Hot Pre-fermentation Maceration in Merlot and Petit Verdot (2018)

Damien Blanchon

Afton Mountain Vineyards

Summary

The 2018 vintage presented many challenges in the vineyard and the winery. The occurrence of persistent rain throughout the growing season led to concerns of underripe fruit, Botrytis and other fungal diseases, lack of fruit flavors, and a compressed harvest. In this experiment, an open system using a propane heater and continuous pumping was set up to heat juice and return it to a fermentation vessel containing destemmed grapes. Heating continued until the fruit in the fermentation vessel reached 55°C (131°F). The fruit was allowed to cool prior to fermentation. Fermentation occurred on skins and seeds prior to pressing with the goal of increasing fruit flavors and flavors associated with ripeness and decreasing herbal character while avoiding cooked flavors and allowing for sufficient phenolic extraction. The same procedure was run on Merlot and Petit Verdot grapes. Heat treatment produced wines with higher pH and lower concentration of anthocyanins, skin phenolics and tannins that were distinguished as different from untreated wines in a triangle test. Heat treated Merlot scored higher for fresh fruit than untreated wines, while scores for structure and herbaceous/green character were not significantly different. Heat treatment in Petit Verdot did not lead to any significant differences in descriptors.

Introduction

The 2018 vintage presented many challenges in the vineyard and the winery. The occurrence of persistent rain throughout the growing season led to concerns of underripe fruit, Botrytis and other fungal diseases, lack of fruit flavors, and a compressed harvest. Pre-fermentation thermovinification is one technique that can be employed to address several of these concerns.

A common practice in France and Germany, some form of thermovinification has been present in the winemaking literature since the early 20th century. This practice became popular during poor vintages in France in 1960’s. Though begun on the small scale, eventually equipment was developed for large tonnages, quick heat, and liquid ferments (Nordestgaard 2017)

There are several ways heat can be used prior to fermentation. True thermovinification includes heating juice or must, pressing off the skins and seeds, cooling the juice, then fermenting the pressed juice. By contrast, pre-fermentation thermovinification, the technique used in this experiment, involves heating of juice or must, cooling, then fermentating on skins. Fermentation on skins after juice heating allows for a more normal extraction of seed tannins that depend on ethanol. (Nordestgaard 2017).

Thermovinification can provide several benefits to the resulting wine:

- Heat can denature laccase and other polyphenoloxidase enzymes, protecting the wine from oxidation (Patterson 2010).

- Heat increases the extraction of color, flavor and tannin from grapes that are relatively deficient in these qualities (Wagener 1981).

- Heating above 50°C (122°F) can remove green aromas such as those produced by C6 compounds and methoxypyrazine (Noordstgaard 2017).

- Fast extraction allows for early pressing, limiting the time on skins that may potentially carry disease organisms or fruit with undesirably harsh (underripe) seed tannins.

- Cooler fermentation after pressing may increasing fruit aromas (Patterson 2010).

- Due to quick press times, fermentation vessels can be freed up sooner, a benefit in compressed vintages (Noordestgaard 2017).

There are also drawbacks. True thermovinification can lead to poor color stability and lack of structure. Though anthocyanins are extracted quickly due to weakened cell walls, tannins need both time and the presence of ethanol for extraction. When they are not extracted, they are also not available to form polymeric pigments that stabilize color over time (Noordstgaard 2017).

On a chemical level, heat treatment of juice and must denatures the cell membranes that hold anthocyanins and other phenolics in cells, allowing faster extraction of these molecules. Diffusion processes also occur faster at higher temperatures. Heat treatment seems to stabilize the blue forms of anthocyanins, giving more purple hue to the wine. The effect of heat on other phenolics is unclear. Oszmianski et al (1986) tested the effects of the maceration of seeds in several conditions on phenolics and found that the presence of ethanol was needed for higher levels of phenolic extraction, even when carried out at 35°C (95°F). However, heat did increase extraction relative to non-heated extractions. Tests at 70°C (158°F) for one hour did not increase seed phenolic extraction. Patterson (2010) quotes one winemaker as saying he thinks “good” tannins (softer and rounder) come out with just heat and water while more “not so good” (harsher) tannins come out with ethanol as solvent.

