Comparing effects of must concentration methods in Cabernet Franc (2018)

Matthieu Finot

King Family Vineyards

Abstract

In Virginia, wet vintages like 2003, 2011 and 2018 as well as more frequent fall rains and occasional hurricanes sometimes lead winemakers to pick grapes with lower potential alcohol than desired. Winemakers are then left with the decision of whether to intervene to augment the potential alcohol or not intervene and make a lower alcohol wine. Several options for increasing sugar include chaptalization, addition of juice concentrate and reverse osmosis of juice to remove water. The present study is an examination of interventions to improve wine quality in a challenging vintage. Cabernet France juice was either concentrated through reverse osmosis or saignée followed by chaptalization. The resulting wine was analyzed for chemical and sensory properties. In an extension of this study, wine was further treated with either a mixture of enological products for body and structure including a lees autolysis product (Surli Round, Enartis) and a tannin product (VR Grape, Enartis), or a second round of reverse osmosis of the finished wine. Chemical and sensory outcomes were evaluated 6 months after completion of primary fermentation. Treatment of juice with saignée and chaptalization produced a wine that was distinct from treatment of juice by reverse osmosis in a triangle test. However, none of the descriptors tested were significantly different. Reverse osmosis of both juice and wine resulted in wine with higher alcohol, TA, color intensity, anthocyanin content, and tannin than the other treatments. The highest level of tannin was found in the whole cluster treatment, despite having no juice concentration. Whole cluster fermentations also led to higher volatile acidity. Addition of enological products (yeast lees derivatives and tannins), even at relatively high levels, did not significantly change taster preference for the wine, nor perception of fruit, body, herbaceous/green character or structure.

Introduction

In Virginia, wet vintages like 2003, 2011 and 2018 as well as more frequent fall rains and occasional hurricanes sometimes lead winemakers to pick grapes with lower potential alcohol than desired. Winemakers are then left with the decision of whether to intervene to augment the potential alcohol or not intervene and make a lower alcohol wine.

Several options for increasing sugar include chaptalization, addition of juice concentrate and reverse osmosis of juice to remove water. Chaptalization adds only sugar and does not address concerns about flavor dilution, though chaptalization alone has been shown to increase sensory perception of ripeness (Sherman et al 2017). Adding concentrate brings concerns such as the potential for Zygosaccharomyces infection and the addition of phenolics disproportionate to the treated juice (Jackson 2014). Juice concentrate addition is not allowed for wines entered in the Virginia Governor’s Cup unless the concentrate is produced from Virginia fruit (J. Rose, personal communication). Reverse osmosis of juice to remove water not only increases potential alcohol but also concentrates flavor and structure that may be diluted in wet vintages while maintaining the terroir and appellation of the fruit.

Reverse osmosis of juice has been utilized in Europe in wet years since the 1980’s to “squeeze” the rain out of the juice to obtain flavor concentration and alcohol balance. This technique has been utilized in Bordeaux, Burgundy, Tuscany, Piedmont of Italy, and is used frequently in cool climate regions such as Germany (Goode 2014). EU regulations allow RO of juice but limit must concentration to 20% of the volume of the juice.

Reverse osmosis works by using pressure to force molecules across a membrane against a concentration gradient. Osmosis is the movement of water in response to a chemical gradient by diffusion. Water moves by osmosis from areas of low solutes to areas of high solutes, which lowers the gradient between areas. Solutes are separated by a semipermeable membrane and will pass through that membrane until differences are evened out on either side. If the membrane does not permit some materials to pass, for example, only small molecules can fit though the pores in the membrane, the remaining molecules will maintain a gradient, and water will move the opposite direction to even it out (Jackson 2014).

During wine filtration, there is a gradient of materials maintained on the retaining side of the membrane, creating osmotic pressure for water to move to the retaining side. Reverse osmosis filtration exerts physical pressure to overcome the osmotic pressure (Jackson 2014). Wine contains many large molecules that are retained by the filter, which leads to fouling of the membrane. Fouling is partially offset in reverse osmosis by the design of the filters which contain long tubes with high amounts of surface area for filtration and the flow of the wine in turbulent cross-flow currents (Smith 2014, Goode 2014).

