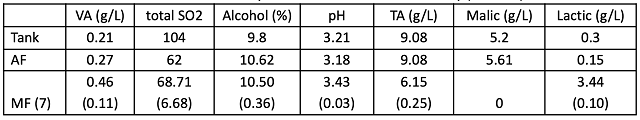

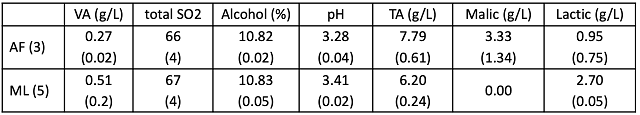

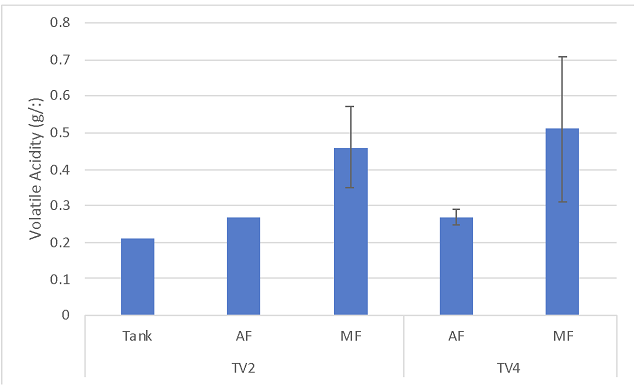

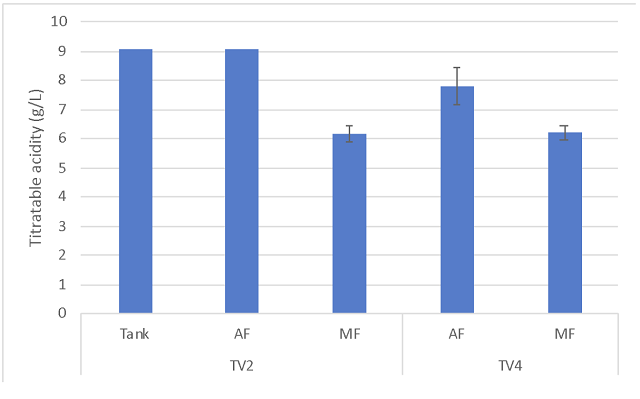

Fruit from the same vineyard block was picked over the course of 11 days in multiple picks and processed separately. Juice chemistry from three of these picks shows that, over the course of time, sugar increased slowly (0.2 Brix per day) with little change in pH but notable decrease in titratable acidity (Table 2). Wine chemistry is reported for two separate picks of fruit (Tables 3 & 4). In each case, 8 barrels were tested and designation was made based on the presence or absence of malic acid. In the TV2 lot, 7 of the 8 barrels spontaneously underwent malolactic fermentation while in the TV 4 lot, 5 of the 8 barrels showed full conversion of malic acid (Tables 3 & 4). Taken together, these barrels show that malolactic conversion led to lower titratable acidity, higher pH, and higher volatile acidity. The magnitude of difference is smaller in the TV4 lot as an artifact of the designation system. Several of the barrels designated as “AF” in lot TV4 underwent partial malolactic conversion, contributing to smaller differences between treatments and a higher level of variation within this treatment. Sensory analysis was limited to the TV2 lot for clarity.

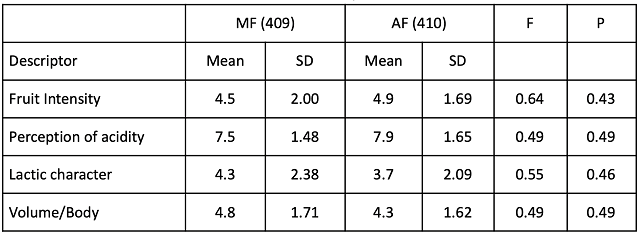

In a triangle test comparing a wine that underwent malolactic fermentation with a wine that did not (Flight 1), 16 out of 26 respondents were able to distinguish which wine was different, indicating the wines were significantly different (Z=2.84, p= 0.002). However, there were no significant differences in scores for fruit intensity, perception of acidity, lactic character, or volume/body (Table 5).

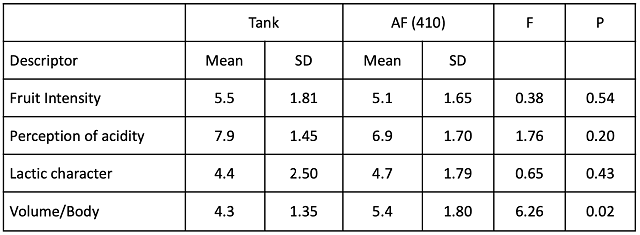

In a triangle test comparing wine fermented in tank vs neutral oak barrel (Flight 2), 11 out of 21 respondents were able to distinguish which wine was different, indicating the wines were significantly different (Z=1.62, p= 0.053). There were no significant differences in scores for fruit intensity, perception of acidity or lactic character, however there was a significant difference in scores for volume/body (Table 6).

Neither fermentation vessel nor occurrence of malolactic fermentation significantly changed the perception of acidity in these wines, despite notable changes in volatile acidity and pH.

Table 2: Juice chemistry for three picks of Chardonnay (in-house data)

Table 3: Wine chemistry for 8 barrels of TV2 Chardonnay (ICV labs)

Table 4: Wine chemistry for 8 barrels of TV4 Chardonnay (ICV labs)

Table 5: Statistical analysis for descriptive scores from blind sensory analysis of Flight 1 Chardonnay

Table 6: Statistical analysis for descriptive scores from blind sensory analysis of Flight 2 Chardonnay

Figure 1: Volatile acidity for five treatments of Chardonnay (ICV labs)

Figure 2: Titratable acidity for five treatments of Chardonnay (ICV labs)

References

(1) Bernardeau, M. Key Points to Sparkling Methode Traditionelle, 2017.

(2) Bernardeau, M. Base Wine Optimization Techniques: Key Tips for Award Winning Sparkling Rose Wines, 2018.

(3) Zoecklein, B. W. A Review of Methode Champanoise Production. Virginia Cooperative Extension 2002, No. Publication 463-017W.

(4) Jackson, R. S. Wine Science: Principles and Applications, 4 edition.; Academic Press: Amsterdam, 2014.