Heating of juice may also affect flavor and aroma compounds other than phenolics. Linda Bisson hypothesizes that heat may volatilize several categories of compounds, including terpenes, thiols, and pyrazine. In juice, terpenes and thiols are still found as precursors (bound to sugars), so they are less likely to be lost at this stage than when fermentation gets hot. However, heat treatment may cleave aroma compounds from precursors earlier, the effect of which is not well defined. Heat treatment may also increase fruity esters, lactones, and fruity norisoprenoids (Patterson 2010)

Noordstgaard (2017) describes flavor profiles associated with true thermovinification and pre-fermentation solid phase thermovinification. True thermovinification can lead to wines with estery and fresh fruit aromas, little body and unstable color when grapes are green or have neutral aromas. Patterson (2010) says thermovinification allows a big boost of fruit, berry components with less complex wines overall, often taking away from varietal character. These are best used as a blending component. Pre-fermentation heating followed by a solid phase fermentation presents very ripe aromas with decreased green character (though it can still be present). These wines can have a wealth of tannins which may be hard and are thought to be better with aging.

Temperature is the most important consideration with thermovinification. Higher temperature leads to faster anthocyanin extraction rate. However, care must be taken as long periods over 80°C (176°F) can lead to cooked flavors. The speed of heating is also important if laccase is present. This enzyme denatures quickly over 70°C (158°F), however its peak activity is around 30-50°C (86-122°F) (Noorstgaard 2017).

There are many differences in procedures used for thermovinification. The basic approach is to warm the crushed grapes with a heat exchanger to 60°C (140 °F) for 1-24 hours; other machines heat to 52°C (125°F) for 24-48 hours (Patterson 2010). Heating is usually done by hot water or steam in either an open or closed system. Open systems can be heated hotter than closed systems with temperature targets of 65-70°C (149-158°F). These temperatures are hot enough to denature laccase, but open systems have more oxygen exposure. In closed systems, juice is not heated as hot (55-60 °C) which does not denature laccase, so SO2 is used up to 250-300 mg/L (Wagner 2010)

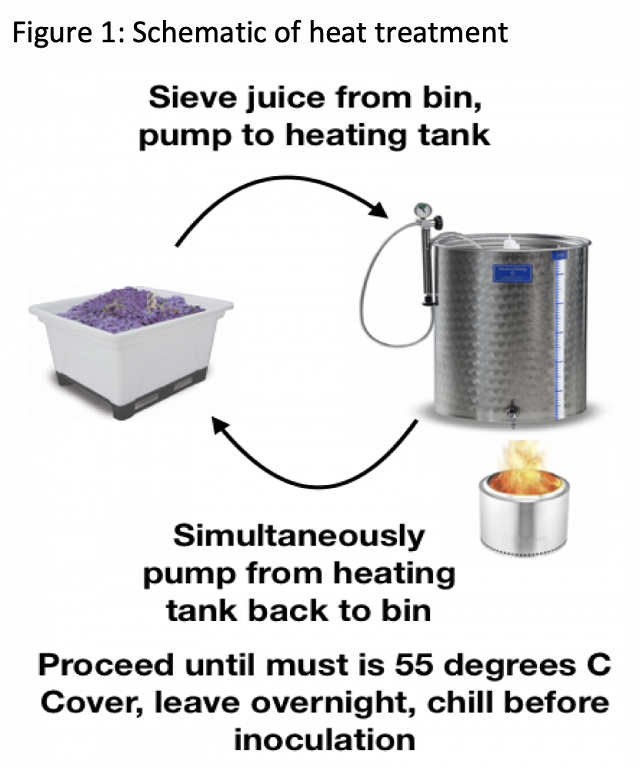

In this experiment, an open system using a propane heater and continuous pumping was set up to heat juice and return it to a fermentation vessel containing destemmed grapes. Heating continued until the fruit in the fermentation vessel reached 55°C (131°F). The fruit was allowed to cool prior to fermentation. Fermentation occurred on skins and seeds prior to pressing with the goal of increasing fruit flavors and flavors associated with ripeness and decreasing herbal character while avoiding cooked flavors and allowing for sufficient phenolic extraction.