Reverse osmosis membranes are not absolute filters, but rather layered web-like frameworks through which molecules must find their way through the “torturous path” (Ghosh et al 2015). Reverse osmosis membranes have a pore size rating of 80 Daltons which means that molecules of 80 Daltons will pass through the membrane 50% of the time. Water has a pore size of 18 Daltons and passes easily through RO membranes while most other constituents of juice, including sugar and molecules that contribute to flavor are larger than this (Smith 2014). Most flavor molecules are still bound to sugars at the juice stage and are more likely to be retained in the juice during reverse osmosis. Once cleaved/released during fermentation, these molecules are smaller, so larger pore sizes can be used for reverse osmosis of juice than for wine without losing flavor.

Complications of juice RO

There are several complicating factors when performing reverse osmosis on juice. Due to very small pore sizes, reverse osmosis filters clog quickly with particulates, so juice must be clarified to less than 200 NTU prior to filtration. Clarification is a normal step in white winemaking. However, for red wines, juice must be bled off the skins and clarified prior to RO, then returned to the must after treatment (Goode 2014). Even in clarified juice, pectin and pulp can clog the membranes. To increase the overall surface area for filtration, long tubes are needed, but the cross section of the tubes must be fatter than with wine filtration (Smith 2017).

High pressure is needed to raise Brix levels of juice. Sugar is a solute that exerts osmotic pressure. Two bars of osmotic pressure are added to the juice for each degree of Brix. As the juice is concentrated, additional pressure is needed to maintain reasonable flux rates on the filter. Figure 1 (from Duitschaever et al 1991) demonstrates the slowing flux rates for juice at ascending degrees of sugar. This same graph applies as juice is concentrated unless additional pressure is added throughout the filtration run. For example, at 21 Brix, 40 bar of pressure is needed simply to maintain the gradient. This leads to the need for high pressures to accomplish concentration (Smith 2017).

High pressure flow also means high amounts of friction and heating. Heat increases permeability of the membrane which means the potential loss of flavor and can also lead to cooked flavors. At high levels, heat can damage the membrane of the filter (Ferrarini et al 2001). To counter the buildup of heat, juice must stay cold during operation. For the RO unit used in this study, the product of temperature x pressure could not exceed 1350. As wine heated up during treatment, after a period of time allowable pressure is too low to accomplish further concentration, thus limiting operations (M. McGeary, personal communication).

RO vs. Chaptalization or Addition of Concentrate

Reverse osmosis has a greater impact on the chemistry of the wine than chaptalization alone. In a study comparing musts and wines made with chaptalization verses RO to the same 20 L fermentations, Duitschaever et al (1991) found that reverse osmosis increased must TA by 25-28% with 4°Brix increase while there was no change in TA due to chaptalization to the same sugar target. Tartaric and malic acid increased with reverse osmosis (30 and 38%, respectively). There were no significant changes in pH with either treatment. These differences persisted in wine, where the TA from RO wines were higher than that from chaptalization, though the tartaric acid mostly dropped out during cold stabilization. pH of the wine remained the same for both treatments. Volatile acidity was also higher in RO wines than chaptalized wine. In a study comparing wines made by concentrating juice with reverse osmosis to those made with the addition of juice concentrate, Pati (2014) found an increase in TA (5-7%), color (6-8%) and total phenol content with membranes that were not found in wines with addition of juice concentrate. Once again there was no change in pH with any treatment. Sensory analysis of these wines showed wines made with reverse osmosis of juice had better color; taste and odor were mixed results.

Lees and Tannins

In addition to low potential alcohol, wet vintages often lead to dilution of body and structure in the resulting wine. One approach to improving body is the addition of yeast lees to increase polysaccharide levels in the wine. Fine lees from the original fermentation can be added back after settling. Alternatively, yeast lees and their autolysis products are available from enological products. Wet vintages may also lead to short maceration times to avoid microbial contamination. Short maceration also means less time for extraction of phenolic compounds, leading to lack of structure in the resulting wine. Exogenous tannins from various sources are available from enological product companies.

The 2018 in Virginia included high amounts of rainfall. The present study is an examination of interventions to improve wine quality in a challenging vintage. Cabernet Franc juice was either concentrated through reverse osmosis or saignée followed by chaptalization. The resulting wine was analyzed for chemical and sensory properties. In an extension of this study, wine was further treated with either a mixture of enological products for body and structure including a lees autolysis product (Surli Round, Enartis) and a tannin product (VR Grape, Enartis), or a second round of reverse osmosis of the finished wine. Chemical and sensory outcomes were evaluated 6 months after completion of primary fermentation.

