Comparison of Juice Clarification Techniques (Cold Settling vs. Flotation) on Chemical and Sensory Aspects of Vidal Blanc (2016)

Joy Ting

Michael Shaps Wineworks

Summary

This study compares the efficacy of juice clarification with flotation to that of cold settling. The cold-settled juice fermented slightly slower. No notable chemical differences were apparent between juice and wine, except that cold-settled juice produced wine with a higher degree of cold stability. The TA was higher for the float-clarified wine. Wine produced from flotation resulted in less losses to gross lees, and reduced the need for chiller load. It could potentially reduce turn-around time as well, but this was not characterized fully in this study. A significant difference (p<0.001) between wines was found in triangle testing. Although descriptive analysis showed no strong trends for the descriptors used in this study there was a slight trend for wines produced with flotation to have higher Fruit Intensity as well as Overall Aromatic Intensity. In general, there was not a noticeable preference for the floated wine over the cold settled wine. These results suggest that flotation may be a beneficial technique not only to reduce turn-around time, enhance juice yield, and reduce chiller load; but that it may also serve as a mechanism for preserving aromatic intensity and fruit intensity.

Introduction

Clarification of white wine juice can be done using cold settling, flotation, or centrifugation. The traditional approach at Michael Shaps Wineworks has been cold settling at or near 32°F for 1-2 days. This takes considerable chiller capacity and time, exposes the juice to potential for oxidation (due to racking of cold juice), and ties up a tank for 1-2 days. This study explores the use of flotation as an alternative to cold settling. This approach uses bubbling of an inert gas through juice that has been treated with additives to float particulates out of the juice. To achieve flotation, juice must be treated with pectinase to break down haze forming proteins, and then treated with gelatin and bentonite to form floc along with silica gel to protect from overfining. Gas is bubbled for 2-3 hours, then the tank can be racked from the bottom valve until solids are encountered. Properly executed, this technique has comparable loss rates to cold settling, but occurs in a fraction of the time, freeing up tank space for the next press run.

Results and Discussion

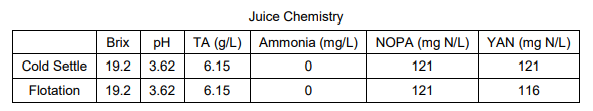

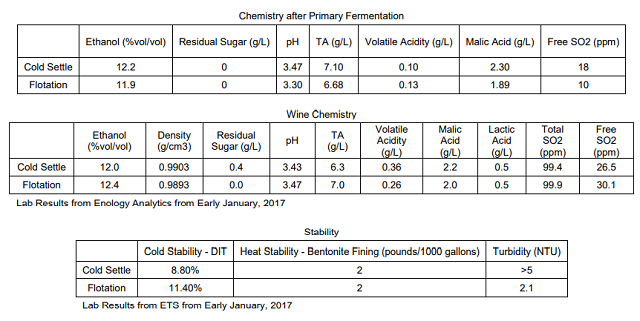

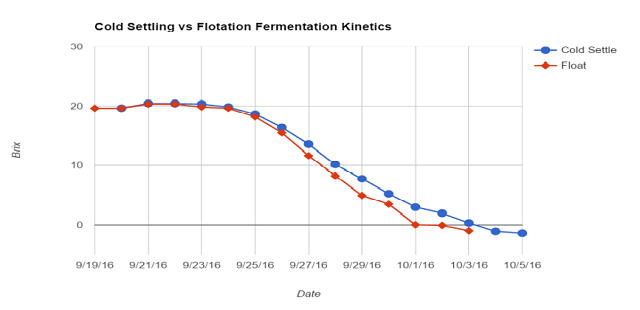

The cold-settled juice fermented slightly slower. No notable chemical differences were apparent between juice and wine, except that cold-settled juice produced wine with a higher degree of cold stability. The TA was higher for the float-clarified wine. Cold settling resulted in an approximate 7% loss of volume whereas flotation only resulted in approximately 2% loss (which could have been lowered if pumping was allowed to continue longer). This observation, however, was not fully quantified.

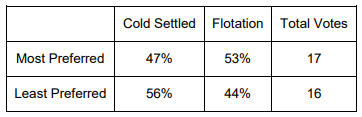

Of 33 people who answered the triangle test, 21 people chose the correct wine (64%), showing a statistically significant difference between wines (p<0.001). These wines were voted to have an average degree difference of 4.9 (out of 10) by those who chose correctly, suggesting that the wines were moderately different. In general, people who answered correctly did not have a preference for cold settled wine versus floated wine. Some judges described the floated wine as having a possible vinyl off-flavor.