Procedure

Merlot grapes were harvested and chilled overnight prior to processing. The following day, grapes were destemmed to TBin with addition of 30 ppm SO2 and 60 ml/ton Color Pro. There were two treatments:

- The control TBin was allowed to slowly warm in the cellar overnight prior to inoculation.

- The thermovinification bin was treated as follows (Figure 1):

A double pump system was set up to heat juice then return it to the fermentation. A sieve tube was used to pump juice from the TBin to a 3 hL receiving tank. This tank was placed above a small propane heater that heated the juice in the tank. Juice was then pumped back into the TBin to heat the must. Both pumps were running simultaneously to ensure juice did not overheat in the tank and take on a “cooked” character. Heating continued for 3 hours until the temperature of juice and must in the TBin reached 55°C (131°F). At that time, heating was stopped and all juice was returned to the TBin. The TBin was covered and allowed to sit in the cellar overnight. In the morning, the must was 45-50°C (113-122°F), so juice was pumped over the chilling paddle to cool the must to below 22°C (72°F) for inoculation.

After heat treatment, all other cellar operations were the same for both bins. Bins were inoculated with 20 g/hL Mt48 yeast rehydrated in 30 g/hL Go Ferm. Bins were pumped over for the first ⅓ of fermentation, then punched down twice daily. Chaptalization of 33 g/L was done at the peak of fermentation (when density was near 1030). There were no acid or nutrient additions. Fermentations were monitored daily for brix and temperature and pressed after the completion of primary fermentation. Wine was allowed to settle in tank for 6-7 days prior to transfer to barrel for malolactic fermentation. After all malic acid was consumed, 50 ppm SO2was added without racking.

Petit Verdot Procedure:

The experiment was repeated with Petit Verdot. All procedures for the Petit Verdot were the same as the Merlot except that the Petit Verdot control was fermented in tank while the treatment was fermented in Tbin. Both Petit Verdot fermentations were inoculated with CRVP yeast and chaptalized with 27 g/L sugar.

Sensory analysis

Sensory analysis was completed by a panel of 29 wine producers. Wines were presented blind in randomly numbered glasses. Panelists were presented with three wines, two of one type and one of another, and asked to identify which wine was different (a triangle test). They were then asked to score each wine on a scale of 0 to 10 for fresh fruit, structure and herbaceous/green character. Panelists were also given open ended questions to describe the wines. Merlot and Petit Verdot wines were presented in separate flights.

Results

Merlot grapes were harvested at 19.0 Brix with a pH of 3.6. Fermentation of the control juice was slightly slower than thermovinification of the heat-treated juice, presumably due to the cooler starting temperature. Both fermentations reached 33°C (91°F) for two days during fermentation (Figure 1) and both fermentations progressed strongly.

Petit Verdot fruit was harvested at 20.2 Brix with a pH of 3.6. Heat treated wine began at higher temperature than control wine, had overall higher temperature throughout fermentation and completed fermentation more quickly than treatment wine (Figure 1). Care should be taken when interpreting results from Petit Verdot vinification, as these were carried out in different types of vessels (tank vs. TBin) and at different temperatures, both of which may have had an impact on extraction of phenolics and conversion rate of sugar to alcohol.

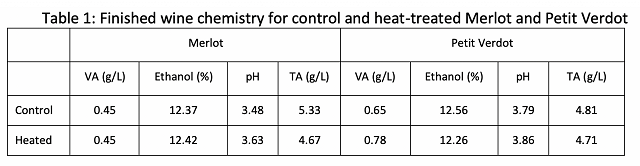

Heat treatment in Merlot led to higher pH and lower TA relative to control wine, with no change in VA or ethanol (Table 1). In Petit Verdot, the heat treated wine had lower ethanol and higher pH than control wine. Differences in acid may be due to higher levels of potassium extraction from the skins as a result of heating or greater metabolism of malic acid during heating. The difference in alcohol is likely due to higher temperature in the heat treated fermentation.