Procedure

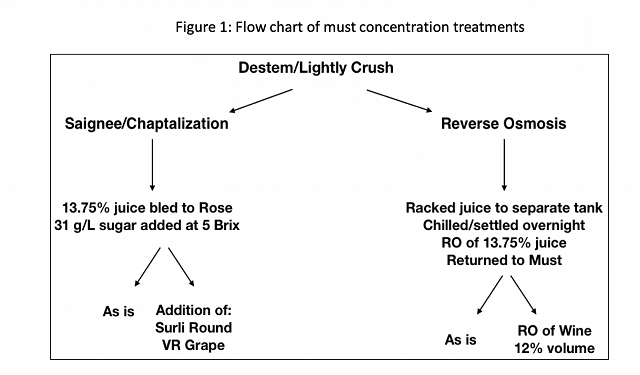

This is a “protocol” comparison, so there will be multiple variables between treatments. There were four treatments total (Figure 1). For each treatment, grapes were destemmed and lightly crushed with the addition of 21ppm SO2, 0.05g/hL Lafasse HE Grand Cru and 1.4 g/L mini chips bois frais. There were two sets of TBins:

- Saignée and chaptalization: As soon as the tank was filled, 13.75% of the juice by weight was bled into a tank for Rosé. At this stage, the standard winemaking practices of the winery were employed, with chaptalization of 31 g/L to the same potential alcohol target as the RO treatment.

- Reverse Osmosis: As soon as the tank was filled, juice was racked to a separate tank, chilled and clarified overnight, then treated with reverse osmosis to remove 13.75% of the water by weight. Reverse osmosis treatment was carried out using a Bucher Vaslin Flavy ML Osmoser Machine. The machine was run between 60-90 bar of pressure and wine at a range of 5-25°C with a maximum pressure x temperature of 1350. For example, if the wine was at 20°C the maximum pressure would be 67.5 bar (1350 = 20 x 67.5) so as not to damage the membrane. Treatment began with juice at 5°C running at 88-90 bar. As the juice heated up during processing, at 15°C the operator would lower the pressure to maintain pressure x temperature less than 1350. Lower than 67.5 bar, the rate of RO was slower than was useful for processing. The machine operated at 150 L/hour initially but slowed to 20 L/hour when at lower pressure. Remaining juice was then returned to the tank holding the skins and seeds of the grapes. After RO, brix of the remaining juice was measured. This provided the target Brix for chaptalization of treatment 1.

After the initial must concentration step, all remaining winemaking procedures were the same (with the exception of chaptalization at 1.020 for the saignée bin). Each fermentation was inoculated with 7 g/hL Fermol Premier Cru yeast rehydrated in water and juice. Acid additions were the same between bins and Fermoplus Premier Cru (AEB) nutrient was added 1/3 of the way through fermentation. Wine was pressed on the same day (10/4) and transferred to barrels for malolactic fermentation. At the completion of malolactic fermentation, 66 ppm SO2 was added along with 0.03 g/L Stab Micro, a chitosan product.

Two additional treatments were added after the completion of malolactic fermentation. Each lot was split so that wine from the original treatment could be used as a control while a subset of the wine received an additional treatment.

- The wine that was concentrated by saignée and chaptalized received an addition of Surli Round (0.4 g/L) and VR Grape (0.3 g/L) to increase mouthfeel and perceived structure to the wine resulting from saignée and chaptalization. This was meant to represent a continuation of a traditional approach to building body and structure.

- The wine resulting from reverse osmosis of juice received a second round of reverse osmosis with and additional 12% of the volume removed resulting in a total of 25.75% of the original volume removed.

A fifth wine was produced from this lot of grapes and is included here for demonstration purposes. This lot was fermented as whole clusters in a closed stainless steel tank. The clusters were foot stomped to produce enough juice to pump over daily and juice was chaptalized with 31 g/L sugar.

Sensory analysis was completed by a panel of 29 wine producers. In the first flight, wines from the initial treatments (saignée plus chaptalization and reverse osmosis of juice) were presented blind in randomly numbered glasses. Panelists were presented with three wines, two of one type and one of another, and asked to identify which wine was different (a triangle test). They were then asked to score each wine on a scale of 0 to 10 for red vs. dark fruit flavor, herbaceous/green character, and ageability. Panelists were also given open ended questions to describe the wines. In a second tasting flight, tasters were presented with all four wines and asked to score the wines again for the same descriptors, as well as rank the wines from least preferred to most preferred.