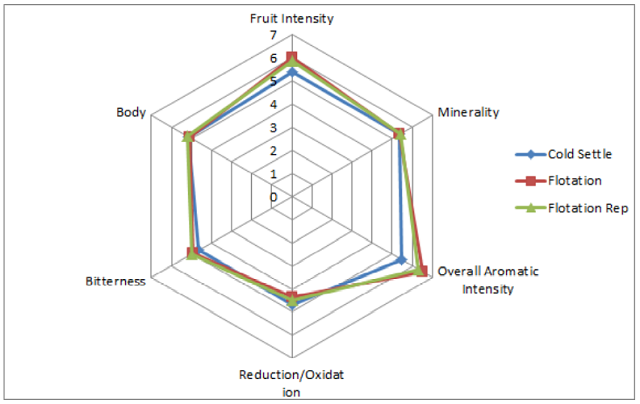

Despite a significant difference in triangle testing, there were no strong trends for the descriptors used in this study. However, there was a slight trend for wines produced with flotation to have higher Fruit Intensity as well as Overall Aromatic Intensity.

These results suggest that flotation may be a beneficial technique not only to reduce turn-around time, enhance juice yield, and reduce chiller load; but that it may also serve as a mechanism for preserving aromatic intensity and fruit intensity. This may be due to possible degassing brought about by the flotation process, the shorter time the juice remains uninoculated, the shorter amount of time juice is exposed to oxygen, or the treatment of the juice with fining agents. More study will be necessary to pinpoint what aspects of flotation affect these sensory qualities and to confirm these patterns and trends.

Methods

This is a comparison of techniques, and as such there were several differences between tanks. All juice originated from the same pick of Vidal Blanc grapes on 9/19. Harvest bins were weighed as a group, and they were pressed in the same press cycle and distributed evenly among experimental tanks.

For the control, grapes were crushed and de-stemmed before pressing into tank with the addition of sulfur dioxide and Cinn-Free in the tank. Glycol jackets were turned to 32°F for cold settling for one day. NTU were checked (as well as a pectin test using Laffort Pectin Test Kit) prior to racking. Once the NTU fell within an acceptable range (50-150 NTU), the juice was racked, the tank was gauged, pH and TA was determined, tartaric acid was added as needed to achieve a pH of 3.49 (0.75g/L), and must was inoculated with Alchemy 1 at 0.25g/L. Brix was adjusted with 16g/L sugar.

For the treatment, grapes were crushed and de-stemmed before pressing into tank with the addition of sulfur dioxide and Lafase XL Clarification (at a rate of 0.025 mL/hL), a strong pectinase designed for flotation. This sulfur dioxide addition was the same between treatments. After 2-3 hours, a pectin test was performed (using the Laffort Pectin Test Kit) to determine if all pectin had been broken down. The test was re-run every 30 minutes until no pectin precipitate was formed. After 5 hours, no pectin was detected.

Once pectin had cleared, must was treated with 0.05 g/L Vegecoll and 0.5 mL/L Siligel along with 0.3 g/L bentonite. Must was pumped through a Kiesel Float Clear with the addition of nitrogen gas for 30 minutes and allowed to float until juice was clear and a cap of float lees was formed. At this time, juice also reached a target NTU within the range of 50-150 NTU. Juice was then racked from the bottom valve until floc was encountered. Volume in the tank was gauged, pH and TA was determined, tartaric acid was added as appropriate to achieve pH 3.49 (0.75g/L), and then juice was inoculated with Alchemy 1 at 0.25 g/L. Brix was adjusted with 16g/L sugar.

Fermentation completed on 10/5, and on 10/6 35ppm sulfur dioxide was added. Sulfur dioxide levels were checked again on 11/7 and are listed as the Post-AF sulfur dioxide level. Samples were taken in December 2016, and sensory analysis was performed on January 25, 2017.

For the triangle test and preference analysis, anybody who did not answer the form were removed from consideration for both triangle, degree of difference, and preference. Additionally, anybody who answered the triangle test incorrectly were removed from consideration for degree of difference and preference. Any data points for preference which did not make sense (such as a person ranking a wine and its replicate at most and least preferred, when they correctly guessed the odd wine) were also removed.

For descriptive analysis, any judge that did not completely rank the wines were removed from the data set. Then, one judge was transferred from Group 3 to Group 1, and two judges from Group 3 were removed to balance the data set. All judges were divided into 3 groups, each with 8 judges. For statistical purposes, judges were considered replicates and groups were considered judges. Data was analyzed using PanelCheck software V1.4.2. Because this is not a truly statistical set-up, any results which are found to be statistically significant (p<0.05) will be denoted as a “strong trend” or a “strong tendency,” as opposed to general trends or tendencies. The statistical significance here will ignore any other significant effects or interactions which may confound the results (such as a statistically significant interaction of Judge x Wine confounding a significant result from Wine alone). The descriptors used in this study were Fruit Intensity, Minerality, Overall Aromatic Intensity, Reduction/Oxidation (a scale from most reduced to most oxidized), Bitterness, and Body.