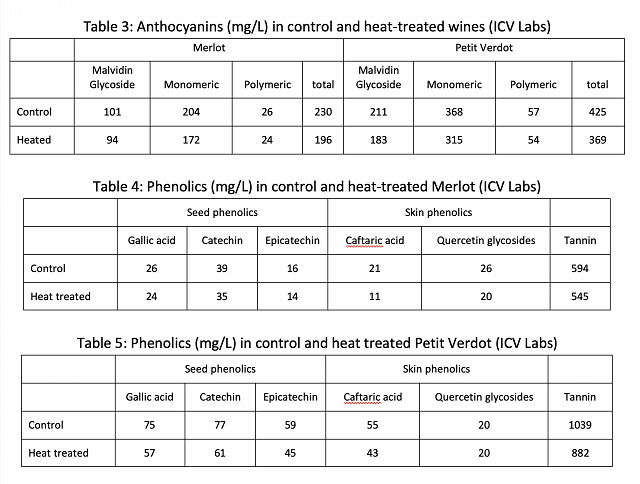

There was little difference in Merlot color (Figure 2) however the control wine had higher levels of anthocyanins, skin phenolics, and tannins (Tables 3 and 4). In Petit Verdot, there was little difference in color, but the control wine once again had higher anthocyanins, skin phenolics and tannins (Figure 2, Tables 3 and 5). Lower anthocyanin concentration in heat treated wine is likely due to anthocyanin loss during early release when tannins and other phenolics were not available to act as cofactors or form polymeric pigments. Pre-fermentation heating was followed by a strong fermentation on skins with the same amount of maceration time, which may have evened out differences in phenolic extraction.

In a triangle test of Merlot wines, 18 out of 29 respondents were able to distinguish which wine was different, indicating the wines were significantly different (Z=3.09, p=0.001). Control wine scored significantly lower for fresh fruit than heat treated wine (F=4.34, P=0.04) with an average of 4.31 out of 10 for control and 5.72 out of 10 for heat treated wine. There was no significant difference in scores for structure or herbaceous/green character in Merlot. There were no consistent trends in taster comments.

In a triangle test of Petit Verdot wines, 19 out of 29 respondents were able to distinguish which wine was different, indicating the wines were significantly different (Z=3.48, p<0.0003). There were no significant differences in scores for fresh fruit, structure or herbaceous/green character. Open ended questions indicate that tasters felt the control wine was more tannic, which some preferred and some did not.

Conclusions

- Pre-fermentation heating of juice changes the kinetics of fermentation including the speed and thermal environment. Warmer fermentations may decrease alcohol conversion. Though heating above 50°C (122°F) can remove C6 compounds and methoxypyrazine (Noordstgaard 2017), no difference was seen in herbaceous/green character in either wine. Both control and treated wines scored relatively low for this descriptor.

- Heat treated wines had higher pH than control wines.

- Control wines had higher concentration of anthocyanins, but the color was nearly the same between control and treated wines. These wines were analyzed within 8 months of harvest. Color differences may appear as the wines age.

- Control wines had higher concentration of skin phenolics and tannin, but sensory scores for structure were not significantly different.

- Despite having very similar scores for fruit, structure and herbaceous/green character, both Merlot and Petit Verdot wines were able to be distinguished in a triangle test, indicating the wines were different. Merlot heat treated wine scored significantly higher for fresh fruit than control, indicating this technique avoided cooked character sometimes associated with juice heating.

References

Girard, B., Kopp, T.G., Reynolds, A., Cliff, M. (1997) Influence of vinification treatments on aroma constituents and sensory descriptors of Pinot noir wines. Am J Enol Vitic 48 (2). 198-206.

Nordestgaard, S. (2017). Pre-fermentation heating of red grapes: A useful tool to manage compressed vintages? Grapegrower and Winemaker Feb 2017, 54-61.

Oszmianski, J., Romeyer, F.M., Sapis, J.C., Maceix, J.J. (1986) Grape seed phenolics: extraction as affected by some conditions occurring during wine processing. Am J Enol Vitic 37 (1), 7-12.

Patterson, T. (2010) Thermovinificaiton heats up interest. Wines and Vines Dec 2010.

Wagener, G.W.W (1981). The effect of different thermovinification systems on red wine quality. AJEV 32 (3), 179-184