In a second sensory session, the wine produced from saignée and chaptalization of juice was presented in a paired preference test with the same wine to which additions had been made. Panelists were asked to rate the wines for red vs. dark fruit flavor, herbaceous/green character, body and structure.

Results

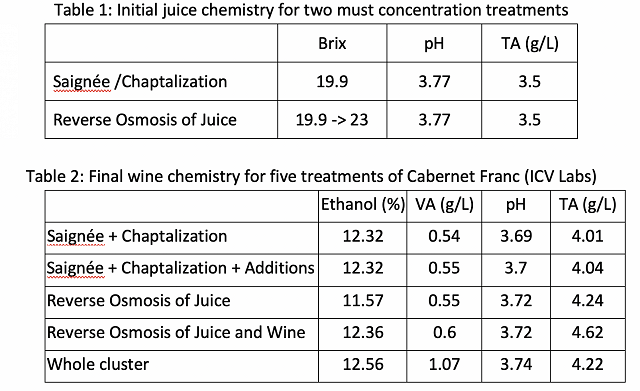

Initial juice chemistry was the same for both lots, with no difference in pH or TA resulting from juice concentration by reverse osmosis (Table 1). Reverse osmosis treatment led to wine with lower alcohol and slightly higher TA than chaptalization (Table 2). Reverse osmosis of wine led to an increase in alcohol relative to reverse osmosis of juice alone (from 11.57% to 12.36%) as well as slight increases in volatile acidity and TA. Whole cluster wine had noticeably higher volatile acidity.

Phenolics

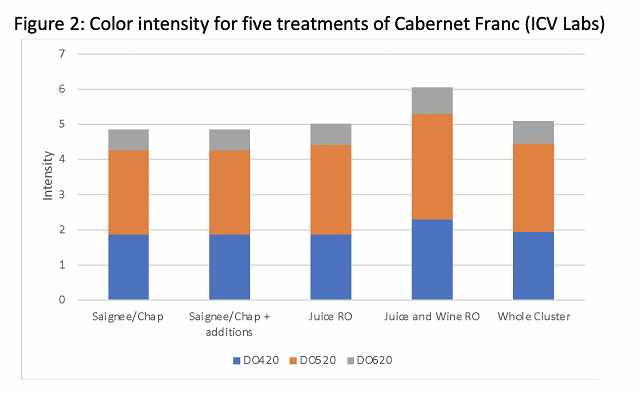

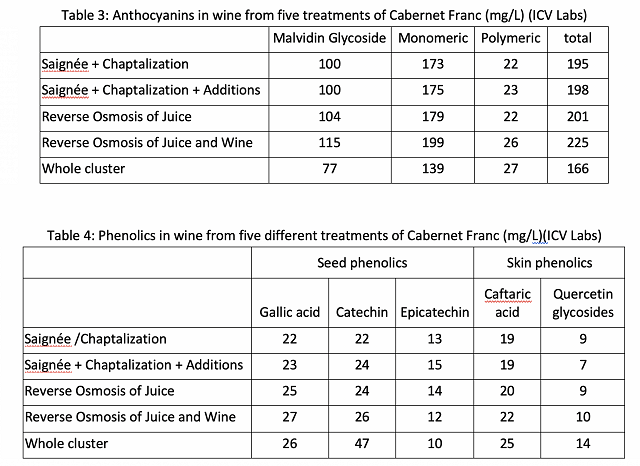

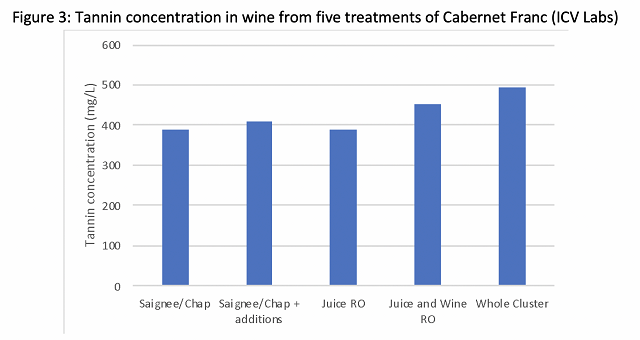

Wine color intensity and anthocyanin concentration were higher in the wine that received two rounds of concentration by reverse osmosis while reverse osmosis of juice alone did not noticeably improve either of these metrics. Skin and seed phenolics were not notably difference for any of the treatments with the exception of whole cluster fermentation, which had higher levels of catechin (Table 4). Though catechin is listed under seed phenolics in Table 4, it is also found in stems, this likely source of higher levels in a whole cluster fermentation. Tannin concentration increased with addition of exogenous tannin as well as reverse osmosis of juice and wine, though reverse osmosis of juice alone did not increase tannin levels in the resulting wine (Figure 3). Whole cluster fermentation led to the highest level of tannin, despite having no juice concentration (neither saignée nor reverse osmosis).

Sensory

In a triangle test comparing saignée + chaptalized wines with those receiving juice RO, 15 out of 29 respondents were able to distinguish among the wines, indicating the wines were significantly different (Z=1.9, p=0.03). There were no significant differences in scores for red fruit flavor, herbaceous/green character or ageability. In a separate comparison of all four treatments, there were no significant differences in perception of herbaceous/green character or ageability, however there was a significant difference in perception of fruit quality between juice RO treatment and juice + wine RO treatment. Here, wines produced from juice RO were perceived as having more red fruit character while wines produced from reverse osmosis of both juice and wine were perceived as having more dark fruit character, with means of 4.41 (SD=1.99) and 5.85 (SD=1.83) respectively on a scale where 0 represented red fruit and 10 represented dark fruit (p=0.03, Tukey HSD). No other pairwise comparisons were significant. When asked to rank the wines from least preferred to most preferred, there were no significant differences in average ranking for any of the wines (Friedman’s Test Q=5.61, p=0.13).

At a separate tasting, a panel of 11 wine producers was asked to indicate a preference for either the wine produced from saignée + chaptalization or the same wine which had received additions of Surli Round and VR Fruit. Seven out of eleven tasters chose the wine with Surli Round and VR Fruit, however this difference is not significant (p=0.28). There were also no significant differences in scores for red fruit, herbaceous/green character, body, or structure.

Conclusions

- Treatment of juice with saignée and chaptalization produced a wine that was distinct in a triangle test from treatment of juice by reverse osmosis. However, none of the descriptors tested were significantly different.

- Reverse osmosis of both juice and wine resulted in wine with higher alcohol, TA, color intensity, anthocyanin content, and tannin than the other treatments.

- Reverse osmosis of juice alone did not greatly improve color or phenolics.

- The highest level of tannin was found in the whole cluster treatment, despite having no juice concentration. Whole cluster fermentations also led to higher volatile acidity.

- Addition of enological products (yeast lees derivatives and tannins), even at relatively high levels, did not significantly change taster preference for the wine, nor perception of fruit, body, herbaceous/green character or structure.

References

- Jackson, R. S. (2014). Wine science: Principles and applications. London: Elsevier/Academic Press.

- Sherman, E., Greenwood, D.R., Villas-Boas, S.G, Heymann, H., Harbertson, J.F. (2017) Impact of Grape Maturity and Ethanol Concentration on Sensory Properties of Washington State Merlot Wines. Am J Enol Vitic 68(3), 344-356.

- Goode, J. (2014) The Science of Wine: From Vine to Glass. University of California Press; Second edition.

- Smith, C. (2014). Postmodern Winemaking: Rethinking the Modern Science of an Ancient Craft by Clark Smith. University of California Press

- Duitschaever, C.L., Alba, J., Buteau, C., Allen, B. (1991) Riesling Wines Made from Must Concentrated by Reverse Osmosis. I. Experimental Conditions and Composition of Musts and Wines. Am J Enol Vitic 42(1) 1991.

- Ghosh, P., Singh Rana, S., Kumar, S., Rama Chandra Pradhan, C, and Mishra, S. (2015) Membrane filtration of fruit juice – an emerging technology. Int J Food and Nutr Sciences 4(4) 47-57.

- Ferrarini, R, Versari, A., Galassi, S. (2001) A preliminary comparison between nanofiltration and reverse osmosis membranes for grape juice treatment. J of Food Eng 50, 113-116.

- Pati, S., La Notte, D., Clodoveo, M.L., Cicco, G., Esti, M. (2014) Reverse osmosis and nanofiltration membranes for the improvement of must quality. Eur Food Res Technol 239, 595-602.